Microgel to Bioconcrete: Tiny to Big

Published in Bioengineering & Biotechnology

As ever, the Professor Yong He group, namely Engineering for Life (EFL) group, has been an energetic interdisciplinary researching team focusing on 3D bioprinting. I began to join Prof. He's team in September 2016 as a Ph.D. candidate. As usual, Prof. He puts a premium on individualized education and the development of our creative personality. Thus, our "researching whims" are always respected and supported by him. Since the outbreak of COVID-19 pandemic at the end of 2019, people from all over the world have been facing lots of difficulty and challenge. The dilemma highlights the importance of biomedicine and arouses the thinking of researchers in this field, as well as the interdisciplinary researchers as us in the field of biofabrication. With the recovery of the pandemic, we gradually went back to lab after Chinese new year in 2020. Taking the consideration of biofabrication development, I decided to come up with an innovative invention for clinical biomedicine with 3D bioprinting.

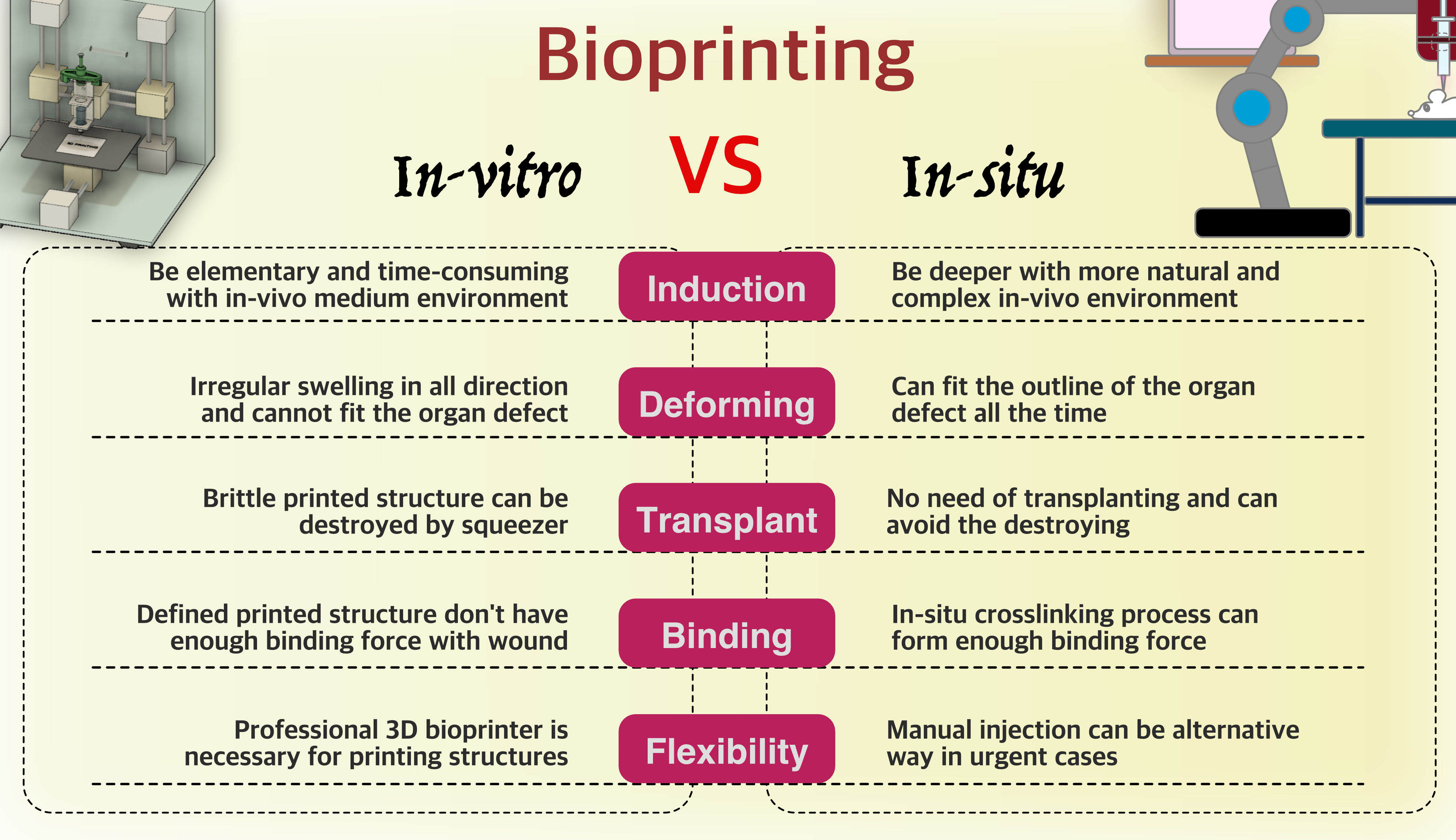

Occasionally, I saw a report about an emerging bioprinting technology "in-situ bioprinting", namely directly depositing bioink on the organ injury to decrease the treatment duration and pain of patients. Compared to organ implantation based on traditional 3D bioprinting in vitro, in-situ bioprinting has more advantages for its in-situ deposition feature (Figure. 1). In-situ bioprinting can realize high shape suitability and avoid breaking up during structure transplanted. Because the bioink is crosslinked directly to the organ defect, the bioink can infiltrate the wound surface and spontaneously fills in the tiny gaps. After crosslinking, the internal friction between the bioprinted structures and the wound surface can be high. In-situ bioprinting can also utilize a more complicated and all-round stimulation environment in vivo to facilitate deeper functionalization of the bioprinted structures. Moreover, the flexibility of in-situ bioprinting is high. Even without a professional 3D bioprinter, manual operation or direct injection of the bioink can be an alternative strategy in some urgent situations (battleground, traffic accident), which is daunting in in-vitro bioprinting. Therefore, I regarded it as an effective strategy and would be one of the most important evolutions of 3D bioprinting. Thus, I talked to Prof. He about my initial idea and finally got his support.

Figure. 1 Superiority of in-situ bioprinting compared to in-vitro bioprinting

At first, we thought it would be extremely easy to carry out since the only procedure difference with the one in in-vitrobioprinting was the receiving platform (metal plate to animal tissue). Thus, we directly carry out in-situ bioprinting with the traditional GelMA bioink (precursor solution) and 3D bioprinter and fixed a rat with cranial injury on the receiving plate. We moved the 3D bioprinter into animal experiment room. However, we were really caught off guard by the actual operation. Firstly, for the thermo-sensitive of GelMA precursor solution, the rheological properties of the bioink cannot be stable in the animal experiment room which needs to maintain constant temperature. The bioink gradually transferred to rigid hydrogel and cannot form uniform filament for the extruding printing. We tried to set other temperatures of the injection part and narrowly form the filament for printing, but another difficulty occurred as the body temperature and blood environment around the rat injury made the deposited bioink totally crushed and mixed with blood. The printed 3D structure morphology cannot be maintained, much less the hydrogel/tissue binding force and mechanical properties of the printed structure. These factors pushed us to reconsider a special bioink system for particularly in-situ bioprinting situation. Some changes have to be made for the clinical in-situ bioprinting. Otherwise, it would only remain a concept rather than actual technology.

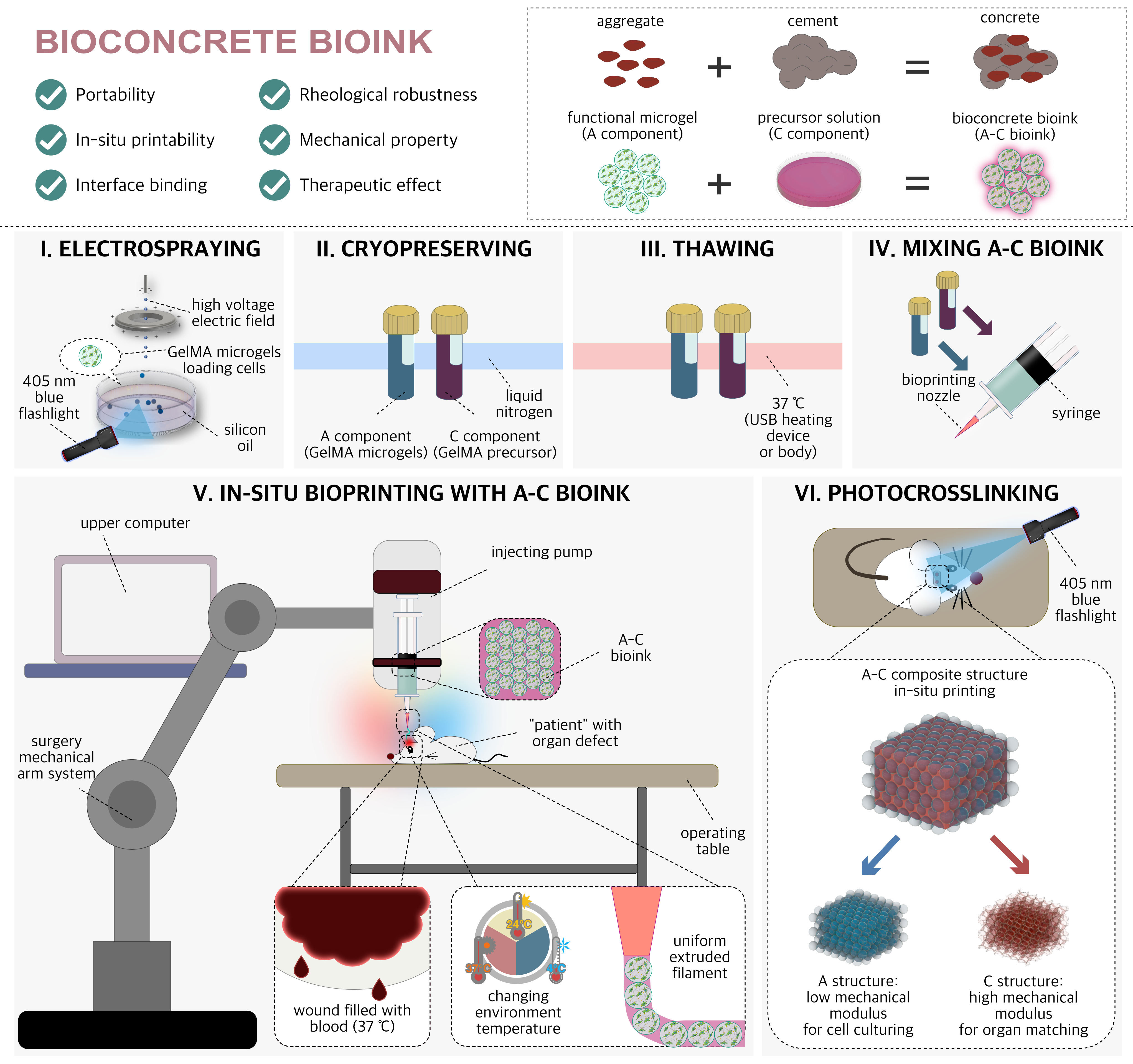

My Ph.D. researching topic is the fabrication of microgels with electrohydrodynamic principle. One weekend, I was killing time in the cafe and reading a review paper published on Nature Reviews Materials by Burdick group about microgels, in which they summarized the fabrication methods of microgels and the emerging applications with microgels in detail. Among these applications, secondary bioprinting with microgels, namely using bioink loading microgels to print structures, really hit me. "Why not introduce microgel-based bioink to in-situ bioprinting?" Suddenly, construction noise came from outside, it turned out to be the workers who were repairing the wall of the building. Looking at the concrete on the ground, I was immersed in thought... That was when I decided to design the "bioconcrete bioink" with microgels to solve the previous problems in in-situ bioprinting. (Figure 2).

Figure.2 Train of thought of A-C bioink designing and sketch of the preparing/using method.

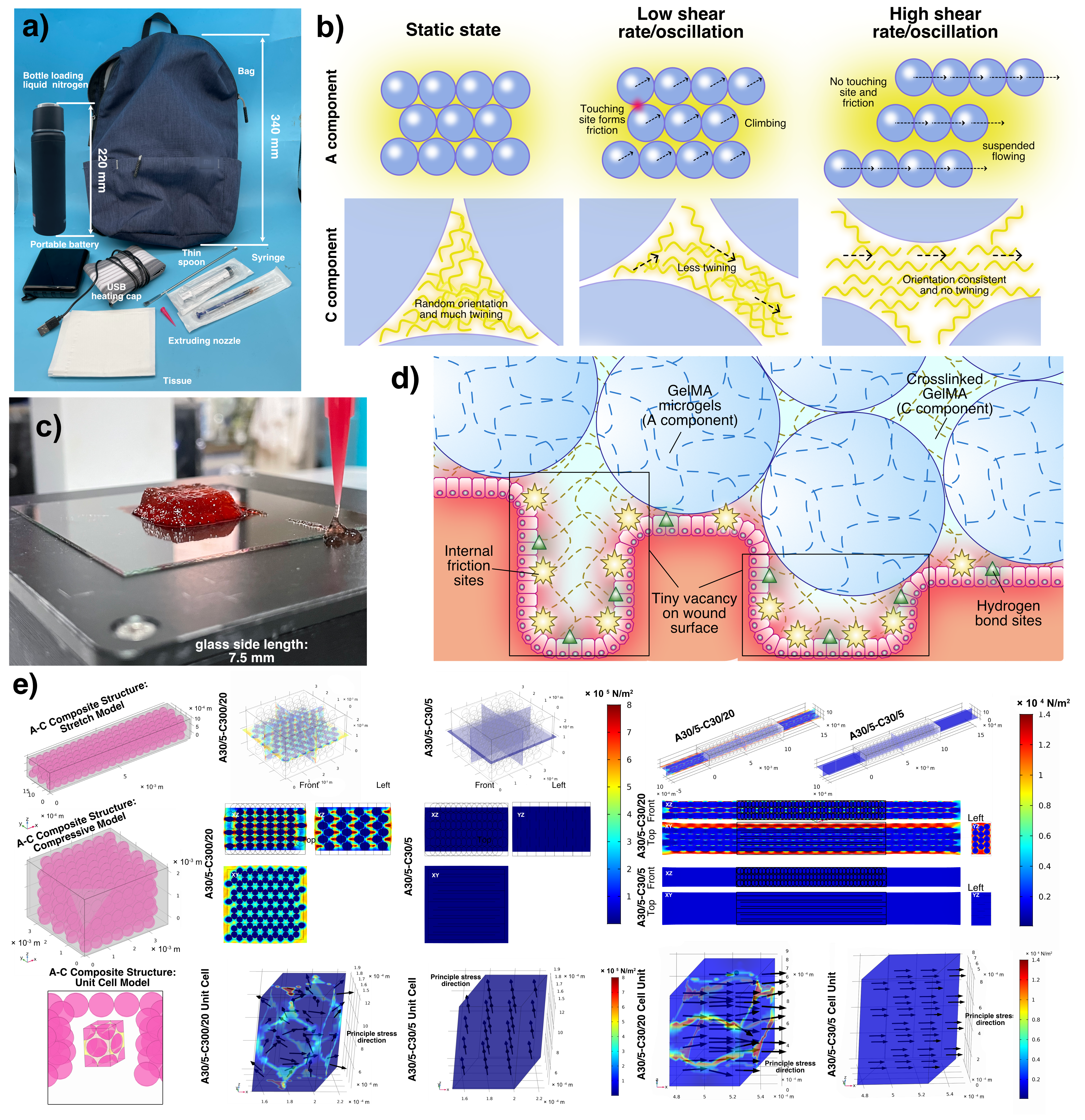

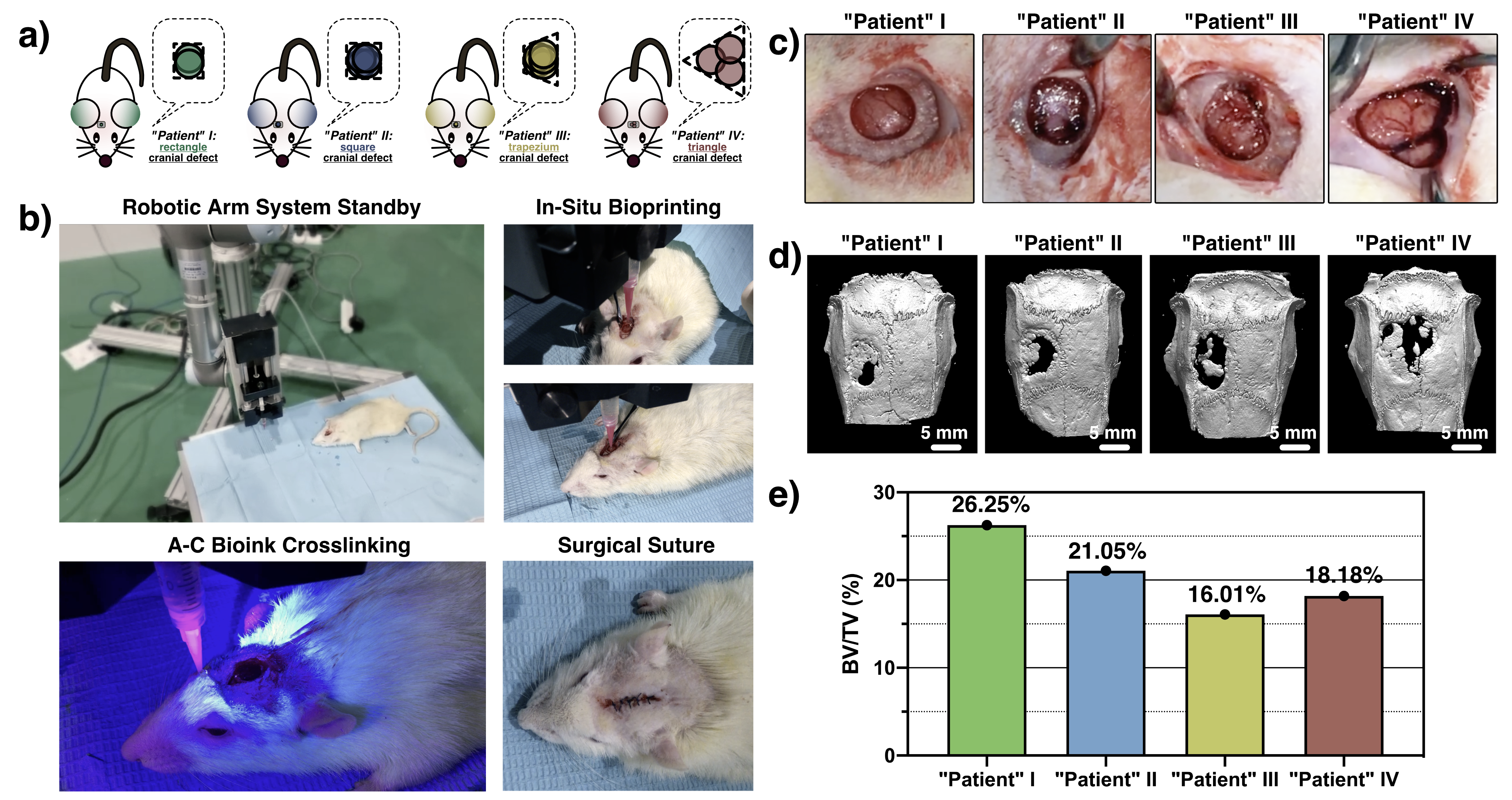

This idea turned out to be promising. Later, as you can see in our published work, we developed the bioconcrete bioink (A-C bioink) for in-situ bioprinting, the name of which comes from concrete for construction and its abbreviation comes from the two main components: aggregate (A) and cement (C). Electrosprayed GelMA microgels (500 μm) are used as the main (A) component to obtain robust rheological properties similar to Bingham fluid in complex environments. GelMA precursor solution (with photoinitiator) are used as the auxiliary (C) component to ensure the fluidity and printability. The photocrosslinked composite structure owns A/C structure with low/high mechanical modulus respectively, which perfectly solves the contradiction between maintaining biocompatibility for loaded therapy cells and bearing the high tensile/compressive stress around the defect. Additionally, C component can easily infiltrate the wound surface and form high internal friction and hydrogen bonds on defect-hydrogel interface after photocrosslinking. Conveniently, this bioink is portable because A/C component can be conserved in liquid nitrogen, which can be thawed with heating devices or body temperature in accidents (Figure 3). Meanwhile, the microgels can be cultured to mini tissues before mixing, indicating our bioconcrete bioink can be functionalized faster than traditional ones. The in-situtreatment results of rat cranial defects verify its potential in clinical settings in in-situ bioprinting in the future (Figure 4).

Figure.3 Advantages of bioconcrete bioink. a) Portability. b) Rheological robustness. c) Printability. d) Tissue binding force. e) Composite mechanical property.

In the future, A-C bioink can be designed in more ways. For A component, cell species in A component can be changed for more functions. For C component, GelMA is the only biomaterial applied here and other biomaterials could be as substitutes such as hyaluronic acid methacryloyl (HAMA) with high mechanical adjustability. Furthermore, considering the portability and multi-scene feasibility, we call on the development of intelligent and carry-home equipment for A-C bioink in-situ bioprinting in the future. As an assumption, a compositive bottle integrated heating device, portable battery and flashlight could be designed. Furthermore, from an urban development standpoint, “nitrogen stations” like petrol stations and “shared handheld in-situ bioprinters” like shared bicycles can be established at public positions as social service, so that the long-term storage of A-C bioink in long journeys and the immediacy of in-situ bioprinting can be guaranteed.

Figure.4 In-situ bioprinting at rat cranial defect models with different morphology with A-C bioink. a) 3D structure morphologies of the rat cranial defect models. b) In-situ bioprinting steps with A-C bioink. c) Original "patient" cranial defect morphology. d) Micro-computed tomography examination after 6-week in-situ treatment. e) BV/TV value after 6-week in-situ treatment.

It is Sunday again, and I'm still in the cafe where the "bioconcrete idea" came to me. After 2-year researching, we finally solve varieties of challenges and get milestone of in-situ bioprinting with our effort. We believe that we will continue to try to contribute our strength to the development of biomedicine with our biofabrication technology and...you know...the "researching whims" (LOL^.^).

Is anyone interested in working with us? Please feel free to leave a comment below.

Follow the Topic

-

Nature Communications

An open access, multidisciplinary journal dedicated to publishing high-quality research in all areas of the biological, health, physical, chemical and Earth sciences.

Related Collections

With Collections, you can get published faster and increase your visibility.

Women's Health

Publishing Model: Hybrid

Deadline: Ongoing

Advances in neurodegenerative diseases

Publishing Model: Hybrid

Deadline: Mar 24, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in