Peeling-induced shape morphing of plastic film

Published in Materials

Three-dimensional (3D) architectures are highly desired for functional materials and electronic devices because they can accommodate more functions and offer better spatial resolution than those restricted to two-dimensional (2D) architectures. Unfortunately, methods to directly produce these 3D devices are limited, because most existing fabrication technologies such as spin coating, lithographic patterning etching, and thin film deposition constrain the substrates of devices to 2D or only simple macroscale 3D geometries. Shape morphing offers a promising method to transform 2D electronics into 3D structured devices.

However, current post-shape transformation strategies are limited to heterogenous or responsive materials, and are not amenable to free-standing inert plastic films, such as polyethylene terephthalate (PET), polytetrafluoroethylene (PTFE) and polyimide (PI), which are vital substrates for flexible electronics. Therefore, it is urgent and of great challenge to develop general strategy for the shape morphing of such uniform plastic films.

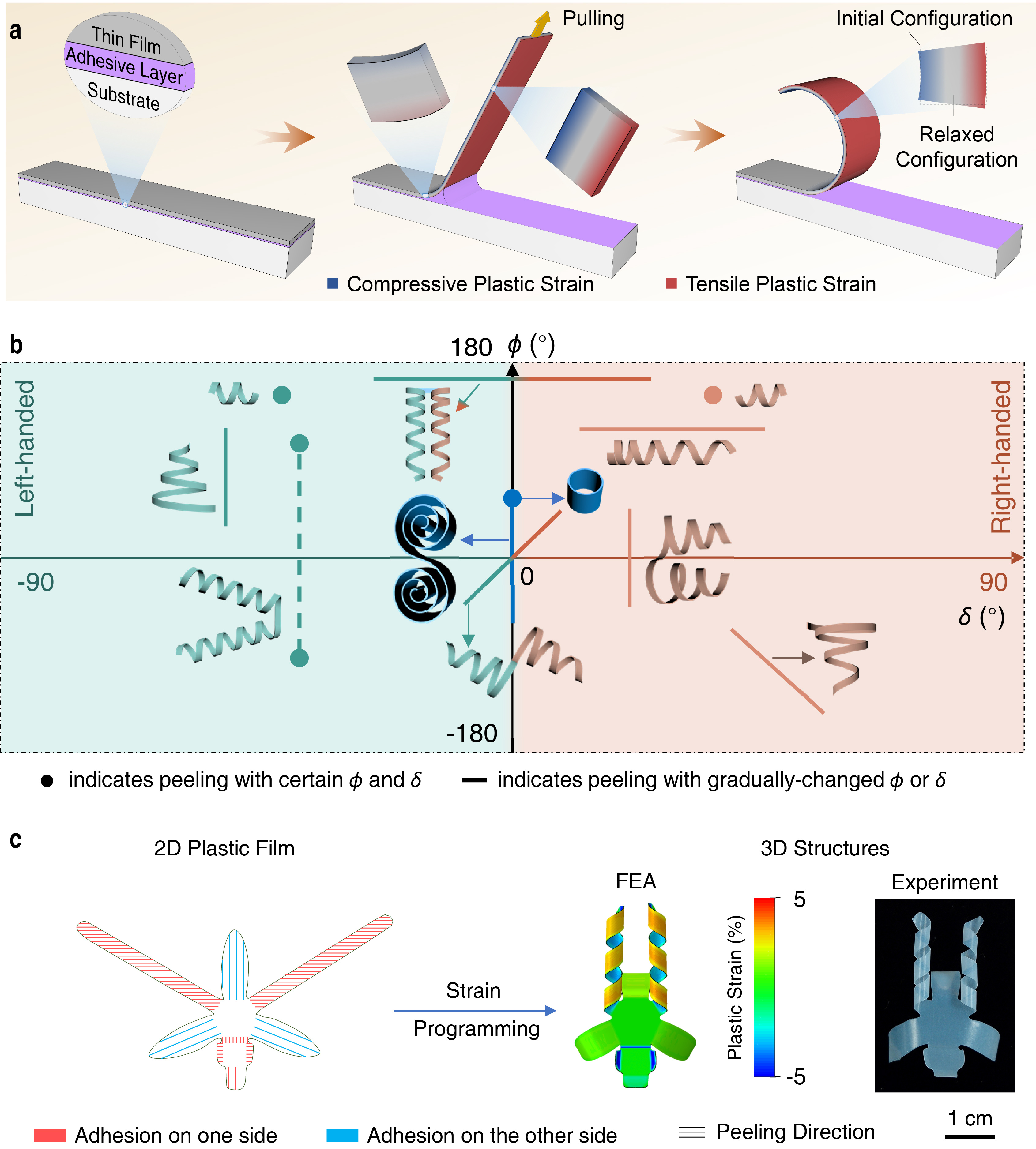

Here, we proposed an easy shape morphing strategy of homogeneous inert plastic thin films into free-standing 3D frameworks by programming the plastic strain in films under peeling. The peeling system includes an adherent film, an adhesive layer, and a substrate (Fig. 1a). During peeling, the asymmetric plastic strains are induced and maintained at the two sides of the film after peeling, which bent the plastic films (Fig. 1a). The asymmetric degree of plastic strains can be regulated by adjusting peeling parameters, such as peeling speed, adhesive thickness, film thickness, and peeling angle (ϕ). The strain orientation is controlled by varying deviation angles (δ). Adjusting these parameters can transform 2D precursors into complex 3D geometries as intended (Fig. 1b, c). This peeling-induced shape morphing strategy is applicable to various materials of polymers and metals, as well as multilayer films with at least one as plastic film. The experimental results are well supported by theoretical modelling and numerical analysis.

Figure 1 | A general strategy for shape morphing of inert plastic films by peeling. a, Schematic showing the peeling process involving the adherent thin film, adhesive layers, and substrate. b, Phase–like diagram of the peeling-induced 3D structures and the peeling process with ϕ and δ. The negative peeling angle indicates the other surface of the film was adhered. c, An orchid-like architecture with configurations of bending and helix from a 2D precursor film by peeling. Colors in the 3D FEA correspond to the maximum principal plastic strain.

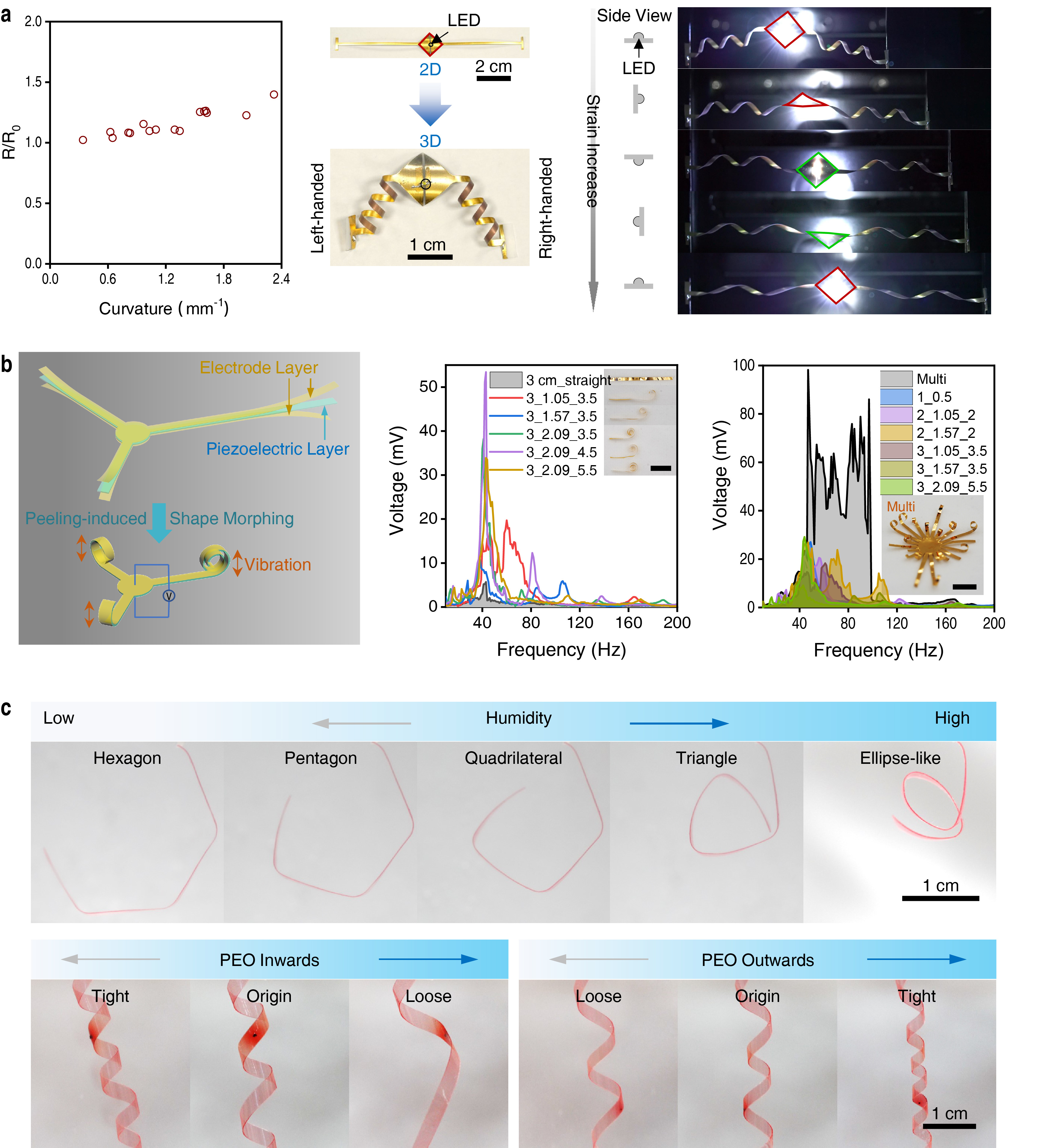

With the plastic films as substrates, the 2D circuits can be morphed into 3D ones of various structures with the resistance almost unchanged by peeling (Fig. 2a). The 3D circuits are endowed with extended functions, such as high stretchability and rotation under stretch (Fig. 2a). The planar plastic piezoelectric polymer systems could also be easily transformed into 3D shapes, enhancing the vibration-sensitivity, and extending the sensible vibrational frequency (Fig. 2b). This peeling-induced shape morphing strategy will be a great contribution to the field of soft electronics. Introducing this strategy to traditional responsive actuator field, the initial shapes of the actuators can be well accurately designed and fabricated. The obtained 3D-shaped responsive films could further change the shape under stimuli (Fig. 2c), call ed 4D shape transformation.

The proposed peeling-induced shape morphing is applicable to most materials capable of plastic deformation and other complex systems. This shape morphing strategy is expected to bring prosperity to soft electronics and stimuli-responsive actuators for 3D and 4D devices.

For more details, please check out our paper "Shape morphing of plastic films" in Nature Communications.

Follow the Topic

-

Nature Communications

An open access, multidisciplinary journal dedicated to publishing high-quality research in all areas of the biological, health, physical, chemical and Earth sciences.

Related Collections

With Collections, you can get published faster and increase your visibility.

Women's Health

Publishing Model: Hybrid

Deadline: Ongoing

Advances in neurodegenerative diseases

Publishing Model: Hybrid

Deadline: Mar 24, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in