Predicting material properties of unseen conditions

Published in Materials

Machine learning (ML) algorithms have taken a big leap in the past few years. Their applications are far-reaching, e.g., for autonomous driving, natural language processing, or speech recognition devices. ML-driven approaches have recently also gained high interest in material science. Such approaches are highly interesting to identify the influence of structures or morphologies ranging over different length-scales in relation to the property of interest.

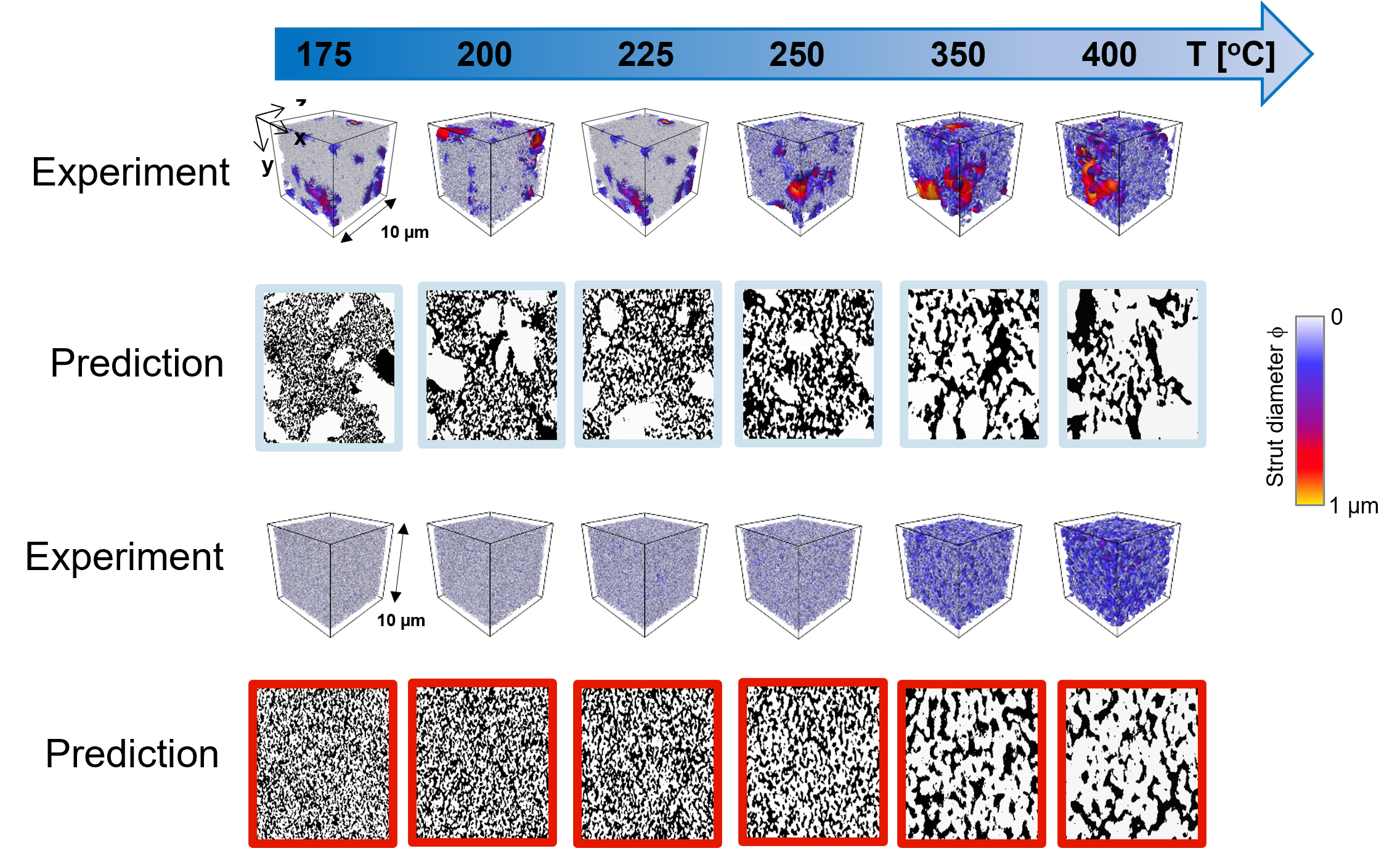

Further, the recent development in deep learning provides exciting possibilities towards synthetic image generation enabling the possibility to predict material properties for unseen conditions. In particular the prediction of material properties from a given microstructure and its reverse engineering displays an essential ingredient for accelerated material design.

The Materials Center Forschung GmbH, developed (within the COMET framework K2 Center IC-MPPE, P. No. 886385, P. No. P2.22 ECOSolder and FFG-projects: NanoPore, P. No. 883905, ProQualiCu, P. No. 853467 ) a comprehensive methodology suitable to uncover the underlying processing-structure-property relationship in porous materials. The team utilizes a multi-method machine learning approach incorporating tomographic image data acquisition, segmentation, microstructure feature extraction, feature importance analysis and synthetic microstructure reconstruction.

The presented findings highlight not only the importance of synthetic image generation and of accurately retrieving a set of microstructural features with statistical confidence for accelerated material design but also scrutinizing the features physical meaning in context to the material property. The presented methodology provides an essential step for the prediction of material properties, of unseen conditions, for porous materials.

A link to the manuscript can be found here: Analyzing microstructure relationships in porous copper using a multi-method machine learning-based approach | Communications Materials (nature.com)

Follow the Topic

-

Communications Materials

A selective open access journal from Nature Portfolio publishing high-quality research, reviews and commentary in all areas of materials science.

Related Collections

With Collections, you can get published faster and increase your visibility.

Advanced characterizations of high-entropy materials

Publishing Model: Open Access

Deadline: Mar 31, 2026

Multifunctional hydrogels

Publishing Model: Open Access

Deadline: Feb 28, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in