Step-up thermal aging for critical temperature recognition

Published in Materials and Mechanical Engineering

Reactor pressure vessels (RPVs) are expected to operate in severe conditions with a lifespan up to 60 or even 80 yearswith economic viability and sound safety, while the bainitic steel used in RPVs deteriorates during thermal service because of the thermal aging-induced embrittlement. To achieve an equivalent aging state in limited time, accelerated thermal aging at an elevated constant temperature has been widely adopted to deduce and predict thermal aging behavior in long service time. However, the rates of kinetic processes such as volume diffusion and order-disorder transitions can be different at various temperatures, which influence the validity of accelerated thermal aging test.

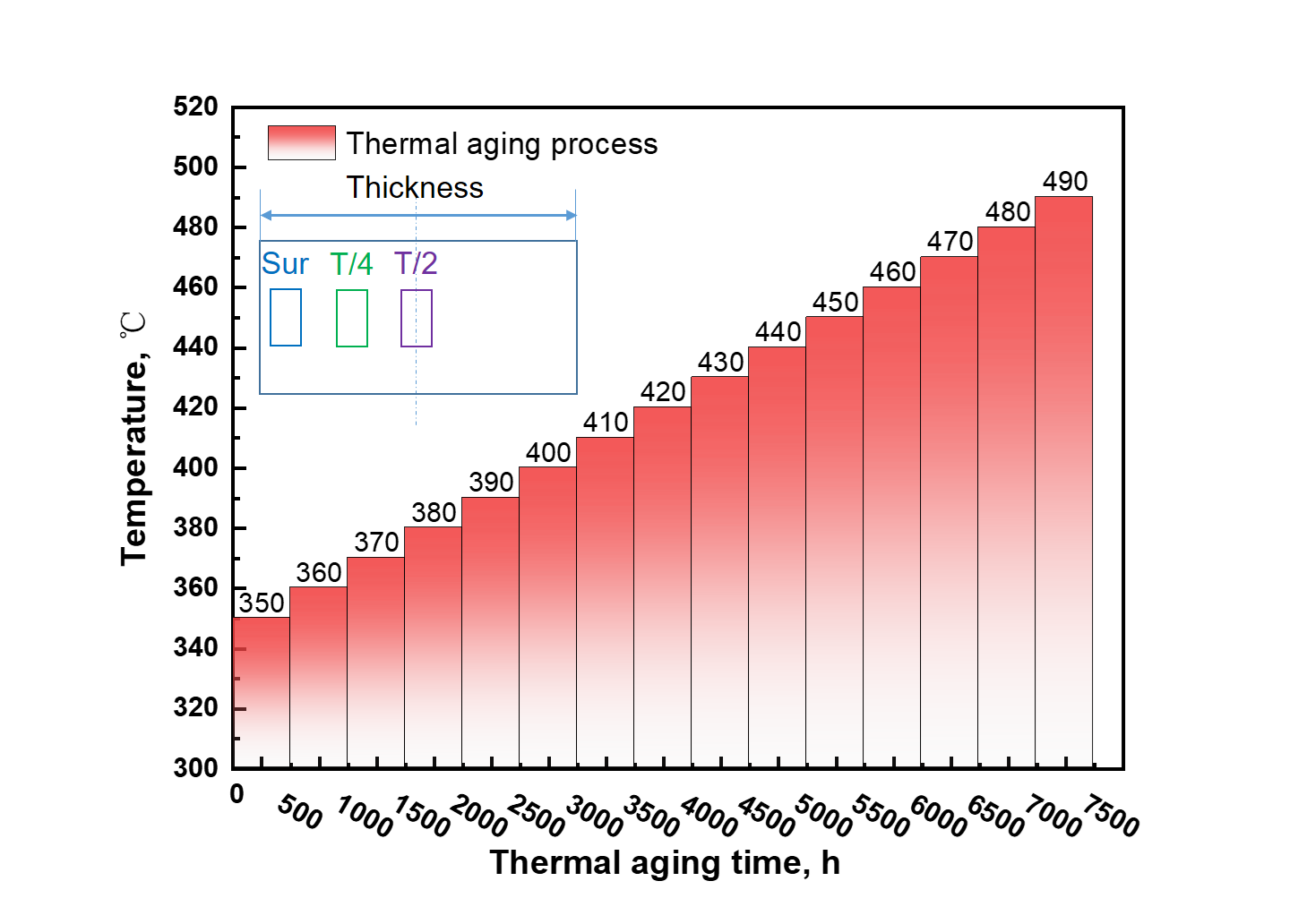

Guided by an assumption we made that the thermal aging-induced material degradation is under a temperature and time-dependent cumulative effect of microstructural evolution, we proposed a thermal aging restructuring scheme by step-up aging the steel from 350°C (design temperature) to 490°C with a total duration of 7500 hours, as shown in Fig. 1. Samples in varied thickness of the steel were characterized in terms of carbides evolution and Charpy impact toughness at 20°C.

Fig. 1 Thermal aging restructuring scheme for material from different depths of RPV

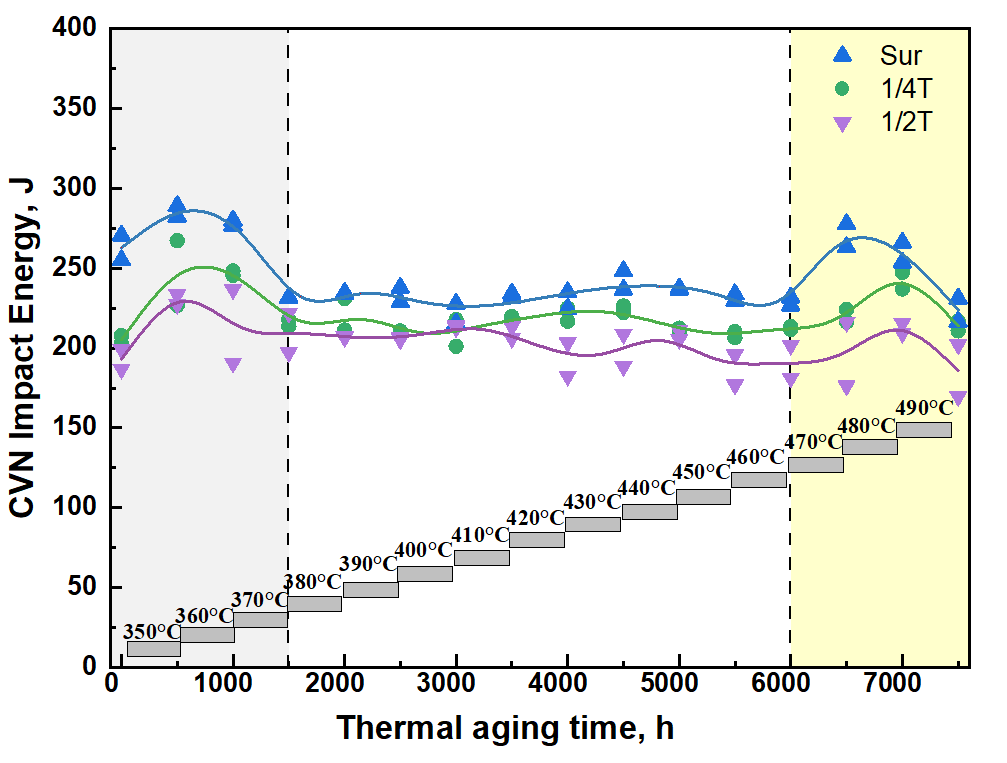

The evolution of impact energy versus aging time showed a bathtub curve with two distinct peaks across three regions in Fig. 2: the quasi-equilibrium zone in light grey, the stable zone in white, and the mutation zone in light yellow. The mutation in suddenly rising impact energy values indicates that 470°C is probably the temperature threshold that transforms the aging mechanism, which is the first time a verified temperature range for accelerated thermal aging of low alloy steel has been established based on testing. The findings reveal that, to ensure a consistent thermal aging mechanism with actual service circumstance, it is necessary to ensure the accelerated testing temperature is below 470°C.

Fig. 2 Bathtub curve of CVN impact energy as a function of thermal aging states for material sample featuring three depths.

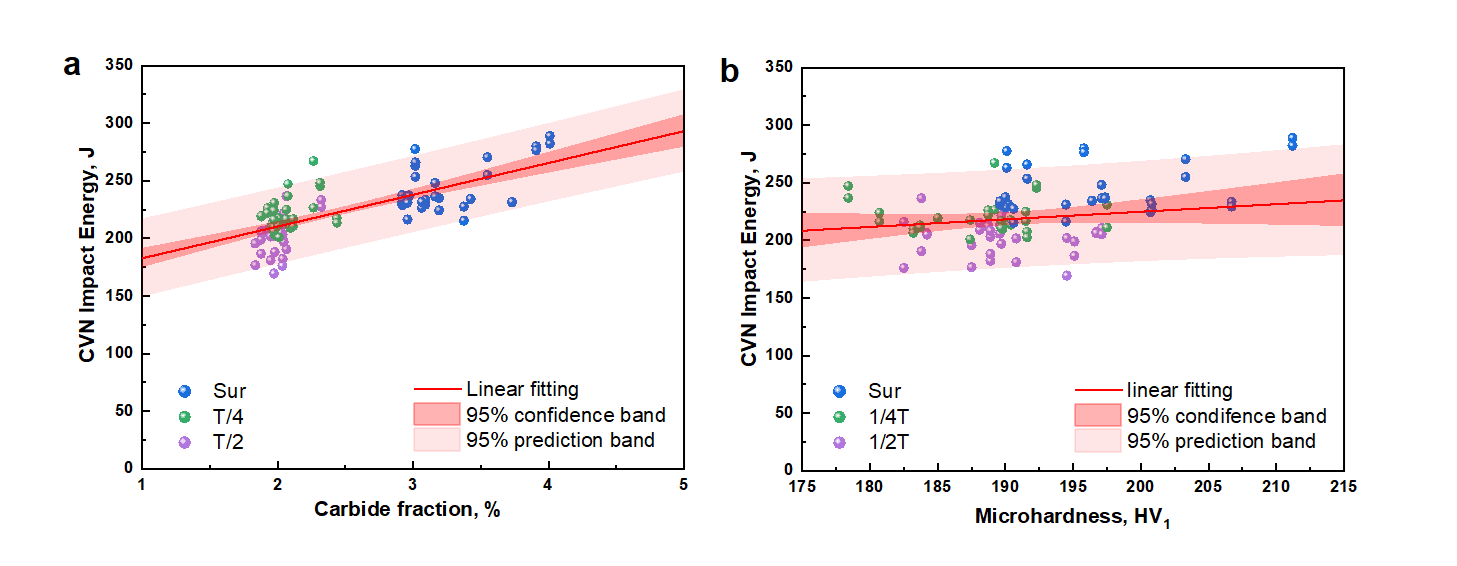

Carbides, as the primary reinforcing phase in low-alloy steels, has a significant impact on material properties. The carbide content and size were then statistically analyzed and carbide experienced partial coarsening and dissolution during aging, while the carbide fraction other than micro-hardness was found linearly correlated with the impact energy, as shown in Fig. 3.

Fig. 3 Correlation among impact energy, carbide fraction and micro-hardness.

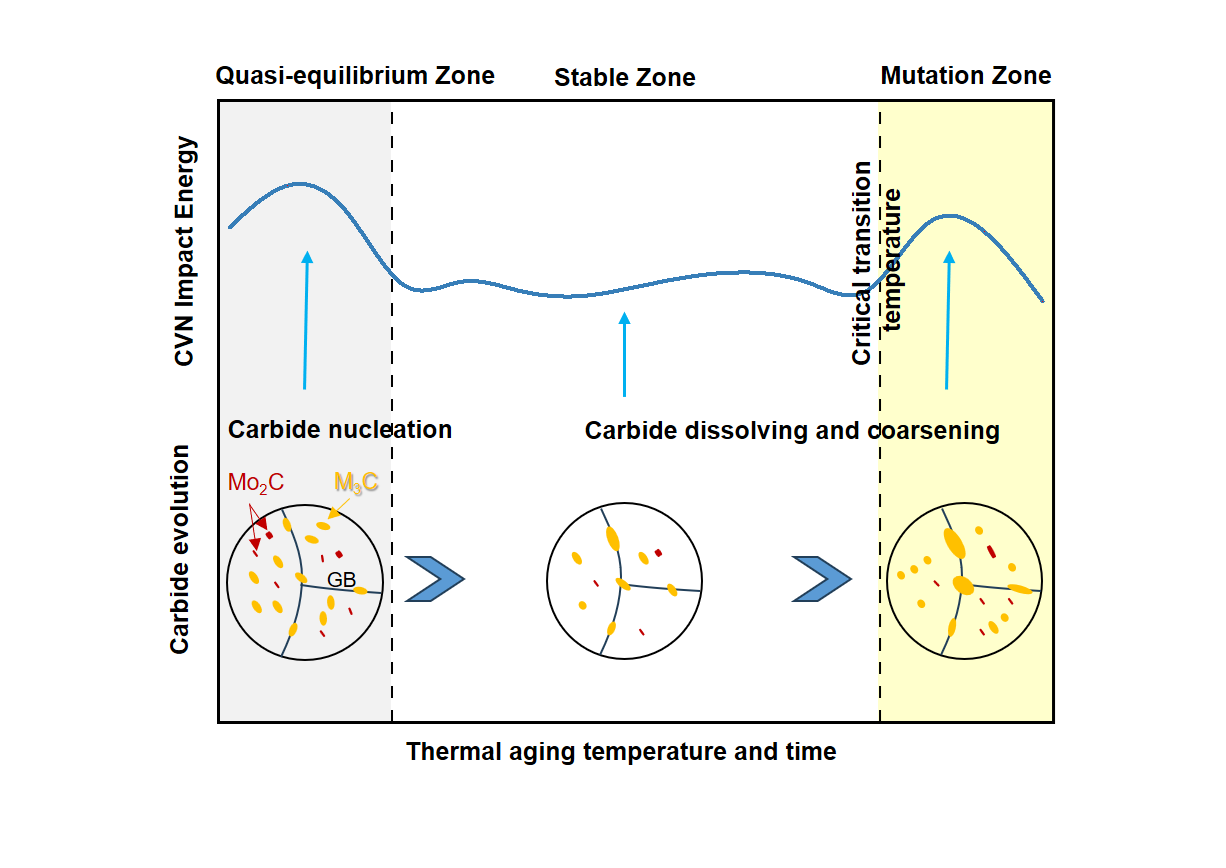

The CVN impact energy in different aging conditions can be related to the carbide evolution: The first stage is the nucleation of new carbides in quasi-equilibrium zone, which induces higher impact energy; the second stage is the carbide dissolving and coarsening process in Fig. 4. Furthermore, the impact fracture mechanism is controlled by the competition between large and small carbides, where the impact energy is increased as a result of small carbide diffusion within the grain, while it is decreased by those coarsened large carbides.

Fig. 4 The mechanistic diagram of the relationship between CVN impact energy and carbide evolution after aging.

These works could enrich the current limited data regarding thermal-aged properties of low alloy steels, which is essential for the design of nuclear power plants with extended lifetimes.

The research was conducted by East China University of Science & Technology, Shanghai, China. The paper titled “Evolution of carbides and Charpy toughness in a low alloy bainitic steel during step-up aging process” was published in October, 2024.

The full paper can be accessed via https://rdcu.be/dXCVw

Follow the Topic

-

npj Materials Degradation

This journal considers basic and applied research that explores all aspects of the degradation of metallic and non-metallic materials. The journal broadly defines ‘materials degradation’ as a reduction in the ability of a material to perform its task in-service as a result of environmental exposure.

Related Collections

With Collections, you can get published faster and increase your visibility.

Decoding Degradation: Advances in the Materials Genome

Publishing Model: Open Access

Deadline: Mar 20, 2026

Environmentally Assisted Fracture

Publishing Model: Open Access

Deadline: Mar 13, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in