Superelastic and Washable Micro/Nanofibrous Sponges Based on Biomimetic Helical Fibers for Efficient Thermal Insulation

Published in Materials

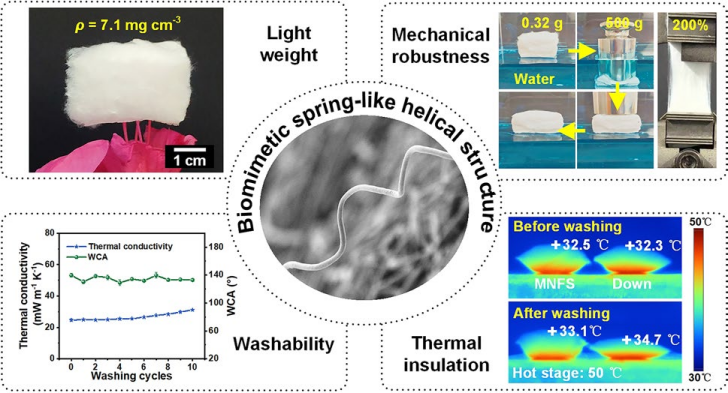

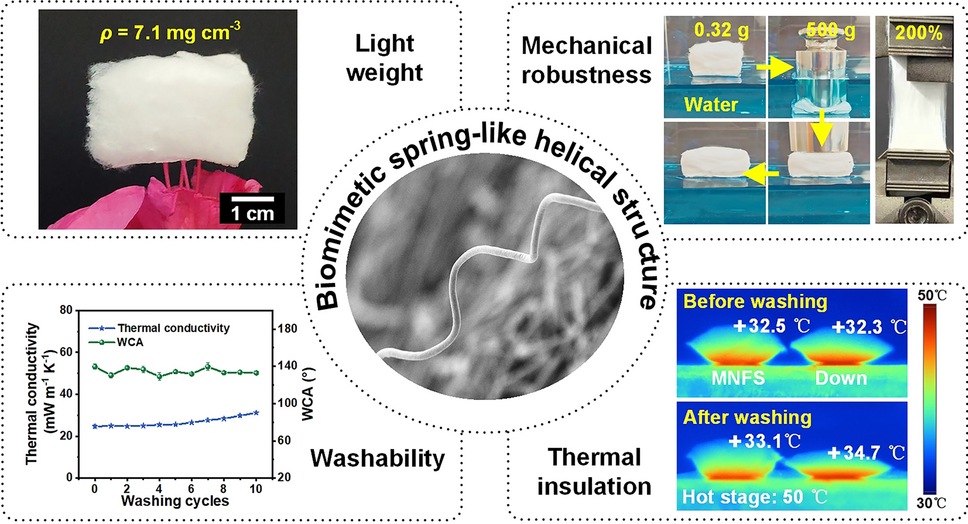

A research team led by Professor Fei Wang from Donghua University has reported a pioneering study in Nano-Micro Letters on the fabrication of superelastic and washable micro/nanofibrous sponges (MNFS) with exceptional thermal insulation. Inspired by the coiled architecture of cucumber tendrils, this work introduces a biomimetic design strategy that enables scalable production of spring-like helical fibers with hierarchical porosity and outstanding mechanical and thermal performance.

Why It Matters

Extreme cold poses serious challenges to human thermoregulation, yet existing fibrous insulating materials often suffer from poor elasticity, weak durability, and structural collapse after washing. The newly developed MNFS bridges these limitations by combining mechanical robustness, ultralight architecture, and stable heat retention, offering promising potential for wearable protection, aerospace, and building insulation.

Key Innovations

- Biomimetic Design: Natural tendril-inspired helical fibers form a 3D entangled network, providing elasticity and structural integrity.

- Direct Electrospinning Assembly: Controlled solution conductivity and solvent volatility enable multijet ejection and helical fiber formation in one step, achieving scalable fabrication.

- Lightweight and Elastic Structure: The sponge features ultralow density (7.1 mg cm-3), high porosity (99.6%), and superelasticity (200% strain) with full recovery after 1000 cycles.

- Exceptional Thermal and Washing Durability: With thermal conductivity of 24.85 mW m-1K-1, the MNFS rivals dry air and retains performance after 60 washing cycles and exposure to −196 °C.

Mechanistic Insights

The spring-like configuration allows fibers to stretch and recoil, dissipating stress through reversible deformation and entanglement. Multiscale pores within and between fibers suppress both solid and gas-phase heat conduction, resulting in superior insulation efficiency and mechanical resilience.

Future Prospects

This study provides a scalable platform for developing multifunctional fibrous sponges that integrate elasticity, insulation, and environmental stability. Beyond personal protection, the concept holds great promise for aerospace structures, energy-efficient architecture, and adaptive wearable systems. By merging biomimetic principles with electrospinning engineering, Professor Wang’s team presents a new paradigm for lightweight, sustainable, and high-performance thermal insulation materials.

Follow the Topic

-

Nano-Micro Letters

Nano-Micro Letters is a peer-reviewed, international, interdisciplinary and open-access journal that focus on science, experiments, engineering, technologies and applications of nano- or microscale structure and system in physics, chemistry, biology, material science, and pharmacy.

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in