Taming Buckling: Turning Instability into Precision in MEMS Accelerometers

Published in Electrical & Electronic Engineering, Physics, and Mechanical Engineering

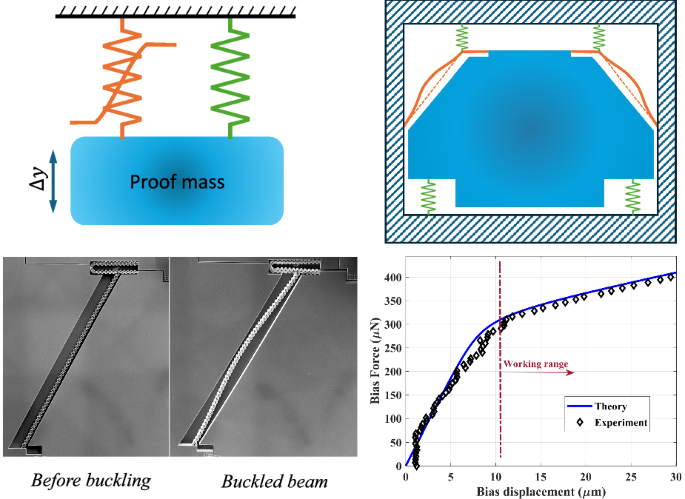

The development of high-performance micromachined accelerometers has long been driven by a central challenge: combining extreme sensitivity with a wide dynamic range. Over the past decade, remarkable progress has been made. Curved-beam and anti-spring structures pioneered by Middlemiss et al. and Tang et al. demonstrated astonishing precision, detecting Earth tides and a couple of nano-g accelerations that once seemed unachievable. Yet, these designs came at a cost. They required large proof masses, significant bias displacements (i.e., the initial displacement of the proof mass due to large offset accelerations, such as the Earth's gravitational acceleration), and intricate pre-curved geometries that made them difficult to fabricate and control. The very mechanisms that gave them high sensitivity also limited their range and stability.

When we began this project, our goal was to rethink that trade-off. We asked: Could a nonlinear mechanism enhance sensitivity without relying on heavy proof masses or large snap-through motion?

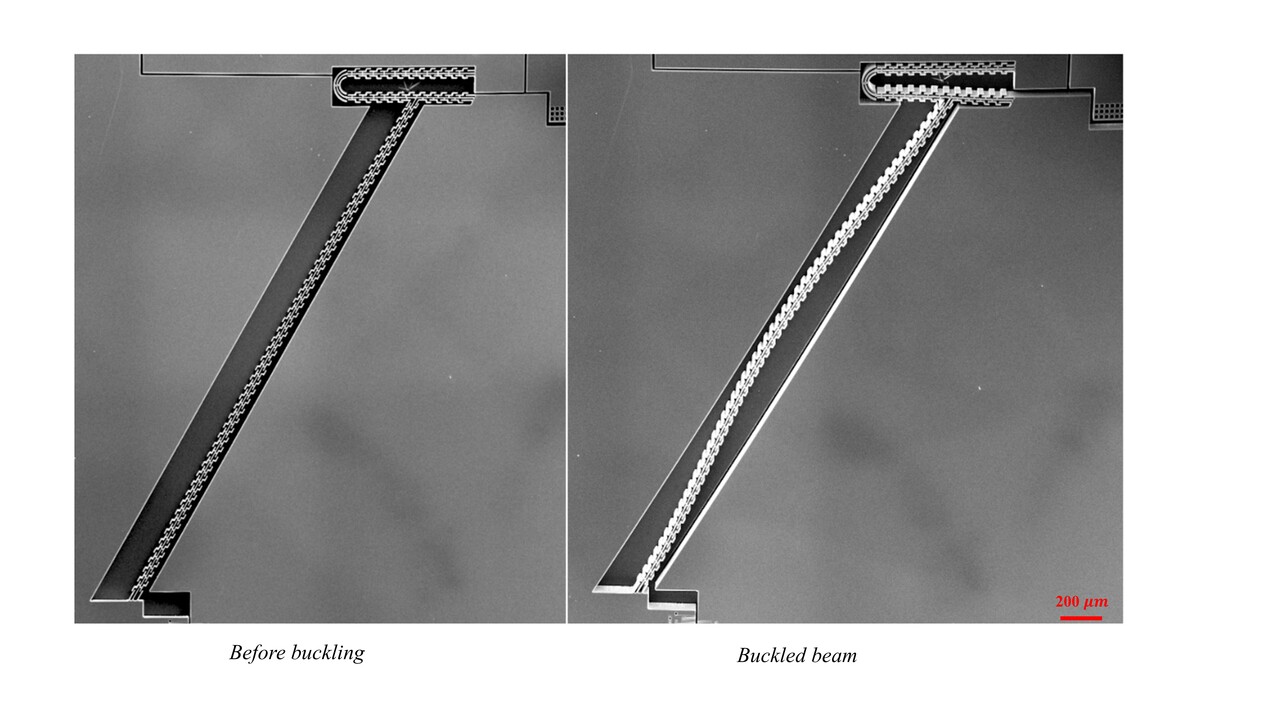

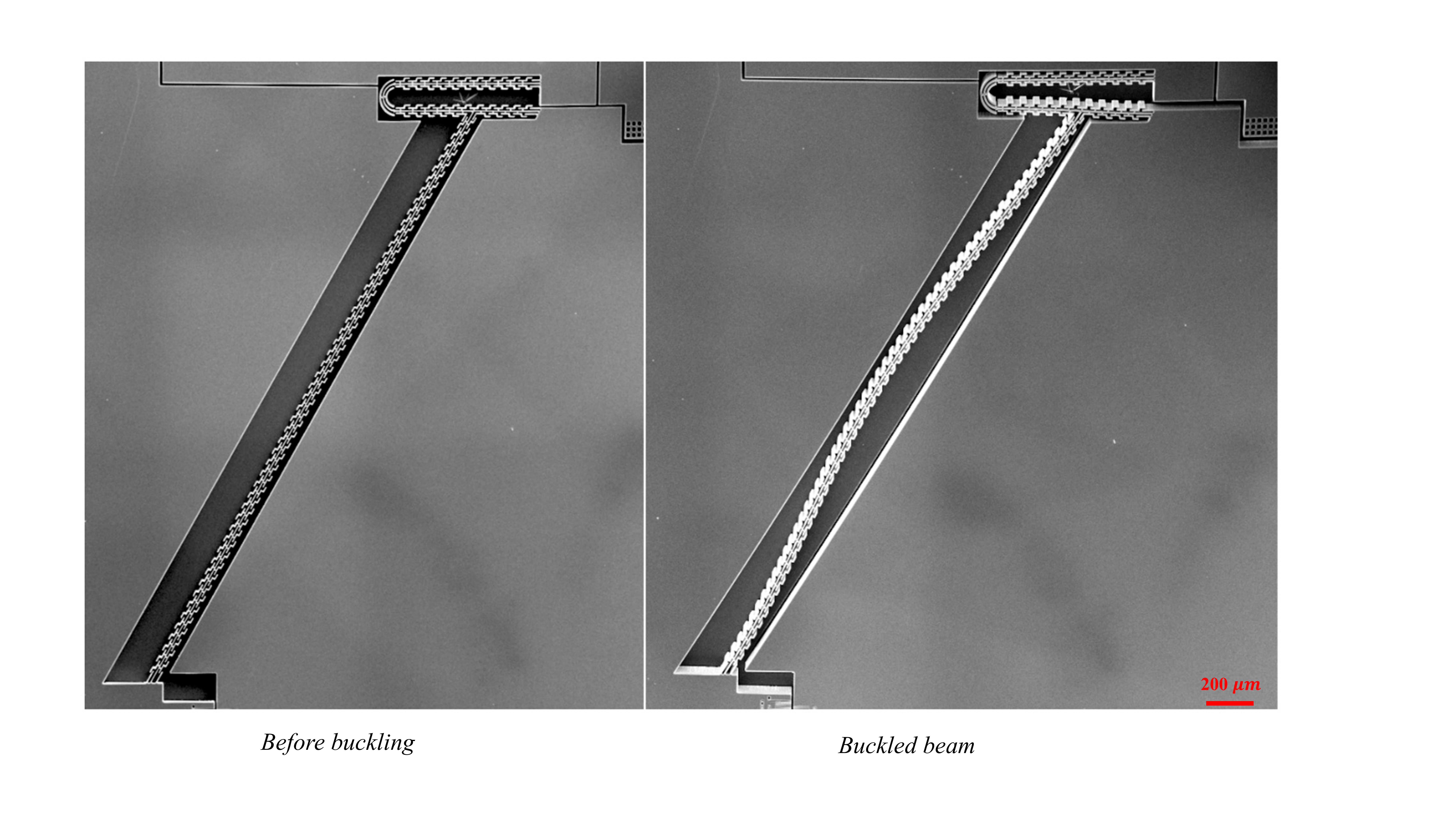

The answer to these questions is given in our Nature Microsystems & Nanoengineering article, where we explore buckling, a phenomenon typically seen as a failure mode. But what if we could control the buckling speed and its direction? By introducing an inclined beam that buckles under a precisely tuned load, and applying an eccentric force through a micro-arm, we discovered a way to guide the instability rather than avoid it. Once the beam buckles, the system naturally transitions into a softer, more sensitive state without losing stability or requiring large displacements.

We modeled this behavior analytically, simulated it using finite-element analysis, and then fabricated a silicon prototype with an integrated on-chip optical interferometer to capture its motion. The results exceeded our expectations: an 11-fold reduction in bias force and a 100-fold smaller bias displacement compared to traditional anti-spring designs, yet with improved linearity range. Seeing the proofmass smoothly settle into its softened regime under the microscope was a defining moment; the structure didn’t fail, it adapted (See video below of the device transition into the softening regime).

Even more exciting, our model revealed different design potential. By simply tuning the inclined beam’s angle and dimensions, we found that the same design can have different functionality, achieving ultra-high sensitivity without changing the proofmass weight. This geometric control opens an entirely new design space for MEMS sensors, where stiffness, sensitivity, and dynamic range can be engineered through structure alone.

This study shows that embracing controlled nonlinearity can transform how we design micro-scale devices. With its compact footprint and scalable fabrication, our nonlinear buckling mechanism could power the next generation of MEMS accelerometers for gravimetry, seismic sensing, and space exploration, where precision and resilience must coexist.

Follow the Topic

-

Microsystems & Nanoengineering

This journal, with a target for a high-end journal for years to come, seeks to promote research on all aspects of microsystems and nanoengineering from fundamental to applied research.

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in