What Historical On-site Sampling and Industrial Hygiene Reports at U. S. Steel tell us about Asbestos Exposures in the Steel Industry (1972-2006)

Published in Sustainability

In order to address the lack of studies and publicly available data from on-site steel mill operations, our firm evaluated nearly 2,000 pages of internal reports which described 495 personal asbestos air monitoring samples collected between 1972-2006 at United States Steel Corporation. These previously nonpublic airborne asbestos data and industrial hygiene records from 16 United States Steel Corporation (U. S. Steel) facilities were analyzed. This is the most robust collection of industrial hygiene data regarding the steelmaking industry of which we are aware. Thus, it should be insightful approximating exposures at most steel companies – in part because steel has been manufactured in essentially the same way across the entire industry. Unions and trade associations have played a role in influencing these companies to benchmark their work conditions with one another.

The goals of this study were to provide insight into where asbestos-containing materials were historically used within steel mills and then characterize the airborne fiber concentration to determine trends across time periods, facilities, departments, and job titles. It is our hope that our analysis encourages other large firms to publish/analyze their industrial hygiene data to help characterize historical occupational exposures.

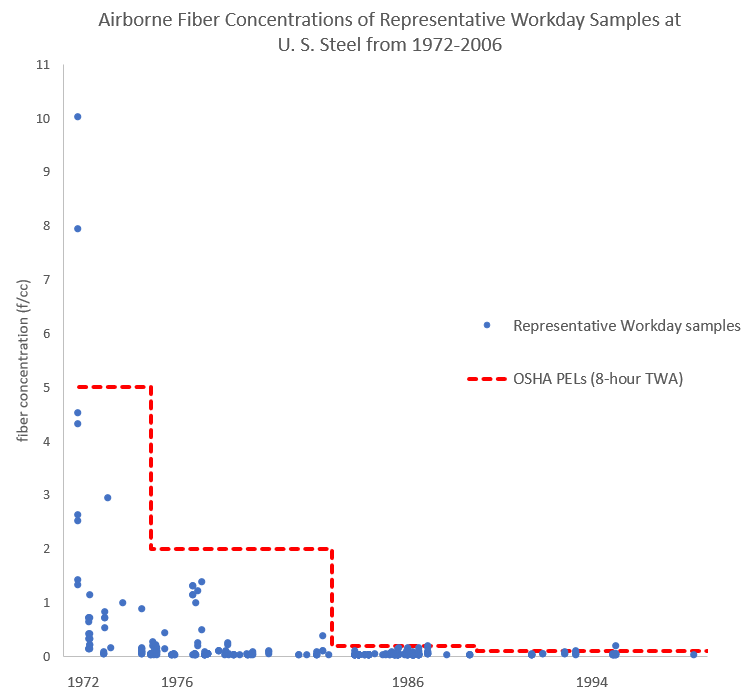

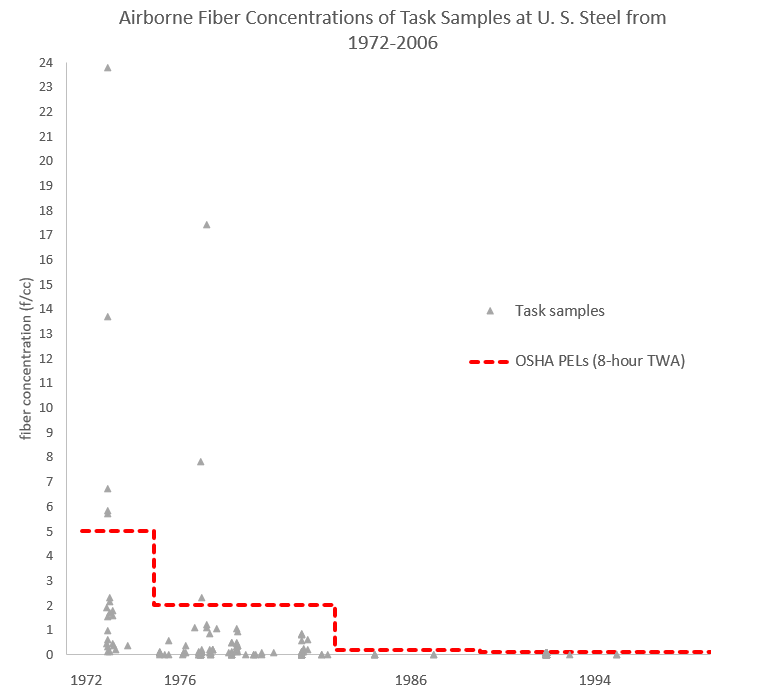

Figures 1 and 2 show that asbestos exposures in the steel industry have been decreasing over time and, in general, were below contemporaneous OSHA PELs standards. Samples were broken up into two categories: representative workday samples (those with sampling times greater than 180 minutes) and task samples (those with sampling times less than 180 minutes). Additionally, when the industrial hygiene report included a calculated an 8-hour TWA based on the sample, these samples were considered representative workday samples. As a conservative measure, samples from the IH reports with unknown sampling times were assumed to be representative workday samples as well. These two classifications were made because the representative workday samples are believed to be more predictive of what 8-hour time weighted average (TWA) exposures might be and therefore are more reasonable to compare to the OSHA permissible exposure limits (PELs).

The airborne concentrations presented in Figures 1 and 2 are likely to overestimate the actual exposures due to the use of phase-contrast microscopy (PCM) to determine the concentrations, the use of respirators (which was required for many U. S. Steel employees) not being statistically accounted for, and because a disproportionate number of the samples consist of work tasks that were suspected of having significant asbestos exposures (by either the industrial hygienist, OSHA, or the labor union).

Asbestos has impressive thermal properties and, as such, many of the applications of asbestos were in equipment that would be exposed to extreme temperatures. At temperatures of 930°C (~1700°F) or greater, asbestos fibers react and form silicate, a non-toxic substance. Thus, much, if not all, of the asbestos used in brake pads, hot tops, refractory brick, or insulation/gaskets close to furnaces were converted to olivine, a non-hazardous breakdown product of asbestos.

PCM sampling detects all airborne fibers (greater than 5 microns and with an aspect ratio of at least 3:1). PCM sampling does not distinguish between cotton fibers, fiberglass (a common asbestos substitute), olivine, or other others that meet the geometric definition of a fiber. Some samples that had high concentrations of fibers by PCM sampling were reanalyzed using TEM and it was determined that they contained no asbestos fibers.

The historical use of asbestos was limited to only a few applications in steel mills; many of which contained encapsulated asbestos fibers. Those limited uses were replaced by non-asbestos containing materials as they became available. The term encapsulated refers to when the fibers, in this case asbestos, are bound in resin, paper, glue or other media. It is unsurprising that airborne asbestos concentrations associated with encapsulated materials were low, as this process of binding the media together makes it almost impossible for fibers to be released into the air without significant manipulation.

In all the applications of asbestos in the United States, the composition was typically (roughly 95% of the time) chrysotile asbestos. Chrysotile is a form of serpentine asbestos and is significantly less potent for causing mesothelioma and lung cancer and less toxic than the other type of asbestos, the amphiboles. The chrysotile fibers have a half-life ranging from days to weeks at most, making it unlikely to cause the long-term health problems that can be experienced from amphibole fibers. Some experts predict that chrysotile asbestos has no potency for mesothelioma below a threshold cumulative exposure of hundreds of f/cc-years, which, based on the sample concentrations analyzed in this paper, are not likely feasible for steel mills employees.

In conclusion, the results of the study show that most working tasks performed in steel mills between 1972 and 2006 produced asbestos exposures well below OSHA regulations. This is, in part, because the vast majority of procedures in steel mills do not require the use of free asbestos. Generally speaking, the industrial hygienists at U. S. Steel who collected these samples concurrently implemented work-practice changes, engineering controls, and the use of respirators to minimize exposure until non-asbestos containing alternative materials became available. The effect of these practices can be seen as there were significant decreases in fiber across the first two time periods (1972-1975 and 1976-1985) until fiber concentrations began to level off (Figure 1 and 2). Out of the 11 PEL exceeding instances, which represented around 2% of all samples collected, 10 of them occurred prior to 1978 (Figure 1 and 2), only one of them had a sampling time greater than 180 minutes (the remaining two representative workday samples had unknown sampling times), and many of these were collected when the employee was using a respirator.

If you have any questions on this paper or Paustenbach and Associates Scientific Consulting Firm, please contact Michael Stevens for more information at mstevens@paustenbachandassociates.com or (708)466-3614.

Follow the Topic

-

Journal of Exposure Science & Environmental Epidemiology

This journal aims to be the premier and authoritative source of information on advances in exposure science for professionals in a wide range of environmental and public health disciplines.

What are SDG Topics?

An introduction to Sustainable Development Goals (SDGs) Topics and their role in highlighting sustainable development research.

Continue reading announcement

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in