A simple production of nanoparticle-decorated nanofibres

Published in Chemistry

Here, we report a simple and inexpensive way of producing nanofibres incorporating nanoparticles, in a process that gives us high yields.

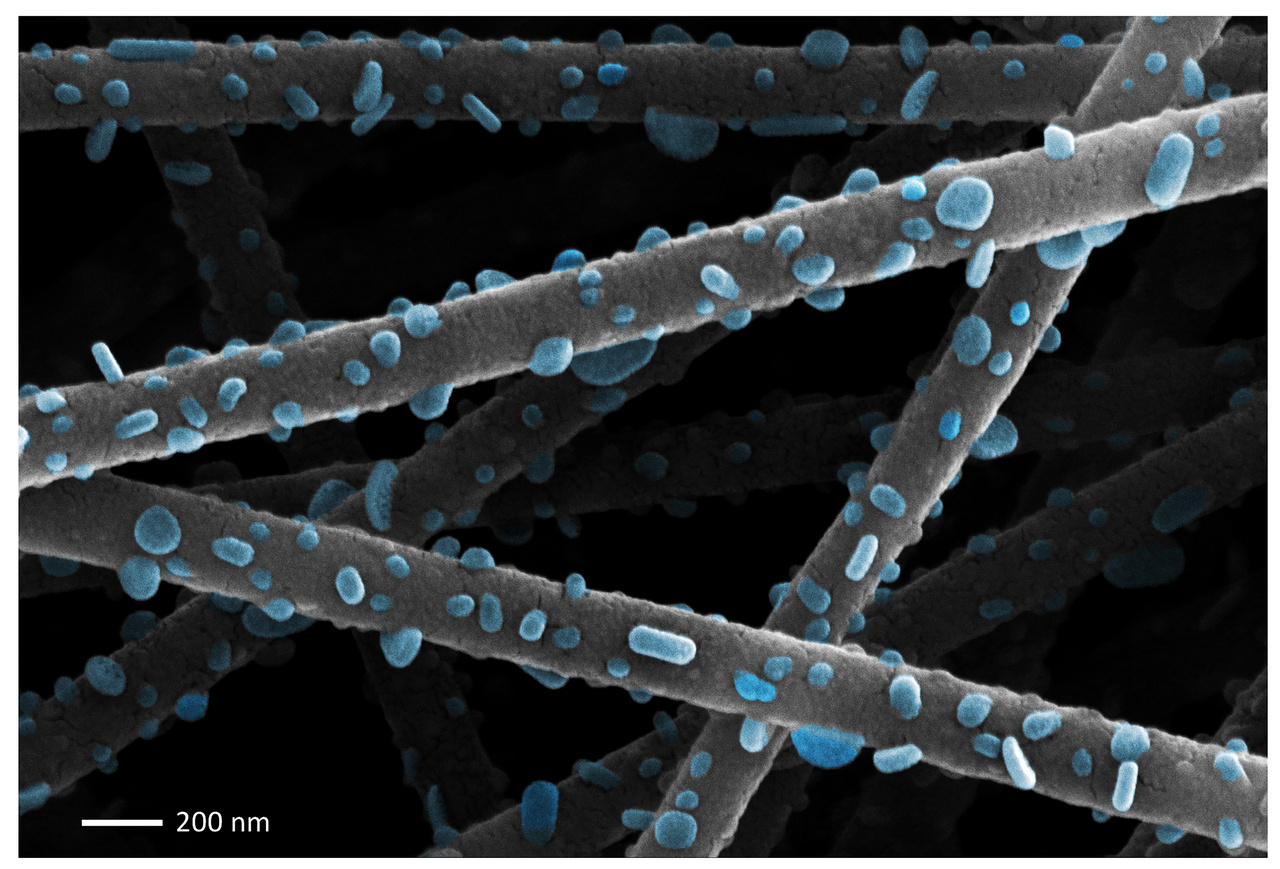

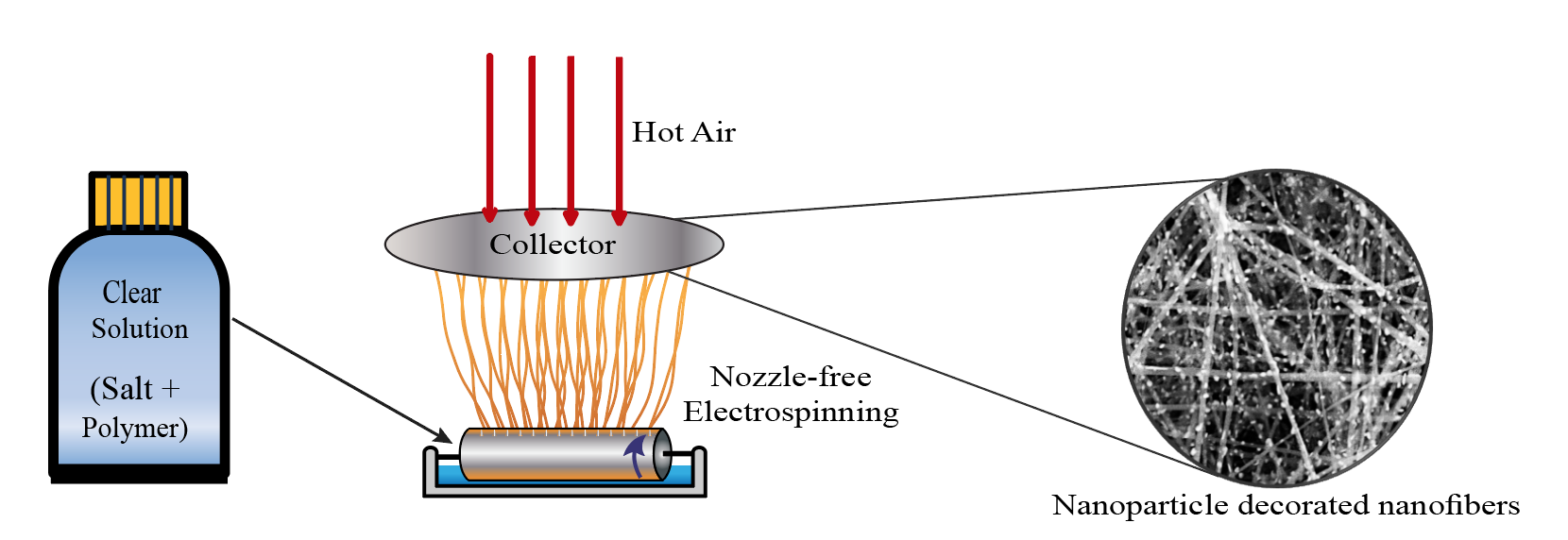

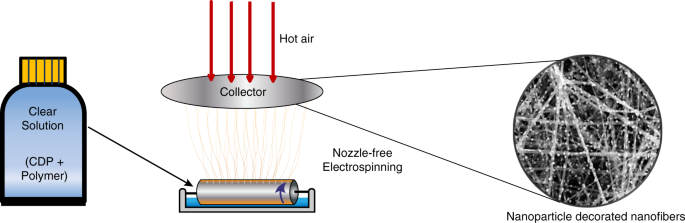

We have identified the use of nozzle-free electrospinning, a method that applies high voltage on a rotating electrode as a way to spontaneously produce nanoparticles on the surface of nanofibres. An electrode is immersed in a clear solution that contains an electrolyte salt and a carrier polymer (Figure 1). An applied voltage of more than 45,000V charges the liquid solution, and generates repulsive electrostatic forces that overcome the surface tension of the liquid. As a result, several liquid jets are dispensed from the surface. The applied electric field induces electrical instabilities that cause the jets to elongate and bend. The drawn polymeric threads are directed to a rotating collector, which is heated to 120 °C. As the fibres solidify, the electrolyte salts crystallise and form nanoparticles on the surface of the nanofibres. This results in a structure that is similar to a pretzel stick. This process is easily scalable, and gives high yields compared with other nanofabrication techniques.

Figure 1.Schematic overview of the nanofabrication process of nanoparticle-decorated nanofibres from a clear solution by nozzle-free electrospinning.

Our process could potentially speed up the commercial development of devices, materials and technologies that exploit the physical properties of nanoparticles and nanofibres, which are thousands of times thinner than a human hair. The particles’ small size means they behave differently compared with conventional materials, and their unusual properties are inspiring research towards new applications.

By incorporating nanoparticles on the surface of nanofibres, they offer a high contact area between the catalyst, the electrolyte and the oxygen in the air, making the device more efficient. Due to the nanofibrous structure, the interface between the electrode and electrolyte is also enhanced. We have fabricated fuel cell electrodes with this process, which outperform the state-of-the-art commercial fuel cells of this type.

The study, published in Nature Communications, can be downloaded from here: link

Follow the Topic

-

Nature Communications

An open access, multidisciplinary journal dedicated to publishing high-quality research in all areas of the biological, health, physical, chemical and Earth sciences.

Related Collections

With Collections, you can get published faster and increase your visibility.

Women's Health

Publishing Model: Hybrid

Deadline: Ongoing

Advances in neurodegenerative diseases

Publishing Model: Hybrid

Deadline: Mar 24, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in