ABAA! – Alternating-Bias Assisted Annealing of Amorphous Oxide Tunnel Junctions

Published in Materials, Physics, and Computational Sciences

Quantum computers capable of addressing real-world problems will require hundreds, if not thousands or millions, of high performing qubits. To accomplish this we need to overcome challenges associated with the delicate nature of devices for quantum applications. Specifically, this requires exquisite control over the materials, design, and environment of our qubits. From a computing standpoint, we also need precise addressing and control of individual and multiple qubits.

Rigetti’s continued leadership in designing and manufacturing high performance superconducting quantum processors is, in a large part, due to our dedicated fabrication, assembly and test infrastructure. Rigetti’s Fab-1, located in Fremont, California, is the industry’s first dedicated and integrated quantum device manufacturing facility. Fab-1 includes state-of-the-art lithography in a more than 6000 ft2 cleanroom tailored to the subtleties of building superconducting quantum circuits.

In particular, superconducting circuits rely on nebulously-thin (~ 10 atoms) amorphous insulation layers that allow electrons to penetrate through the insulator, from one electrode to the other. This process, referred to as “tunneling through a junction,” causes the circuits to ring at discrete frequencies, enabling us to design and build each qubit as a tiny radio station with its own frequency band. While the reproducibility and energy loss in these junctions has been notoriously difficult to control, the simplicity, scalability and ease of fabrication of these devices makes them one of the best platforms for building quantum computers. Finding a solution to the junction reproducibility problem has been a long-standing goal in the field.

At Rigetti, we recently discovered and implemented a novel technique, i.e.”Alternating-Bias Assisted Annealing” (ABAA), to coax, nudge, and re-order the atoms in these delicate tunnel junctions to precisely target specific qubit frequencies. In collaboration with contacts forged through the Fermilab Superconducting Quantum Materials and Systems Center (Ames National Laboratory and Iowa State University), high-resolution transmission electron microscopy studies were conducted on these samples. These studies showed that the atoms inside the junctions are actually being mixed and homogenized in the process, thereby allowing us to tweak the material at the nano-scale level in order to achieve much more precise frequency allocations relative to the as-fabricated devices.

This ability to controllably tune qubits prior to a chip being packaged is essential for large-scale QPU production. This improves the addressability of the qubits, speeds up interactions, and improves the scalability of the technology. We believe that this discovery may bea turning point in the development of superconducting quantum computing, similar to the CMOS revolution for silicon, because ABAA makes junction resistance targeting with high precision possible. This brings us closer to realizing the goal of utilizing nature’s quantum toolbox by engineering the materials for optimal performance.

The specific material that we have applied ABAA to, i.e. aluminum-oxide, forms the backbone of nearly all superconducting quantum circuits due to aluminum’s intrinsic superconductivity and tendency to form a conformal and controllable surface oxide. This oxide barrier can be so thin that the electrons tunnel right through, giving rise to the well-known “Josephson Effect.” This, in combination with the capacitance, generates the oscillations and quantized spectra that we utilize to make qubits. However, this process yields a highly disordered, amorphous structure in the oxide with various inhomogeneities and imperfections. These cause relatively large uncertainties and defects that can interfere with the frequency allocation and qubit spectra, respectively.

Unlike more complicated solutions that address this problem by heating the junction area with strong lasers or an intense electron beam, the ABAA technique is a simple and scalable process that gently mixes the atoms in the as-grown junction by applying a series of low, alternating voltages at room temperature.

ABAA dramatically reduces the instrumentation and effort required to trim the junctions. Furthermore, it gives nearly an order magnitude higher tunability range because it uses a fundamentally new and different mode of atomic mixing and allows for real-time feedback. This results in better control of the qubit frequency and has been shown to improve not only the precision of the frequency allocation, but also the absolute accuracy with respect to the target values. These two factors are key to improving the lifetimes of qubits and the ability to control and persuade them to do interesting quantum computations that are difficult using classical techniques.

Perhaps fortuitously, but understandably in hindsight, we observe that the ABAA technique appears to sweep out some of the defects and imperfections in the junction. This clears the way for a cleaner spectrum of the qubits and couplers, allowing the components to communicate with each other in the circuit with less interference. This takes a lot of the guesswork and brute force design-by-trial out of the fabrication of superconducting devices.

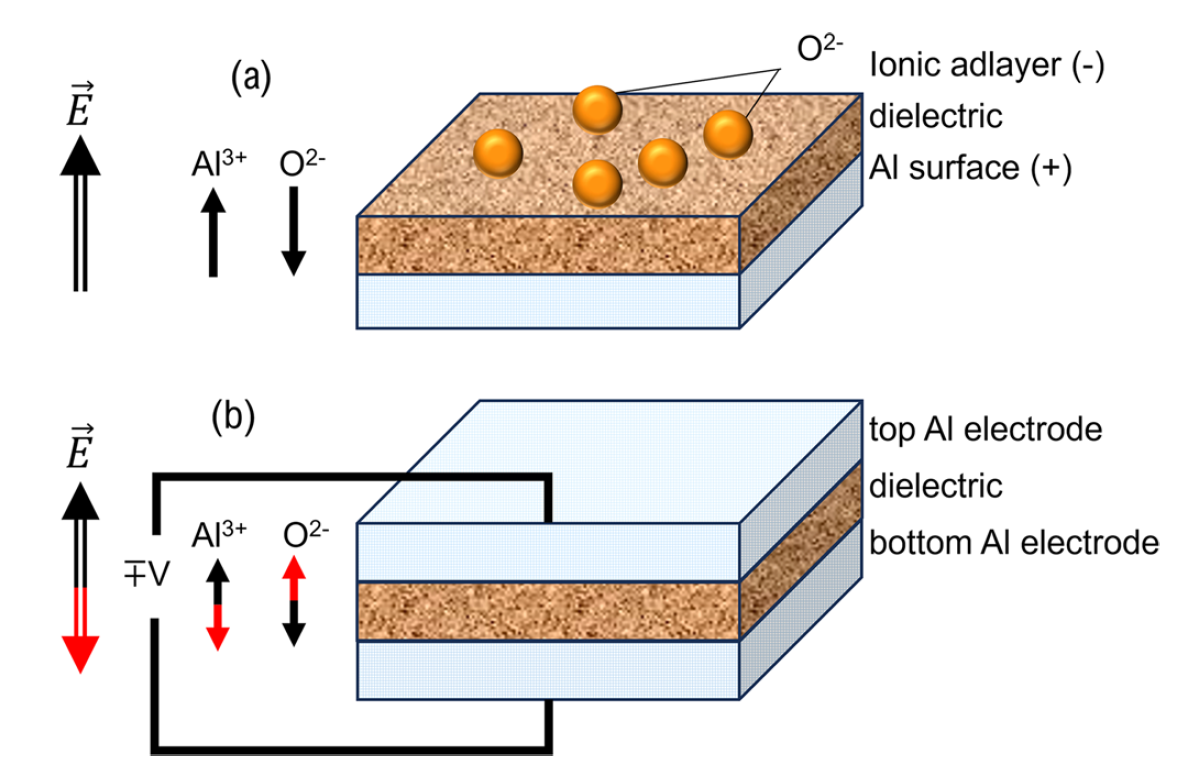

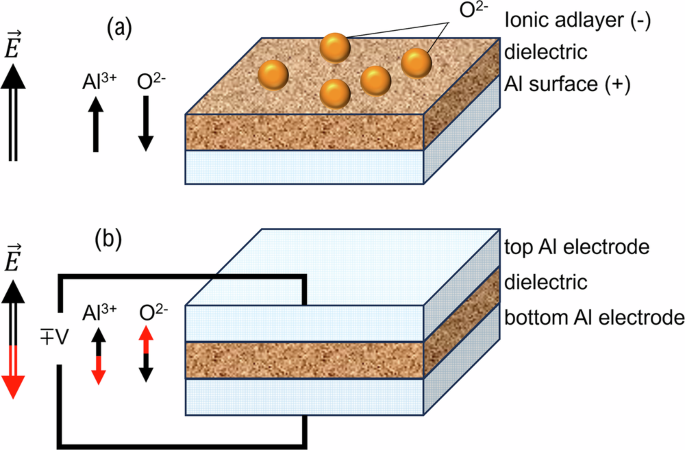

Taking a deeper dive into the mechanics of ABAA, it is instructive to review the process of how metals, including aluminum, oxidize. The accepted mechanism for this oxidation is the “Cabrera-Mott Model,” illustrated in Figure 1(a). In this model, an electric field forms at the surface as oxygen is adsorbed and dissociates. This pulls the aluminum cations up out of the bulk and pushes oxygen anions down into the vacancies left over. This process slows down as the film gets thicker and the electric field weaker, ultimately forming a continuous, amorphous aluminum-oxide layer. This layer tends to be oxide-rich at the top and aluminum-rich at the bottom, while the various atoms as well as contamination and stray charges can be trapped in meta-stable defect sites during the process.

The dynamic, driven Cabrera-Mott mechanism (i.e. ABAA) is illustrated in Figure 1(b). This process is applied to the as-grown junctions after the top aluminum electrode has been deposited over the thin aluminum-oxide layer. A low voltage, on the order of the Mott voltage, VM, is applied across the junction using a standard probe station. This can be modulated to create an alternating electric field, driving the cations and anions periodically in opposite directions. This action controllably mixes the material as the resistance is monitored in real time.

Model: Oxide growth on aluminum mechanism. The primary assumption is that

adsorbed oxygen dissociates and ionizes. This creates a voltage VMott relative to the

Al, causing a strong electric field in the thin oxide. Due to the predominantly ionicbonded

nature of these films (56%), aluminum cations and oxygen anions feel

opposite forces due to this field. They exchange places, mediated by vacancy motion.

(b) Dynamic Cabrera-Mott Effect (ABAA): The Al/AlOx/Al trilayer is effectively

mixed by applying alternating voltages onto the tunnel barrier electrodes. The

voltage is on the order of magnitude of VMott but less than the dielectric breakdown

voltage, between the two plates. This applies alternating and opposing forces on the

two species.

This effect was discovered in late 2023 by Rigetti researchers. In the tradition of rapid optimization and integration that is a hallmark of Rigetti, a fast integration of the ABAA technique into our standard wafer fabrication process was undertaken and achieved. Over 1000 separate devices have been successfully treated, allowing us to precisely target Hamiltonians (i.e. qubit frequency allocations). This has been applied to our high-qubit count chips and enables us to implement optimal interactions and gate schemes with a high level of certainty.

Furthermore, we believe that this ABAA technique is extensible to other amorphous, ionically-bonded-materials based devices and may solve many other problems and opportunities in both classical and quantum circuits.

We are excited to share that this seminal work has been published in Nature Communications Materials and will be leveraged in our high-end chip fabrication processes for Rigetti QPUs, including the Novera™ QPU, moving forward. The underlying research for this new ABAA technique was recently unveiled as the first talk at this year’s ICTP Conference in Trieste, Italy, “New Frontiers in Scaling Quantum: from Materials and Hardware to Architectures and Components.”

Cautionary Language Concerning Forward-Looking Statements

Certain statements in this communication may be considered “forward-looking statements” within the meaning of the federal securities laws, including but not limited to, expectations with respect to the Company’s business and operations, including its expectations related to the use of the ABAA technique for qubit frequency targeting resulting in improvements in chip performance and allowing for scaling to higher qubit systems with greater control over qubit performance and expectations of the ABAA technique in connection with the anticipated 84-qubit Ankaa-3 system. These forward-looking statements are based upon estimates and assumptions that, while considered reasonable by the Company and its management, are inherently uncertain. Factors that may cause actual results to differ materially from current expectations include, but are not limited to: the Company’s ability to achieve milestones, technological advancements, including with respect to its technology roadmap, help unlock quantum computing, and develop practical applications; the ability of the Company to obtain government contracts successfully and in a timely manner and the availability of government funding; the potential of quantum computing; the ability of the Company to expand its QPU sales; the success of the Company’s partnerships and collaborations; the Company’s ability to accelerate its development of multiple generations of quantum processors; the outcome of any legal proceedings that may be instituted against the Company or others; the ability to maintain relationships with customers and suppliers and attract and retain management and key employees; costs related to operating as a public company; changes in applicable laws or regulations; the possibility that the Company may be adversely affected by other economic, business, or competitive factors; the Company’s estimates of expenses and profitability; the evolution of the markets in which the Company competes; the ability of the Company to implement its strategic initiatives, expansion plans and continue to innovate its existing services; the expected use of proceeds from the Company’s past and future financings or other capital; the sufficiency of the Company’s cash resources; unfavorable conditions in the Company’s industry, the global economy or global supply chain, including financial and credit market fluctuations and uncertainty, rising inflation and interest rates, disruptions in banking systems, increased costs, international trade relations, political turmoil, natural catastrophes, warfare (such as the ongoing military conflict between Russia and Ukraine and related sanctions and the state of war between Israel and Hamas and related threat of a larger conflict), and terrorist attacks; and other risks and uncertainties set forth in the section entitled “Risk Factors” and “Cautionary Note Regarding Forward-Looking Statements” in the Company’s Annual Report on Form 10-K for the year ended December 31, 2023, the Company’s Form 10-Q for the three months ended June 30, 2024, and other documents filed by the Company from time to time with the SEC. These filings identify and address other important risks and uncertainties that could cause actual events and results to differ materially from those contained in the forward-looking statements. Forward-looking statements speak only as of the date they are made. Readers are cautioned not to put undue reliance on forward-looking statements, and the Company assumes no obligation and does not intend to update or revise these forward-looking statements other than as required by applicable law. The Company does not give any assurance that it will achieve its expectations.

Follow the Topic

-

Communications Materials

A selective open access journal from Nature Portfolio publishing high-quality research, reviews and commentary in all areas of materials science.

Ask the Editor – Space Physics, Quantum Physics, Atomic, Molecular and Chemical Physics

Got a question for the editor about Space Physics, Quantum Physics, Atomic, Molecular and Chemical Physics? Ask it here!

Continue reading announcementRelated Collections

With Collections, you can get published faster and increase your visibility.

Advanced characterizations of high-entropy materials

Publishing Model: Open Access

Deadline: Mar 31, 2026

Fundamental science and applications of silk proteins

Publishing Model: Open Access

Deadline: Mar 31, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in