Artificial fingerprints at the nanoscale as physical unclonable functions

Published in Materials

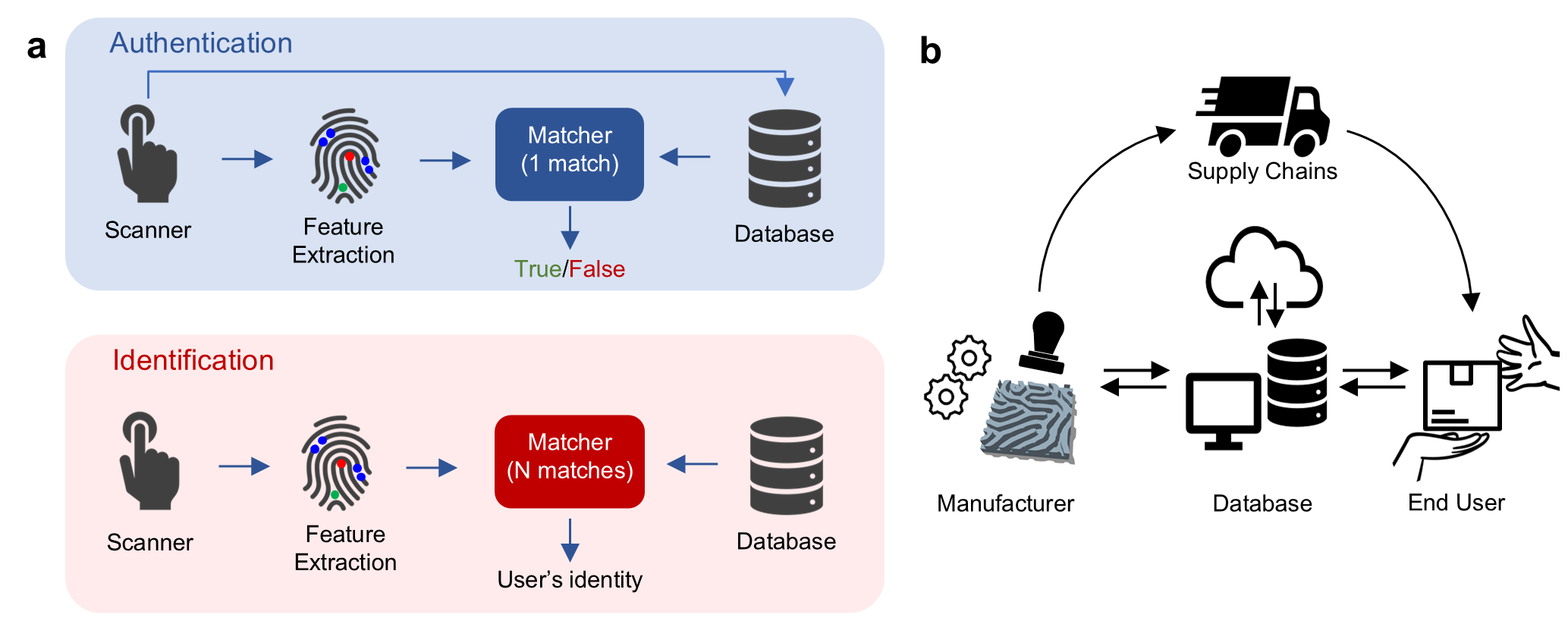

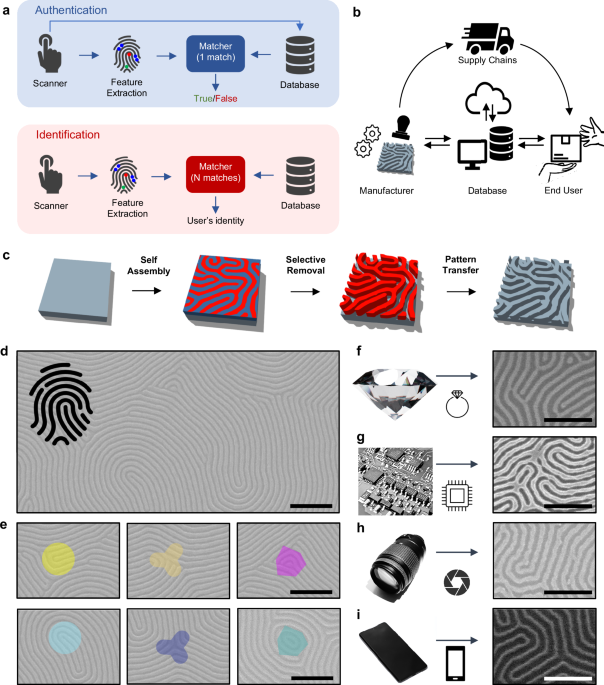

Fingerprints have always had an aura of mystery and beauty. Their uniqueness, often tied to unsolved crimes and important secrets, has captured human fascination for centuries. As early as the reign of Hammurabi in Babylon (1955-1913 a.C.), fingerprints were used as personal identifiers to authenticate commercial transactions [1]. Over the decades the use of fingerprints has remained a reliable and universal method for both authentication – i.e., matching a person’s biometric template – and identification – i.e., determining the identity of a person (Figure 1a), thus evolving into a cornerstone of modern technology. Just think about the fact that we now use our fingerprints daily to unlock smartphones and computers with a simple touch. By exploiting the same principles, artificial fingerprints can be developed for secure authentication/identification of products through the supply chain (Figure 1b), a crucial aspect for contrasting counterfeiting, that nowadays has enormous economic implications and can threaten security and health systems.

Figure 1. a. Workflow of authentication and identification processes through fingerprints. b. Authentication/identification of products through the supply chain.

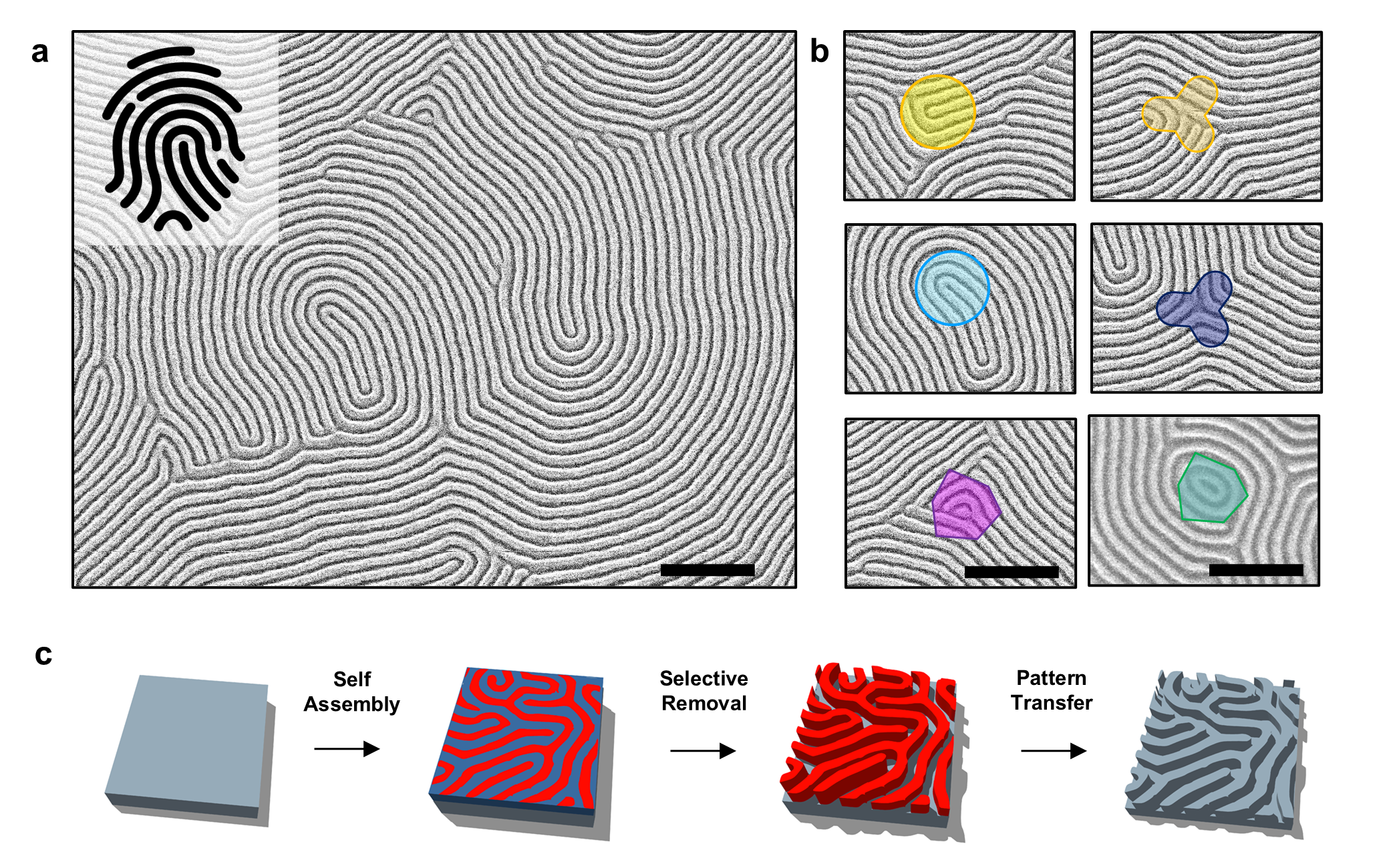

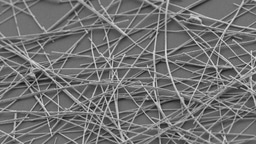

Over the past ten years our laboratories exploited self-assembling of materials to create nanostructured devices. Everyone who has seen patterns obtained through the self-organization of block copolymers (Figure 2a) said: hey, that’s a fingerprint! Indeed, these nanopatterns are characterized by ridges and valleys as human fingerprints, where ridge discontinuities, called defects, resemble minutiae features exploited in biometrics for fingerprint verification (Figure 2b). However, most of the efforts of researchers in this area have been focused on combating the inherent stochasticity of the self-assembly process of block copolymers, with the aim of using block-copolymer templating as a lithographic tool for scaling the dimension of electronic devices [2,3]. This poses several challenges since the fabrication of materials and systems at the nanoscale is hindered by unpredictable disturbances and fluctuations. Indeed, at this scale the influence of thermal and statistical fluctuation cannot be avoided, resulting in output material structures and properties that are not simply determined by known inputs [4]. However, our approach diverges from the long-standing trajectory followed to obtain technological advancements in developing nanostructured devices based on block copolymers.

Motivated by the similarities with human fingerprints and by previous works [5], we decided to explore the possibility of realizing artificial fingerprints directly engraved on target objects through block-copolymer templating (Figure 2c). In this way, the anticounterfeiting tag is not simply applied on the target object but it becomes part of the object itself, thus cannot be removed without leaving marks. We decided to embrace the true essence of nanotechnology, exploiting randomness due to thermodynamic fluctuations, kinetic factors, and defects that naturally arise during the self-assembly process. These nanopatterns can be considered as image-based physical unclonable functions (PUFs), where uniqueness is guaranteed by the intrinsic randomness of the self-assembly process that relies on uncontrollable manufacturing variability. Besides showing that the block-copolymer templating approach can be exploited even on rough and curved substrates, we demonstrate successful engraving of artificial fingerprints on a wide range of substrates, including diamond, quartz, Si, and SiO2. This approach can be easily extended to a wide range of materials.

Figure 2. a. Example of a fingerprint-like nanopattern obtained through self-assembly of block-copolymers. b. Typical defects of lamellar shaped block-copolymers, resembling minutiae features typical of human fingerprints. c. Realization of artificial fingerprints engraved on the target substrate, based on self-assembly of block-copolymer on the target object, selective removal of a polymer phase, and pattern transfer through reactive ion etching or wet chemical etching.

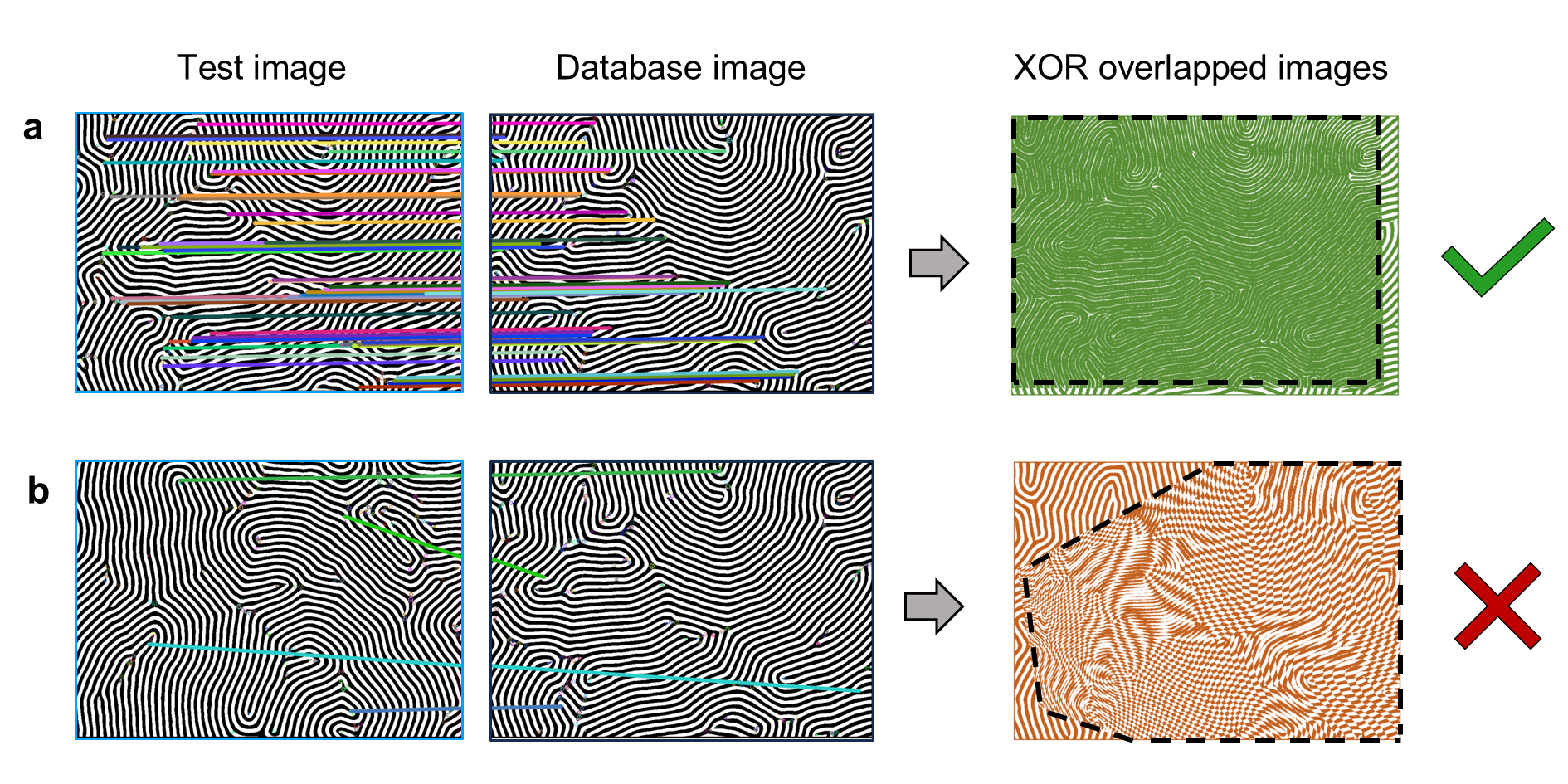

Besides demonstrating that these artificial fingerprints can be encoded in binary code matrices representing unique bit stream of information characterized by high uniqueness and entropy, we propose a strategy based on computer vision concepts for secure authentication/identification in a real-world scenario (Figure 3a and b). By engraving the fingerprint in SiO2 substrates, we demonstrate long-term reliable operation (tested over 6 months) and robustness against thermal treatment at cryogenic temperatures (-196 °C) and at high temperature (200°C), showing high robustness of artificial fingerprints even in harsh environmental conditions.

We envision that these results can shed new light on the realization of reliable PUF that embraces the inherent stochasticity of self-assembled materials a randomness sources.

Figure 3. a. Example of a successful authentication/identification and b. example of a non-successful authentication/identification through computer-vision based concepts based on the evaluation of the overlapping between a test image and a databased image.

The full paper can be found at https://www.nature.com/articles/s41467-024-54492-8. Data of our work are available on Zenodo (https://zenodo.org/records/13384908), codes are available on Zenodo (https://doi.org/10.5281/zenodo.14179662) and GitHub (https://github.com/ChiaraMagosso/NanoIdentifiers).

References

[1] Dalrymple, Brian E. "Fingerprints." The Forensic Laboratory Handbook: Procedures and Practice (2006): 117-141.

[2] Liu, Chi-Chun, et al. "Directed self-assembly of block copolymers for 7 nanometre FinFET technology and beyond." Nature Electronics 1.10 (2018): 562-569.

[3] Jacobberger, Robert M., et al. "Boundary-directed epitaxy of block copolymers." Nature Communications 11.1 (2020): 4151.

[4] Aono, Masakazu, and Katsuhiko Ariga. "The way to nanoarchitectonics and the way of nanoarchitectonics." Advanced Materials 28.6 (2016): 989-992.

[5] Yang, Geon Gug, et al. "Intelligent block copolymer self-assembly towards IoT hardware components." Nature Reviews Electrical Engineering 1.2 (2024): 124-138.

Follow the Topic

-

Nature Communications

An open access, multidisciplinary journal dedicated to publishing high-quality research in all areas of the biological, health, physical, chemical and Earth sciences.

Related Collections

With Collections, you can get published faster and increase your visibility.

Women's Health

Publishing Model: Hybrid

Deadline: Ongoing

Advances in neurodegenerative diseases

Publishing Model: Hybrid

Deadline: Mar 24, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in