Dry double-sided tape for adhesion of wet tissues and devices

Published in Electrical & Electronic Engineering

The resection of diseased or damaged tissues and the re-connection and mechanical sealing of the remaining healthy tissues are cornerstones of surgeries throughout the human history. The first record of wound closure by sutures tracks back to the dawn of human civilization thousands of years ago. Today, there are over 200 million major surgeries conducted every year in the world in which at least one surgical repair and closure of tissues are involved. Sutures are ancient yet the golden-standard method for most surgical repair and closure of tissues with a history of use over 3,000 years. Surgical staples are more modern technology first invented in Germany around 100 years ago and have been broadly adopted in numerous clinical applications.

However, despite being routine practice, sutures and surgical staples suffer from several challenges. Tissue damaging (puncturing through tissues) and non-continuous (point-wise closure rather than continuous seal) nature of sutures and staples causes various issues including scaring and leakage. For example, sutured or stapled anastomoses (surgical re-connection of tissues) of tissues and organs experience up to 30 % leakages and suture line failures, causing detrimental outcomes to patients and the health care system as a whole. Failure of surgical closures can lead to life-threatening bleeding and sepsis, significantly increased patient mortality, longer average hospital length of stay and substantial additional clinical costs amounting to several billion dollars annually in the U.S. alone.

Most recently, tissue adhesives have been developed to alleviate the challenges of sutures and staples. However, existing tissue adhesives still face limitations with unmet clinical needs, making them insufficient to address the challenges of sutures and staples. To better understand the state-of-the-art and unresolved challenges, we went out of our lab to hear the voice of experts. We interviewed 20+ surgeons with diverse surgical expertise in the nearby hospitals to learn the landscape of problems for existing tissue adhesives.

According to the surgical experts, there are four major unmet clinical needs for surgical adhesives and sealants, as they cannot 1) form adhesions on wet body fluid-covered tissue surfaces, 2) provide instant and strong adhesion for reliable tissue sealing, 3) offer stable long-term, sealing capability, 4) allow easy and reproducible usage with little to no learning curve. To engineers like us, these unresolved challenges in the existing technologies as well as the substantial clinical and economic burden inflicted by the problem made our heart beating fast with excitement and motivation to seek our way to solve these daunting yet tremendously important challenges.

As a research group working on adhesion of soft materials for many years, we were very familiar with the success of pressure-sensitive adhesives (PSA) such as various tapes from 3M (including mechanical engineers' all-time friend duct tape) in terms of making instant and robust adhesion on a variety of substrates. The PSA's outstanding capability of instant yet robust adhesion stems from their ability to forming intermolecular bonds such as van der Waals interactions with dry and clean surfaces almost instantly upon contact. However, unfortunately, the magical adhesion capability of PSA simply disappears on wet surfaces such as biological tissues. In a closer look, this stark incompatibility of the PSA on wet surfaces originates from a rather simple reason. In a wet physiological environment, a thin water layer presents on the surface of wet tissues due to their inherent hydrophilicity and/or surface roughness. This interfacial water layer between the PSA and the wet substrate effectively separates two surfaces and prevent the formation of intermolecular bonds, and therefore adhesion.

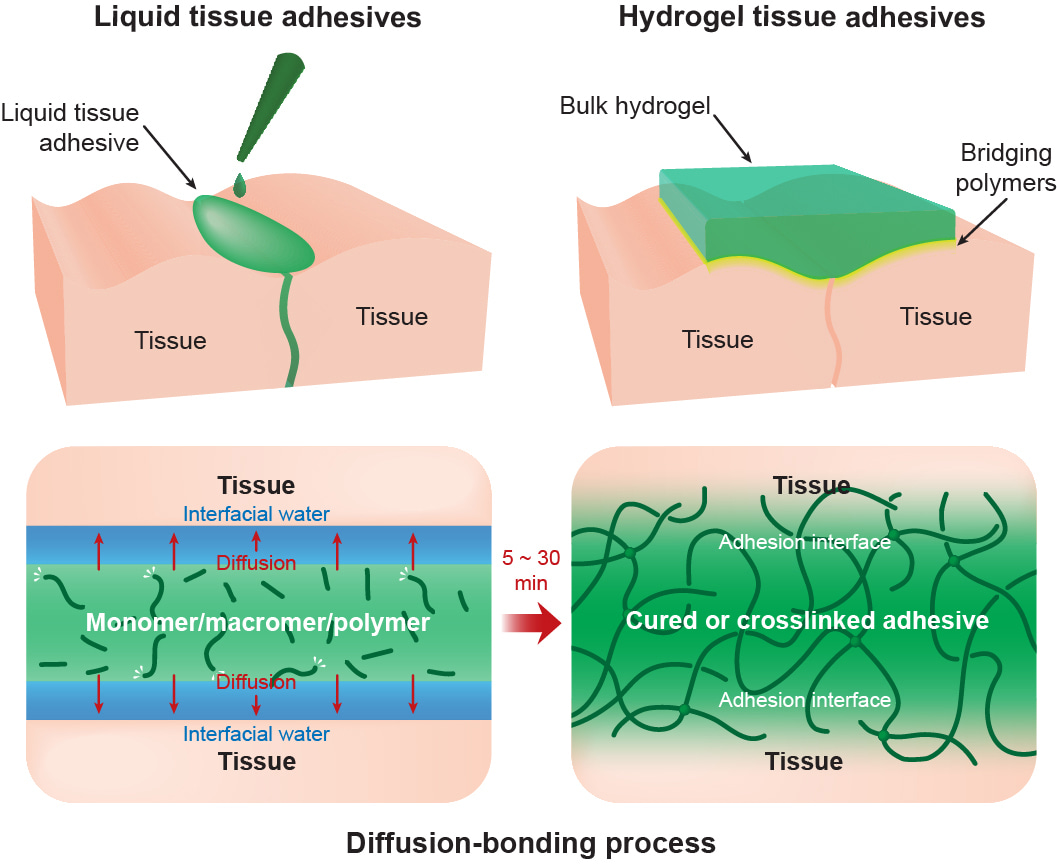

In contrast to the PSA, most existing tissue adhesives rely on a diffusion-based mechanism to form adhesion on wet surfaces. Adhesive molecules diffuse through the interfacial water layer on the wet tissue surface and subsequently crosslink with the polymer networks of the underlying tissue. However, the diffusion-based mechanism gives rise to a set of limitations and problems in existing tissue adhesives. The diffusion process through the interfacial water layer significantly slows down adhesion formation over minutes. The interfacial water also interferes with the diffusion or crosslinking process of the adhesive molecules via dilution, premature curing, and insufficient diffusion, leading to weak and unstable adhesion on wet surfaces. As we understood the problem better, it became clearer to us that we should innovate the mechanism for wet adhesion itself instead of tinkering different chemistries and materials within the same diffusion-based mechanism to address the challenges and limitations of existing tissue adhesives.

A solution came unexpectedly from a very unlikely place. In one rainy day, I got a silly question when I saw a spider web hanging at the small corner of a tree – How can spiders capture insects in rainy days? There are a lot of spider species living in rain forests where humid and rainy days are more common than dry days, so they should have evolved to deal with "wet adhesion" to capture prey – and it was true. The spider web glue contains hygroscopic compounds to remove interfacial water to enable adhesion in humid conditions (you can find more in a related research article by Singla et al.). This was my eureka moment putting a light bulb on my head, saying “I think I find a way to make PSA for wet surfaces!”

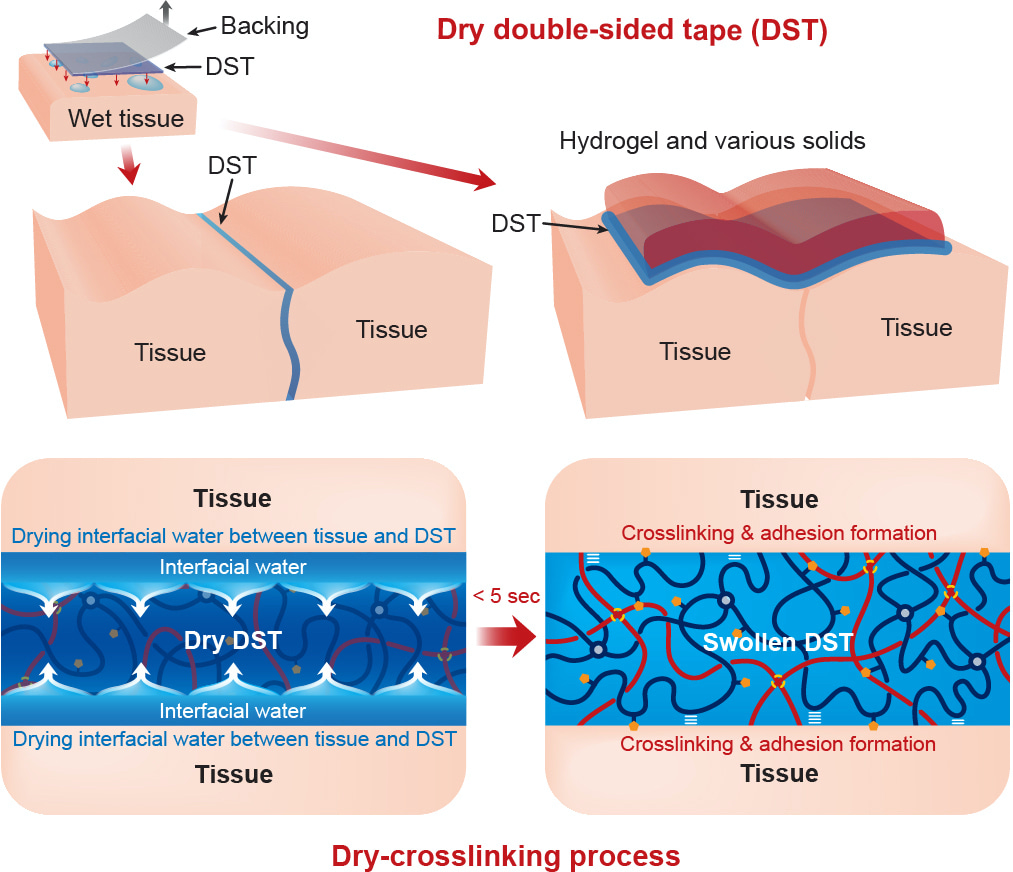

Inspired by the spider web glue, we proposed a dry-crosslinking mechanism to achieve instant robust adhesion on wet surfaces. Instead of diffusing adhesive molecules through the interfacial water layer, instant yet robust adhesion can be formed by removing the interfacial water to allow instant crosslinking by intermolecular interactions, followed by quick covalent crosslinking between the adhesive and the host tissue. Also, we wanted to incorporate the dry-crosslinking mechanism in the form of double-sided tape (DST) to introduce the advantage and convenience of the PSA for tissue adhesives and their clinical applications.

While implementing the conceptual idea into reality was a hard and non-trivial job, we made it happen eventually. To implement the dry-crosslinking mechanism, we engineered a dry DST which can rapidly absorb the interfacial water to effectively dry the wet tissue surface. By carefully tuning the chemical composition of the DST, the swollen DST can form instant intermolecular crosslinks on the dried tissue surface in few seconds, quickly followed by covalent crosslinks with primary amine groups on the tissue surface to endow stable adhesion in a wet physiological environment over days. We also designed the swollen DST to become a layer of tough hydrogel with a high fracture toughness to provide tough and robust interfacial adhesion following our early pioneering works on tough bonding of hydrogels (Yuk et al., Nature Materials 15, 190-196, 2016; Yuk et al., Nature Communications 7, 12028, 2016), in which we proposed the concept of bulk-interface synergy to achieve tough hydrogel adhesion. Personally, it was truly amusing to find that our earlier works on robust hydrogel adhesion laid the foundation for the DST as well.

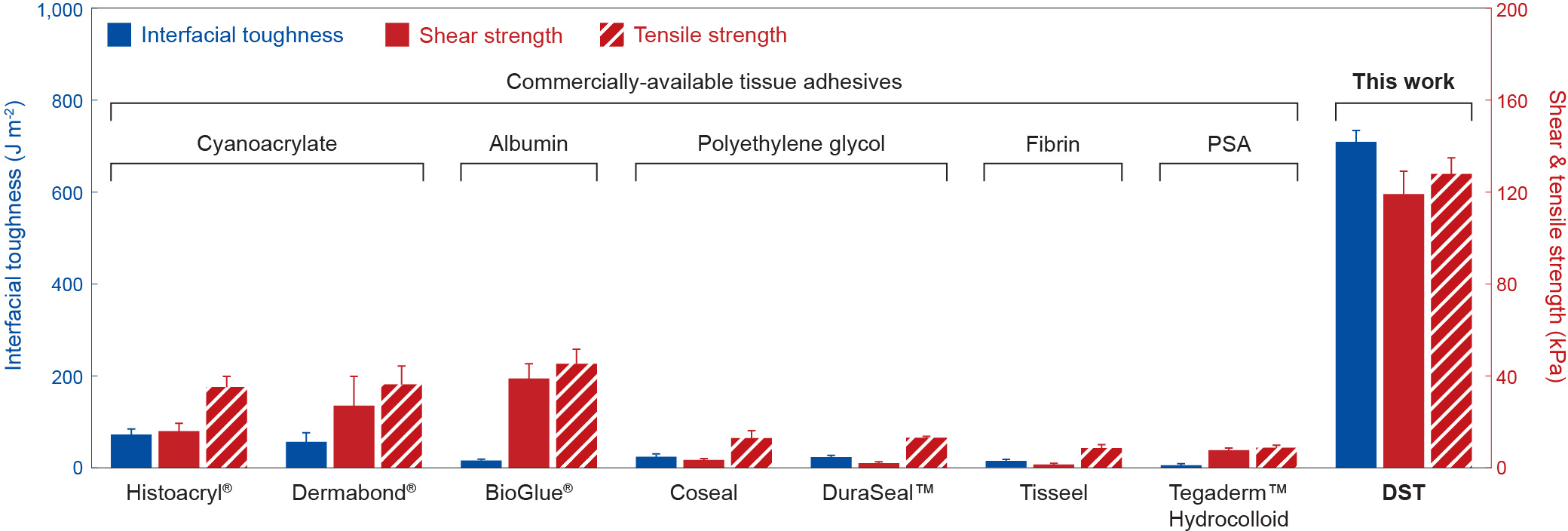

When we tested the adhesion performance of the DST, our excitement became even greater. The adhesion performance of the DST in terms of interfacial toughness, shear strength, and tensile strength significantly outperformed those of existing commercially-available tissue adhesives while the speed of adhesion was unprecedently fast – less than 5 seconds just by gentle pressure around 1 kPa without the need of any other equipment or external stimulus. Furthermore, we carefully chose chemical compositions of the DST to ensure biocompatibility, tunable biodegradability, and long-term storage. Looking back to the list of unmet clinical needs in tissue adhesives and sealants that we learned from the clinical experts, we were happy to find that we addressed all of them in our DST - The DST can 1) form adhesions on wet body fluid-covered tissue surfaces, 2) provide instant and strong adhesion for reliable tissue sealing, 3) offer stable long-term, sealing capability, 4) allow easy and reproducible usage with little to no learning curve.

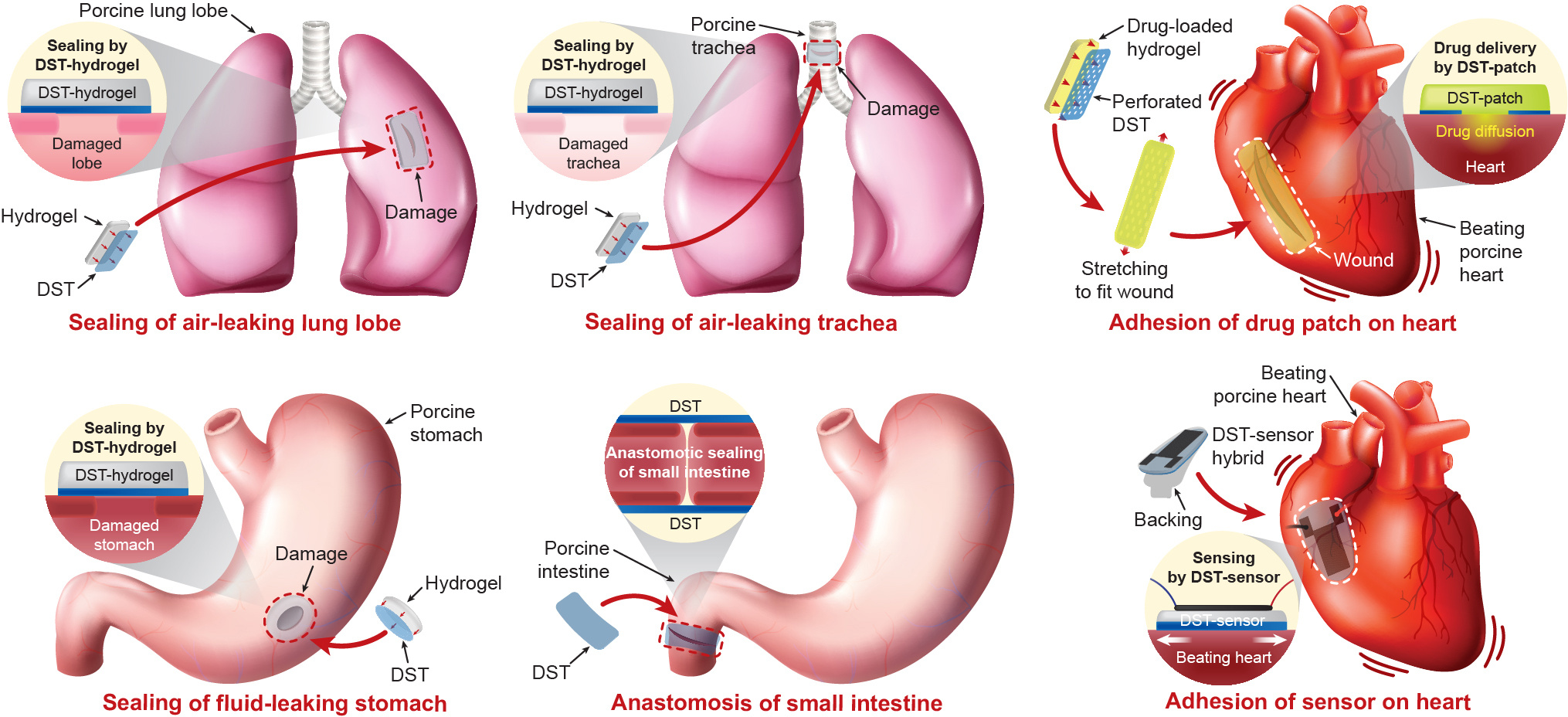

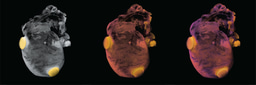

Enabled by a unique set of advantages of the DST, we demonstrated several proof-of-concept applications of the DST ranging from instant robust sealing of injured tissues to robust sutureless integration of implantable devices on wet and dynamic organs. We are also actively pursuing a broad range of pre-clinical collaborations with numerous biomedical and clinical experts to translate our new technology into real-world applications. In one day, we hope that the DST can replace sutures and staples to benefit millions of patients as well as open new possibilities for bio-integrative devices. It is always amusing to imagine how our technological contribution can change the world into a better place in the future.

For more details, check out our paper “Dry double-sided tape for adhesion of wet tissues and devices” on Nature.

Follow the Topic

-

Nature

A weekly international journal publishing the finest peer-reviewed research in all fields of science and technology on the basis of its originality, importance, interdisciplinary interest, timeliness, accessibility, elegance and surprising conclusions.

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in