In traditional chemical engineering, endothermic reactions such as methane pyrolysis and dry reforming are energy-intensive due to suboptimal heat transfer mechanisms. These processes necessitate significant energy input, which is often inefficiently managed, leading to extra energy consumption and environmental impact. To address these challenges, electrification has emerged as a viable solution, enabling more effective and enhanced heating methods that can substantially improve process efficiency.

Electrification in chemical processes involves the direct use of electrical energy to heat the reactants, surpassing conventional combustion-based heating. This method offers several advantages, including precise temperature control, rapid heating rates, and reduced thermal inertia, which are critical for endothermic reactions where maintaining a consistent reaction temperature is vital for optimal performance.

In the realm of hydrogen production from methane, pioneering efforts by industry giants like BASF and TOPSOE have demonstrated the potential of electrification. These demonstration projects showcase how electrification can lead to more compact reactor designs, enhance energy efficiency, and potentially lower the carbon footprint of hydrogen production processes.

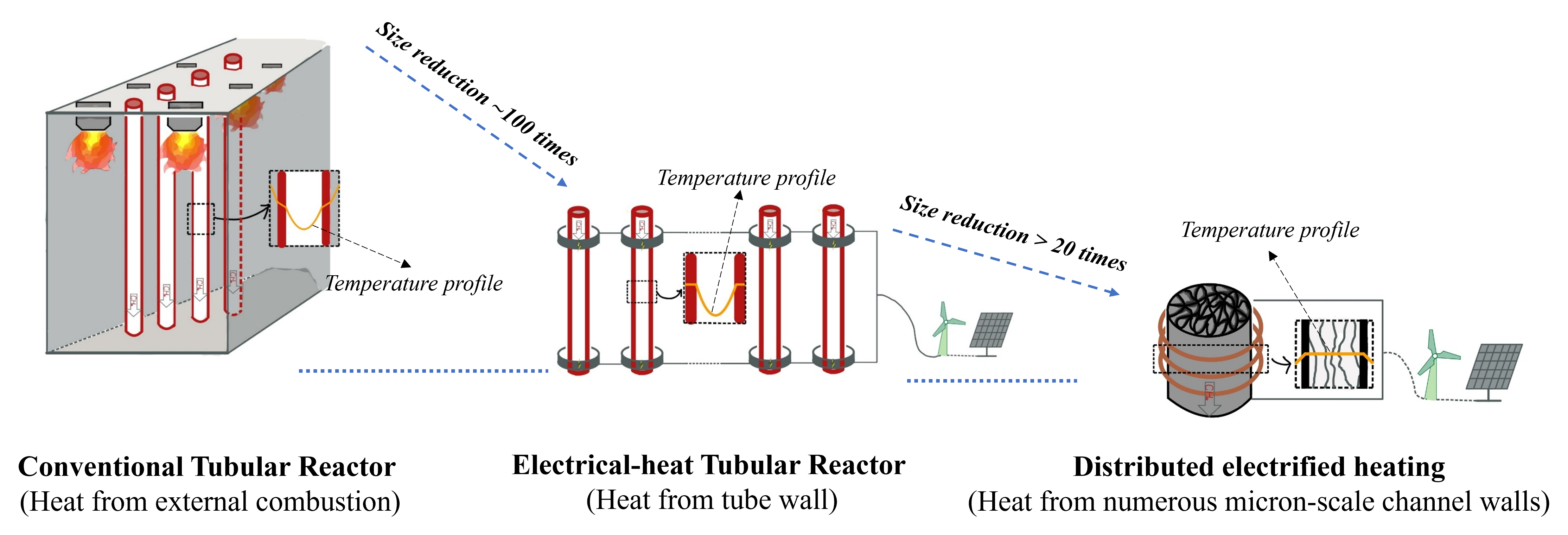

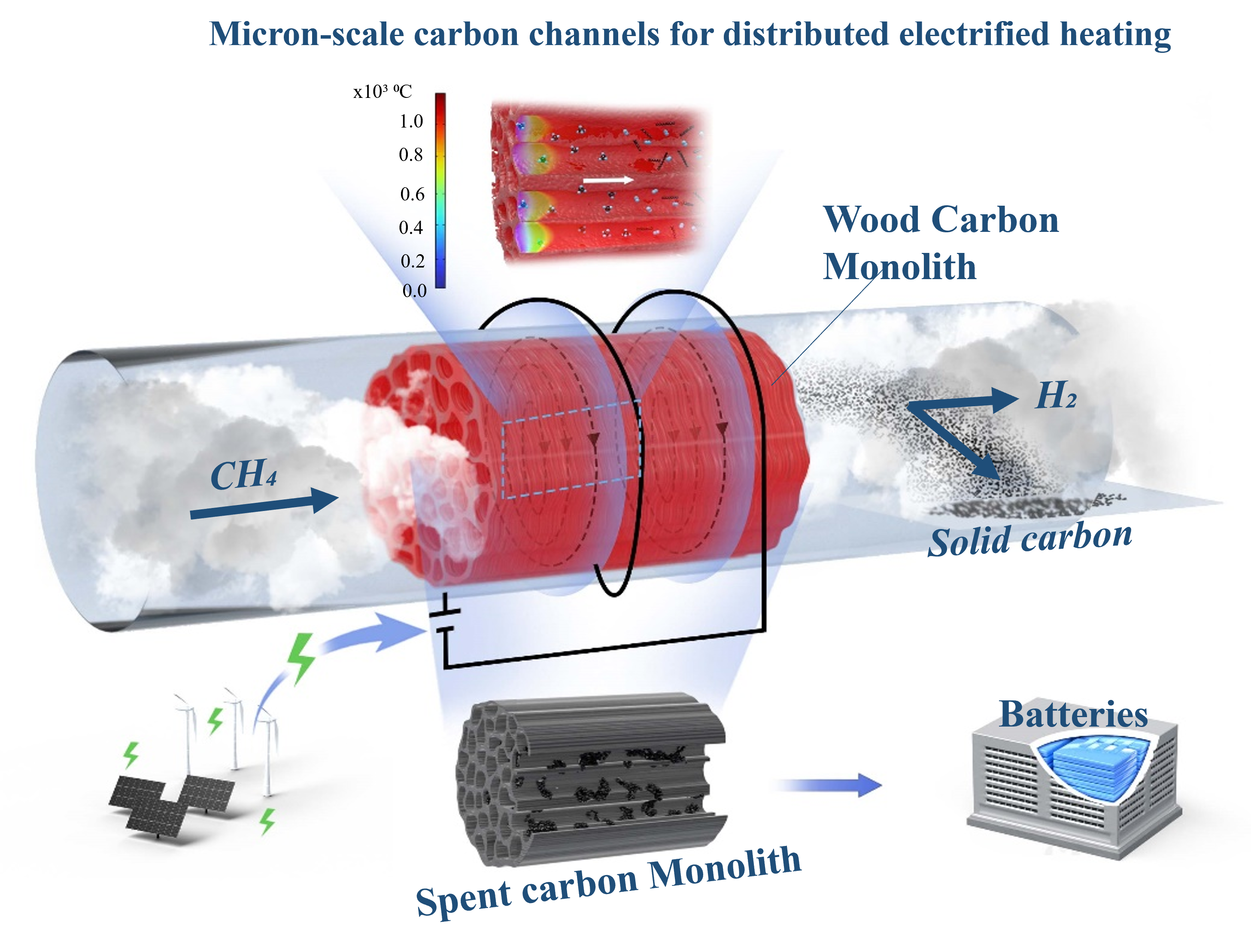

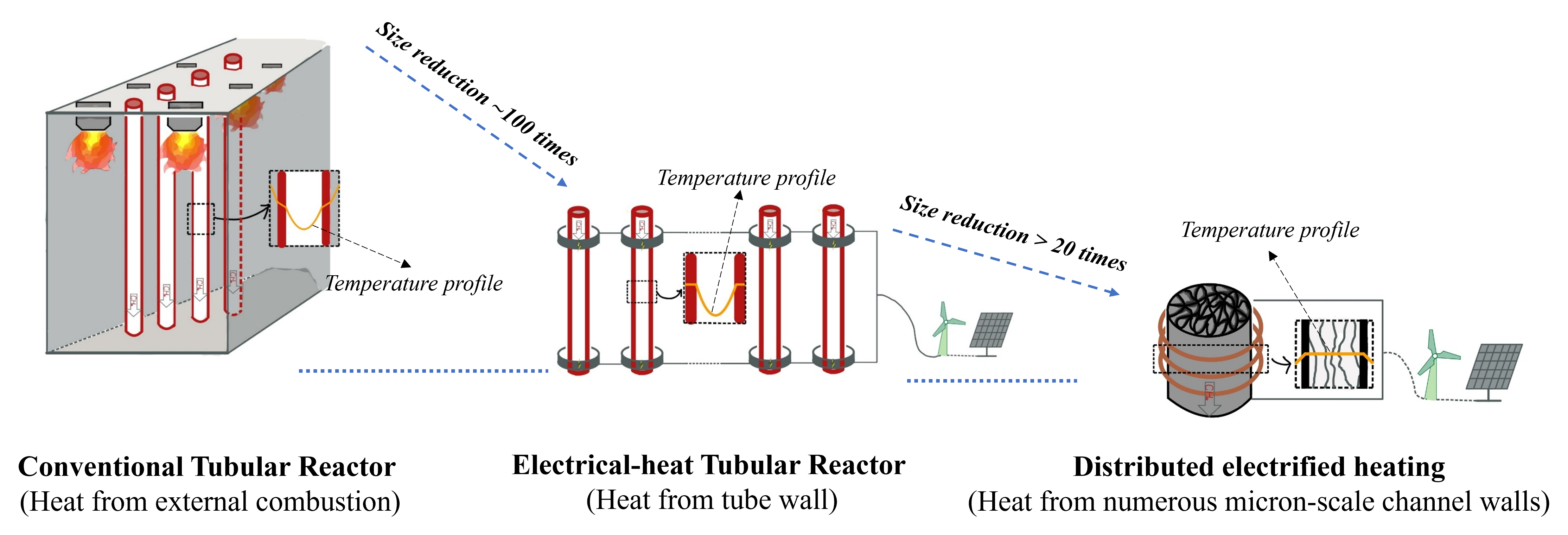

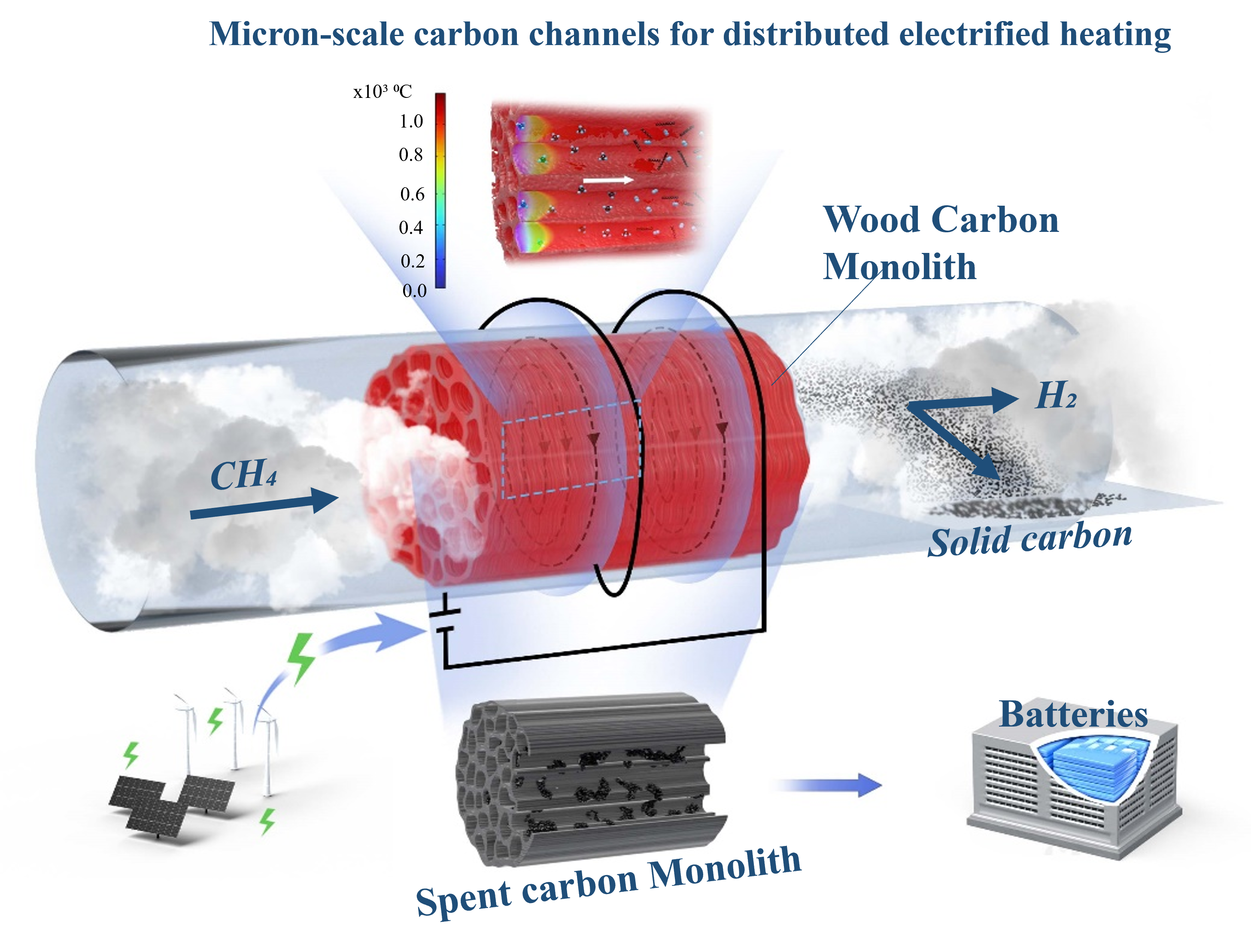

Inspired by the integration of bio-based materials and electrification, our research proposes a novel distributed electrified heating approach for methane pyrolysis and dry reforming. This technique involves distributing gaseous reactants through an array of electrically heated, regular micron-scale channels, facilitating rapid and uniform heating. By effectively transferring heat to the reactants and maintaining a consistent reaction temperature, this approach enables efficient conversion and high selectivity for desired products, aligning with the thermodynamic equilibrium of the reactions.

Our distributed electrified heating approach represents a significant advancement over traditional elongated reactor tubes and external furnaces, leading to an energy-concentrated and ultra-compact reactor system. Preliminary results have shown remarkable achievements, such as 100% conversion of methane at high gas hourly space velocities (GHSV) of 3000 h-1 at 1150°C, using a structured porous charcoal reactor, and maintaining performance stability for extended periods.

Computational fluid dynamics (CFD) simulations further corroborate the effectiveness of the distributed micron-scale channel structure and electrified heating in achieving optimal reaction conditions. These findings suggest that both the geometry and electrification are crucial for the success of this innovative heating approach.

In conclusion, the distributed electrified heating approach offers a promising pathway for revolutionizing methane conversion processes, enhancing the sustainability and efficiency of hydrogen production. As the global energy sector moves towards greener and more sustainable solutions, such approaches underscore the importance of innovation in meeting the challenges of energy transition and achieving a carbon-neutral future.

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in