Gram-scale bottom-up flash graphene synthesis

Published in Electrical & Electronic Engineering

Yes, graphene, which presently sells for $67,000 to $200,000 per ton, can be made from trash which people will pay us to take off their hands.

Bulk graphene synthesis is limited by both the multiple steps complicating the formation process and the quality of the produced graphene. Here we develop a flash joule heating process to prepare high quality graphene from any carbon sources. The process is termed “flash graphene” and it has an exciting scaling potential. This could greatly affect the selling price of graphene, lowering it to a price-point so that it could become an additive in large-scale commodity materials such as even asphalt and concrete.

Currently bulk graphene synthesis is mainly from the top-down exfoliation of graphite either physically, chemically or electrochemically, affording AB-stacked (Bernal) graphene nanoplatelets that are tens of nm in thickness. With this flash graphene magic wand approach, we can solve both process and feedstock problems of graphene synthesis.

From our experience with laser-induced graphene 10.1002/adma.201803621, we learned that graphene can be synthesized without catalysts from many carbon feedstock in less than 1 second if the temperature reaches ~3000 K by using a laser. Then an article in Science (10.1126/science.aan5412) hinted to us that a high temperature pulse is possible with Joule heating. A quick calculation for heating 20 mg of carbon to 3000 K showed that we’d need at least a 10 kW power supply. The only available option was to use a capacitor discharge. Bingo, Duy Luong in our group showed that high quality graphene could be synthesized in this way. In this Nature article, we have successfully converted carbon black, coal, coke, waste food, mixed waste plastic, rubber tires and many other materials into graphene.

The temperature of the flash process reaches more than 3000 K in less than 100 milliseconds. This is sufficient to break all chemical bonds in any carbon material, subliming out every non-carbon element, resulting in flash graphene. The graphene forms so rapidly that it cannot AB-stack into the graphite-like arrangement. The layers are mis-oriented or turbostratic. This is a huge advantage since it affords easy dispersion of flash graphene-derived material in composites and liquids.

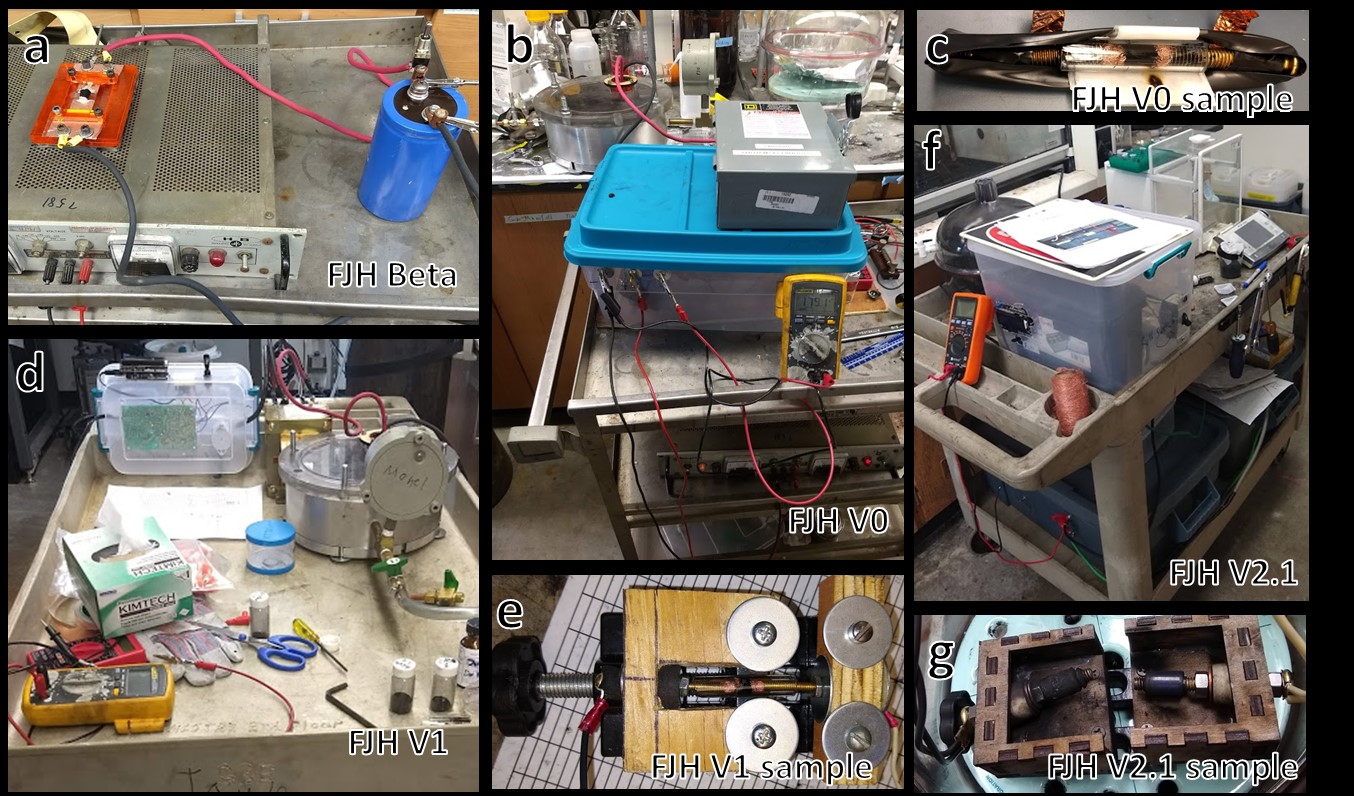

So how did the equipment progress in the lab? Our first FJH Beta only consisted of a capacitor, toggle switch and sample, as shown in a. After it proved that small amounts of graphene could be prepared by the approach of rapid high temperature heating, we upgraded to a more contained system FJH V0 with a bigger capacitor bank as shown in b. The sample reactor was crude: two brass screws compressed against the carbon source by the tension of electrical tape as in c. This system produced graphene in some of the samples. However, the graphene quality was low and the consistency was not good. We then upgraded the system once more to a better designed electrical system, FJH V1 with microcontroller seen in e. This system allowed us to synthesize flash graphene with very high quality. The sample stage was also customized manually to speed up the flashing process and enable the graphene conversion from many other carbon sources. However, the system did not meet electrical safety standards. Therefore, we redesigned the system to FJH V2.1 (f) that is safe to use and has more energy storage through a larger capacitor bank. The sample stage was further customized from laser cut wood parts for consistency as in g for FJH 2.1. This system is small enough to fit nicely on a cart but powerful enough to make 1 g of graphene per batch in a single flash.

We envision this small system can be scaled up to make tons of flash graphene each day through multiple automated flashes. This is being done now by us through a Department of Energy grant to convert 1 kg per day of US coal into graphene. Might that allow us to breathe new life into coal without burning it?

30 to 40% of all food, worldwide, is discarded because it goes bad. Hitting landfills it becomes carbon dioxide an even worse, methane, upon decomposition. But now food can be fixed into graphene rather than decomposing to contribute to undesired emissions. Graphene will very slowly, if ever, enter the carbon cycle again.

The hope of having a repository for mixed plastic waste conversion to high value graphene is enormous. This flash graphene can be mixed into cement to increase the compressive strength of concrete; thus, further reducing the concrete’s carbon dioxide emission footprint. By doing so, we can lessen both greenhouse gas emissions and plastic waste problems in this one technology.

The process is being scaled by a newly founded company, Universal Matter Ltd. We wish Universal Matter great success in building automated production plants that can be distributed around the world to bring in a new era of graphene materials while lessening both greenhouse gas emissions and the human waste footprint, all at the flash of a magic wand.

Follow the Topic

-

Nature

A weekly international journal publishing the finest peer-reviewed research in all fields of science and technology on the basis of its originality, importance, interdisciplinary interest, timeliness, accessibility, elegance and surprising conclusions.

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in