Journal Club | Length Scale Matters

Published in Chemistry

With the advent of fibre based materials in the mid-1960s much attention was given to improving the composition and processing of functional fibres. The advances of fibre based technologies became quickly evident and, focusing on processing and application, advanced fibre technology was soon considered as a mature field with comparable low level of innovation. A rising demand on high-performance materials recently focused attention on fibre technologies once again. Characterized by their stiffness and strength, fibres became a valuable component in fibre based materials and composite materials where high-end mechanical properties paired with light weight are needed.

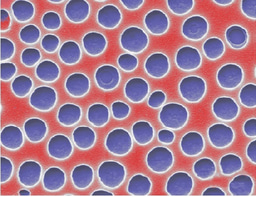

So what makes these fibres so strong? The microstructure of fibres shows a distinct oriented hierarchical structure spanning multiple length scales. Crystallization and orientation of the polymer chains during the fabrication process form discrete domains measuring 10-50 nm in width and often referred to as nanofibrils. Nanofibrils form bundles on a 100-500 nm length scale which eventually form the fibre. Clearly, changes in processing conditions have a direct effect on the microstructure and on the mechanical properties. It is therefore not surprising that extensive work was put into developing and optimizing the processing conditions. Less investigated, but evidently important, remained fracture mechanisms and fibre failure under load.

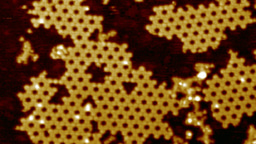

In their recent publication in ACS Applied Materials & Interfaces, which was also featured on the journal front cover, a team led by Yuris Dzenis from the University of Nebraska-Lincoln and Kenneth Strawhecker from the U.S. Army Research Laboratory looks at the lateral interfacial interaction between fibril bundles. “We still know very little about the complex failure processes in advanced fibres. We need to better understand their behaviour before we can optimize them” Dzenis said, striving to close the gap in our understanding of fibre failure. While bulk fibre mechanical properties as well as interfacial interaction of single fibrils on the nanoscale have been investigated, their novel technique now enables getting insight into fibre failure mechanisms at an intermediate length scale. This is important because post-mortem analysis of fractured high performance fibres revealed fibrillated segments and indicates that fibre failure typically occurs in nanofibril bundles at an intermediate length scale.

On the nanoscale, AFM indentation techniques can give information about delamination of nanofibrils. However, established experimental techniques allowing characterisation of interfacial delamination of fibril bundles, which are an order of magnitude larger in scale, were lacking. Originally starting as a summer internship project at the Army Research Lab, Dzenis’s then PhD student Taylor Stockdale developed a sample preparation technique which allowed to peel open an ultrahigh molecular weight polyethylene (UHMWPE) and a poly(p-phenyl terephthalamide) (PPTA) fibre to gain access to the fibre interior without through-thickness fracture. Using this technique, the authors were also able to avoid artefacts close to a fracture site which often invalidate measurements when using alternative fracture techniques. Both fibres differ in their molecular characteristics and are fabricated by using different processing techniques. UHMWPE fibres are produced by gel spinning followed by additional drawing at elevated temperature which allows the flexible polyethylene chains to form a highly extended chain structure. Conversely, PPTA fibres are produced by dry-jet wet spinning which allows orientation of the rigid-rod polymer chains through shear flow.

The initial objective of the project was to test the feasibility of quantitative large-force probing on the fibril bundles using the newly developed sample preparation technique. While analysing the results from the nanoindentation experiments, the authors were puzzled about the relatively low energy needed to separate the flexible chain UHMWPE fibril bundles, while much more energy was needed for separating the rigid-rod PPTA fibril bundles. “Based purely on chain flexibility, one could expect the opposite”, Dzenis explains the intriguing result. Digging deeper into this matter and comparing images of fracture tests, the team found separation of the nanofibril bundles which propagate much farther along the fibre length in UHMWPE fibres when compared to the PPTA fibres. These results indicate that the lateral interactions at the intermediate scale in rigid-rod PPTA fibres are stronger compared to those in flexible UHMWPE fibres.

But that was not enough. Comparing the amount of absorbed energies on three different length scales provided another surprise. The absorbed energy increased proportionally to increasing length scale following a power law. This implies that different mechanisms of lateral interaction must be responsible for separation of nanofibrils, fibril bundles and entire fibres. Looking into the structure of fractured fibres on the different scales, the team found similar crack bridges as an evidence for self-similarity, a phenomenon which often follows a power law in physics.

The question why fibres fail on the intermediate length scale, however, remains unanswered. The weakest link theory would suggest that failure occurs through the lowest energy absorption mechanism among the nanofibrils. One theory suggests that AFM indentation measurements on nanofibrils maps only localized events of low energy of nanofibril separation. This does not reflect the extended structure which, depending on the processing conditions, can be dominated by disorientation in the nanofibril morphology. Answers to this question will be given in future studies, which will focus on understanding the load transfer across different length scales.

The original article can be found here:

Stockdale, T. A. Cole, D. P. Staniszewski, J. M. Roenbeck, M. R. Papkov, D. Lustig, S. R. Dzenis, Y. A. Strawhecker, K. E. Hierarchical Mechanisms of Lateral Interactions in High-Performance Fibers. ACS Appl. Mater. Interfaces 12 (2020) 22256 – 22267 DOI: 10.1021/acsami.9b23459

Image credit: Joel Brehm, Taylor Stockdale, Yuris Dzenis/University of Nebraska

Follow the Topic

-

Nature Communications

An open access, multidisciplinary journal dedicated to publishing high-quality research in all areas of the biological, health, physical, chemical and Earth sciences.

Related Collections

With Collections, you can get published faster and increase your visibility.

Women's Health

Publishing Model: Hybrid

Deadline: Ongoing

Advances in neurodegenerative diseases

Publishing Model: Hybrid

Deadline: Mar 24, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in