Lightweight single-phase Al-based complex concentrated alloy with high specific strength

Published in Materials

Metallic alloys with low density and high strength remain in high demand for the aerospace industry. Reducing material density is the best way to make aircraft lighter and boost performance—about 3 to 5 times more effective than strengthening it in other ways. Currently, Al-based alloys have the best combination of required properties after decades of development. However, the production of high-strength aluminum(Al) alloys involves a series of intricate heat treatment and deformation processes. In addition, the strength of aluminum alloys is approaching their limit, and further reduction in density poses challenges, making it hard to significantly enhance their specific strength (the ratio of strength to density). It is crucial to further decrease the density of aluminum alloy while ensuring that it maintains a certain level of strength.

Recently, a revolutionary alloy design strategy, namely high entropy alloys or more strictly, called as complex concentrated alloys (CCAs), was widely applied in numerous alloy systems and held tremendous potential for practical application. Applying the CCA design concept to Al alloys has the potential to add more lightweight elements, offering an opportunity to significantly reduce the density of Al alloys while achieving outstanding mechanical performance. Although a few Al-containing CCAs were reported, their microstructure often exhibits a mixture of various brittle intermetallic compounds, resulting in deterioration of mechanical properties. Thus, a critical issue must be resolved before these lightweight CCAs can be truly utilized as engineering materials, namely, how to obtain single-phase solid solutions and eliminate formation of the multiple intermetallic compounds in lightweight CCAs. This issue actually covers the following aspects:

- Difficulty in single phase formation. Due to significant differences in atomic radius and electronegativity between components, alloying more constituents often result in high enthalpy of mixing and low excess configurational entropy, which always favor formation of chemically ordered intermetic compounds (ICs).

- Poor strength and ductility. Lightweight CCAs usually contain multiple ICs and fracture in a brittle mode with limited dislocation operation, which can be attributed to insufficient slip systems and weak boundaries between the ICs and matrix.

- Reliable design principles. The composition design criteria, originally proposed for the synthesis of dilute solid solutions, are usually not suitable for lightweight CCAs due to the heavy alloying.

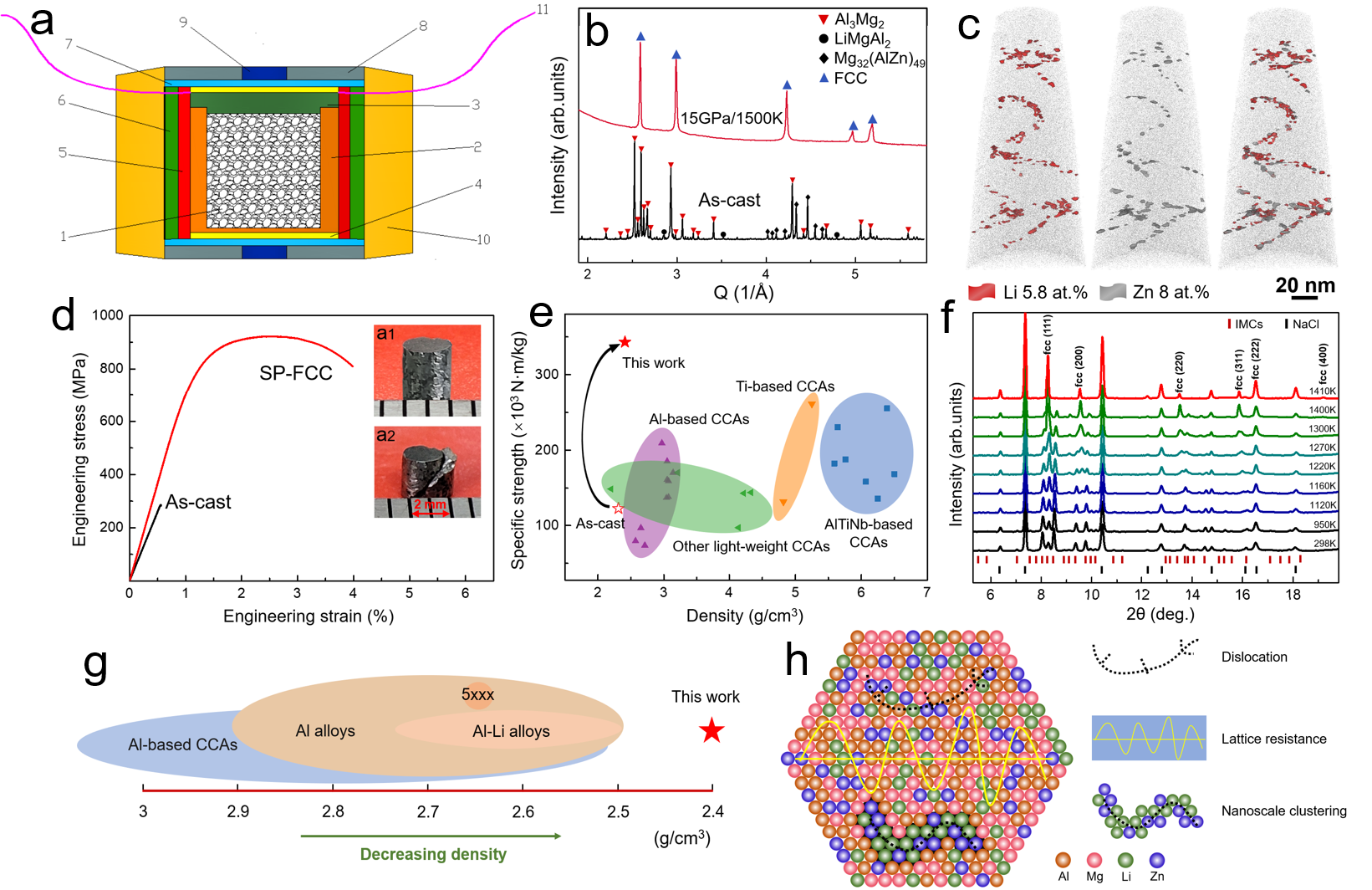

To address the aforementioned challenges, we employed pressure, a powerful tool to modify the physical and chemical properties of elements (e.g., size and electronegativity) with the aim of promoting phase transition from ICs to random solid solutions. By combinging high pressure and high temperature, we have successfully synthesized a bulk single-phase Al-based CCA, Al55Mg35Li5Zn5, with an ulta-low density of 2.40 g/cm3 and an ultra-high specific strength of 344×103 N·m/kg (typically ~200×103 N·m/kg in conventional Al-based alloys). Particularly, we have scrutinized the formation and strengthening mechanisms of the fabricated single-phase CCA via a comprehensive set of experimental characterization techniques and theoretical calculations.

Figure 1. (a) Schematic drawing of large volume press used for the pressure generation. (b) Synchrotron XRD patterns of the as-cast sample (black) and the sample synthesized at 15 GPa and 1500 K by LVP (red), revealing the synthesis of single-phase FCC structure. (c) APT reconstruction of the HPHT-synthesized sample. Maps of 5.8 at.% Li, 8 at.% Zn iso-concentration and their overlap are displayed to depict local chemical fluctuations. (d) Stress-strain curves of the as-cast and SP-FCC Al55Mg35Li5Zn5 CCAs at room temperature under compression. The insets a1 and a2 are the optical images of the SP-FCC sample before and after compression, respectively. (e) Specific fracture strength and density of the SP-FCC Al55Mg35Li5Zn5 CCA, in comparison with those of various lightweight CCAs. (f) Synchrotron XRD patterns of the Al55Mg35Li5Zn5 alloy as a function of temperature when subjected to a compression pressure of 10 GPa, which reveals phase transition from multiple IMCs to the single-phase FCC solid solution. (g) Density comparison of our developed SP-FCC CCA with other Al-based CCAs, conventional Al alloys including Al-Li alloys and 5xxx series Al alloys. (h) Schematic illustration of strengthening mechanisms in the HPHT-synthesized SP-FCC CCA.

Our results will be of great interest to the readership owing to the following highlights:

- We synthesized a single-phase face-centered cubic Al-based CCA for the first time. The formation is attributed to the decreased difference in atomic size and electronegativity between the solute elements and Al under high pressure, as well as the synergistic high entropy effect caused by high temperature and high pressure.

- We proposed an effective approach, namely, high pressure and high temperature, to eliminate the ICs in lightweight CCAs. We have proven that this approach is effective in other lightweight alloys. Additionally, we established design criteria for achieving a single-phase solid solution in Al-based CCAs under high pressure, which also offers an opportunity for better understanding high-pressure physics in alloy design.

- Outstanding properties were achieved. The ultralow density is attributed to the incorporation of a significant amount of light elements Li and Mg. The principal strengthening mechanisms in the synthesized SP-FCC Al-based CCA results from a combination of strengthening from high solid solution, dislocations, and nanoscale chemical fluctuations.

- The newly developed alloy has great potential for industrial uses. The newly designed CCA can be prepared by large volume press technique, making them feasible for preparation of bulk samples.

Therefore, we believe that our work will provoke broad interests in the fields of lightweight materials, high-pressure physics and high-entropy alloys. In our humble opinion, the current findings offer not only deepen our understanding of high-pressure physics in alloy design, but also a new avenue for synthesizing lightweight CCAs with low density and high strength-to-weight ratio in a vast compositional space.

Follow the Topic

-

Nature Communications

An open access, multidisciplinary journal dedicated to publishing high-quality research in all areas of the biological, health, physical, chemical and Earth sciences.

Related Collections

With Collections, you can get published faster and increase your visibility.

Women's Health

Publishing Model: Hybrid

Deadline: Ongoing

Advances in neurodegenerative diseases

Publishing Model: Hybrid

Deadline: Mar 24, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in