We live in a world of matter. To meet some of civilization’s greatest needs, it is critical to create new materials with better properties (e.g., stronger, lighter, more energy-efficient, more eco-friendly). To achieve that, it is imperative to have the ability to design materials with desired properties at the most fundamental level - the atomic scale. This is the so-called “inverse design problem” and is often thought of as the Holy Grail in materials science. Conventional materials discovery and design processes largely rely on empirical, trial-and-error observations, which are expensive and time-consuming. As of today, only a tiny fraction of theoretically possible materials have been discovered and characterized.

The idea of direct manipulation of individual atoms to design materials at the nanoscale is not new. In 1959, Richard P. Feynman described the opportunity of designing materials one atom at a time in his famous talk entitled “There is Plenty of Room at the Bottom”, inspiring the fields of nanotechnology and nanoscience. However, decades later, there was still no computational approach capable of designing materials atom-by-atom. Our initial goal for the work was to understand what kind of challenges (e.g., theoretical, numerical, computational) need to be overcome to achieve the goal of designing materials with atomic-level precision. To search for the optimal distributions of atoms, it is essential to estimate the contribution of each atom in the design space to a desired property such as modulus and strength. However, it is difficult to evaluate the contribution of each atom accurately and efficiently at the same. For instance, the contribution of an atom can be estimated as how much the desired property changes when the atom is in the materials system and when it is removed. Theoretically, this “one-at-a-time” approach can be done but computationally, it is very expensive. In our Nature Communications paper on “Nano-topology optimization for materials design with atom-by-atom control”, we implemented sensitivity analysis and sensitivity filtering techniques to estimate the contribution of all the atoms in the materials system at once, allowing us to efficiently search for the optimal distributions of atoms for various desired properties.

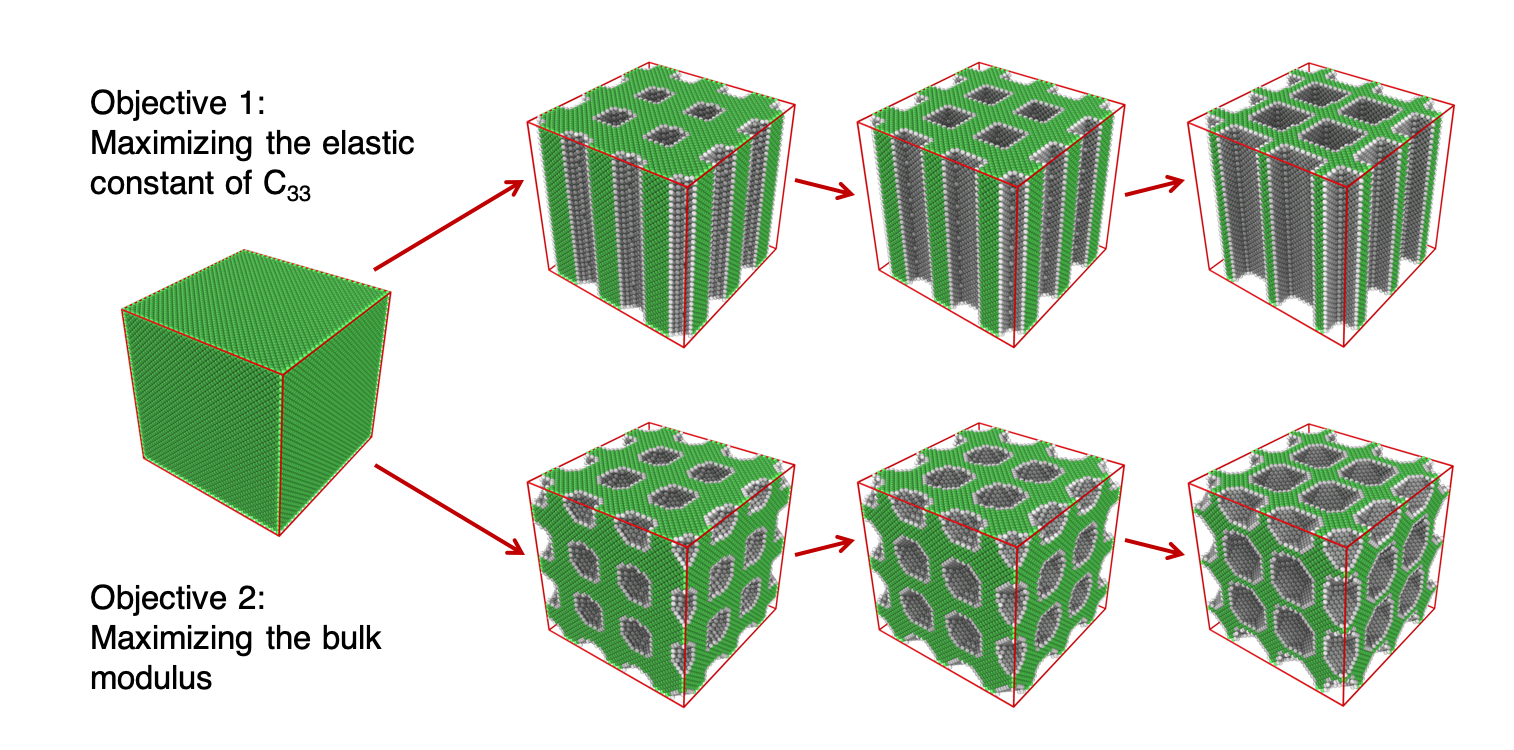

We applied our approach called Nano-Topology Optimization (Nano-TO) to design nanostructured materials to maximize elastic properties (see Figure 1). The performance (bulk modulus) of our optimized designs surpasses that of the gyroid and other triply periodic minimal surface structures, which are believed to have superior properties due to their unique geometric features. Surprisingly, the bulk modulus of the optimized designs also exceeds the theoretical maximum (Hashin–Shtrikman upper bound). After further investigation, we found that Nano-TO can utilize the surface effect in the design of nanostructured materials. By optimizing the surface topology at the nanoscale, the Hashin–Shtrikman upper bound for the bulk modulus can be exceeded. We are very excited about this new research direction. It is envisioned that a broad array of novel nanomaterials and nanomachines with unprecedented performance can be designed using Nano-TO.

Link to paper: https://www.nature.com/articles/s41467-020-17570-1

Follow the Topic

-

Nature Communications

An open access, multidisciplinary journal dedicated to publishing high-quality research in all areas of the biological, health, physical, chemical and Earth sciences.

Related Collections

With Collections, you can get published faster and increase your visibility.

Women's Health

Publishing Model: Hybrid

Deadline: Ongoing

Advances in neurodegenerative diseases

Publishing Model: Hybrid

Deadline: Mar 24, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in