Super Graphene-Skinned Materials

Published in Physics

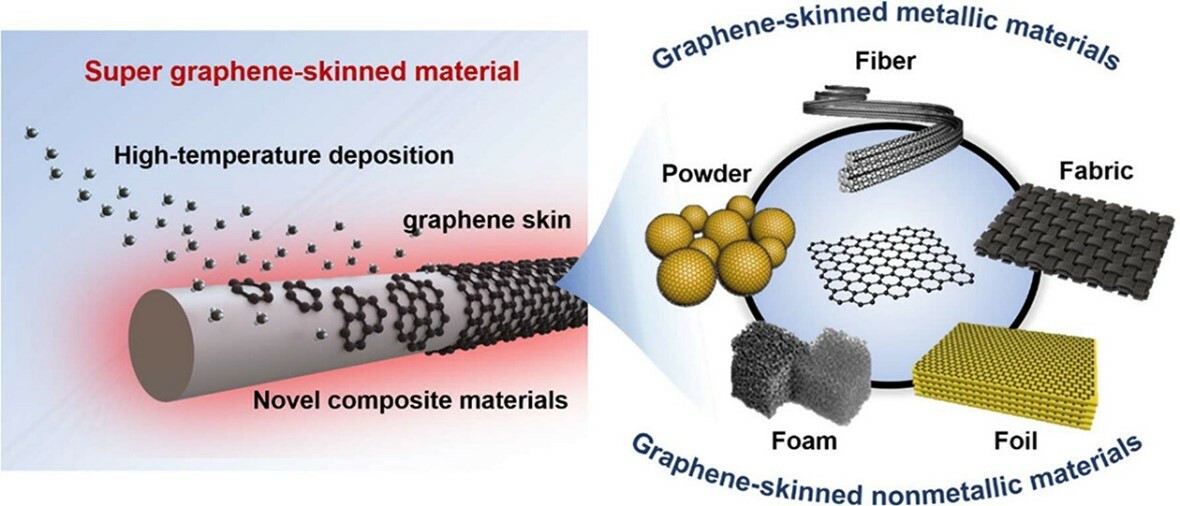

Since graphene was first synthesized, its engineering applications have become a shared focus of attention in both academia and industry. Prof. Zhongfan Liu and Prof. Yue Qi’s group in Beijing Graphene Institute (BGI) and Peking University recently reported the “Super Graphene-Skinned Materials” (ACS Nano 2024, 18, 4617-4623). In an era driven by technological advancements, graphene continues to shine as a star material, and now it’s poised to make an even bigger impact. A groundbreaking concept—super graphene-skinned materials—is redefining the way we integrate graphene into traditional engineering materials, opening doors to applications once thought impossible.

A Material Like No Other

Graphene, the celebrated two-dimensional material, is known for its ultrahigh electrical and thermal conductivity, mechanical strength, and lightweight properties. Historically, its forms have been limited to graphene powder and continuous graphene films. While powder enhances composites, continuous films, produced through chemical vapor deposition (CVD), are prized for their purity and exceptional performance. However, the practical use of graphene films has faced a significant hurdle: peeling and transferring these atomically thin layers from their growth substrates to application-ready materials.

Enter super graphene-skinned materials—a novel solution developed by researchers to overcome these limitations. By depositing graphene films directly onto engineering materials, this innovative approach allows graphene to seamlessly integrate with existing materials, preserving its properties while bypassing the need for complex transfer processes.

Graphene Gets a "Skin"

The concept involves growing continuous graphene films on various engineering substrates through a high-temperature CVD process. This process transforms materials like glass fibers and metal foils into high-performance composites by adding a layer of graphene as a "skin." Unlike traditional graphene coatings that use powders, this technique ensures the graphene retains its original properties, earning the title "super graphene."

For example, graphene-skinned glass fibers showcase excellent electrical and thermal conductivities while maintaining the flexibility and structural integrity of conventional glass fibers. This compatibility means the fibers can be woven, molded, or shaped using existing manufacturing processes, paving the way for scalable, real-world applications.

A Family of Super Materials

Super graphene-skinned materials are not just limited to glass fibers. They encompass a wide range of substrates, including metals like copper and nickel and nonmetals such as silicon carbide and aluminum oxide. These materials can take on various forms—fibers, powders, foils, and even foams—making them versatile building blocks for advanced composites.

The choice of substrate plays a critical role in determining the properties and applications of these materials. For instance, graphene-skinned metallic materials, grown on substrates like copper, exhibit enhanced electrical and thermal performance, making them ideal for electronic and high-current applications. Similarly, nonmetallic carriers, such as alumina or boron nitride, combine graphene's properties with lightweight and high-strength characteristics, promising breakthroughs in aerospace, construction, and more.

Beyond the Surface

The possibilities don’t stop at the initial graphene layer. These materials can undergo post-processing to fine-tune their properties. Technologies like powder metallurgy, additive manufacturing, and composite molding can reshape graphene-skinned materials into bulk structures with tailored thermal, electrical, and mechanical characteristics.

Notably, graphene "skins" can be engineered with varying thicknesses, orientations, and stacking orders to meet specific application needs. Advanced designs, such as vertical graphene nanowalls, further enhance properties like electromagnetic shielding and corrosion resistance.

Challenges on the Horizon

While the potential of super graphene-skinned materials is immense, challenges remain. High-temperature CVD processes can alter the properties of the underlying materials, and mechanical deformation during use can cause cracks in the graphene layer, reducing its effectiveness. Furthermore, achieving uniform graphene growth on complex substrates, especially powders, requires further research and innovation.

Nevertheless, methods like fluidized-bed and bubble-assisted CVD are showing promise in addressing these issues, bringing the concept closer to industrial scalability.

A Bright Future for Industry

The introduction of super graphene-skinned materials is more than just a scientific milestone; it’s a leap toward industrial transformation. By combining graphene’s unparalleled properties with the practicality of conventional materials, these composites offer solutions for everything from energy storage and heat dissipation to structural reinforcement and lightweight designs.

Industries in electronics, aerospace, renewable energy, and construction stand to benefit significantly. Imagine lighter airplanes with graphene-reinforced components, faster electronics with enhanced heat management, and more efficient batteries with superior conductivity—all made possible by super graphene-skinned materials.

Pioneering a New Chapter

As researchers refine the processes for producing and scaling these materials, the impact on technology and industry will only grow. The ability to "skin" traditional materials with graphene not only bridges the gap between laboratory innovation and real-world application but also sets the stage for future breakthroughs.

Super graphene-skinned materials are more than a technical advancement—they are a vision of what’s possible when cutting-edge science meets practical engineering. And in this vision, the world of materials science is poised to enter a super era.

“Super graphene-skinned materials” is an innovative strategy toward graphene practical applications, which will inspire more approaches to achieve the translation of graphene's exceptional properties from atomic-scale structures to macroscopic bulk materials.

Figure 1. Super graphene-skinned materials.

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in