New electrothermal process rapidly removes multiple pollutants in contaminated soils

Published in Electrical & Electronic Engineering

Soil contamination is a pressing global environmental concern that caused by industrial activity, agricultural chemicals, or improper disposal of waste. Multiple pollutant can co-exist in soils, mainly including heavy metals such as mercury, lead, arsenic, and cadmium, as well as organic pollutants like petroleum hydrocarbons, polynuclear aromatic hydrocarbon, and organic solvents. Traditional physical, chemical, and biological processes for soil remediation like soil washing are often slow and lack generality due to the various sources, occurrences, and chemical properties of the pollutants. Multiple approaches are frequently required to address co-contamination of soil by heavy metals and organic pollutants. Even worse, co-contaminants can interfere with or compete to reduce the effectiveness of a particular remediation method. With the rising incidence of co-contaminated soils, it is essential to develop a general, energy-efficient technology to remove multiple pollutants efficiently and rapidly.

Our research group in the chemistry department at Rice University has recently been exploring with a flash Joule heating process, which uses direct electric pulses to heat materials to a high temperature within milliseconds. Different from the indirect heating approaches, the electric heating directs most of its energy into the materials and thus has high energy efficiency. We initially utilized this process to convert various carbon sources into flash graphene (https://doi.org/10.1038/s41586-020-1938-0). With the capability of achieving ultrahigh temperature up to 3000 °C, we demonstrated the evaporative separation and recovery of precious metals from electronic waste for urban mining (https://doi.org/10.1038/s41467-021-26038-9), recycling of rare earth metals from industrial waste streams like coal ashes and red mud (https://doi.org/10.1126/science.289.5488.2295), and purification of coal fly ash for low carbon footprint cement (https://doi.org/10.1038/s44172-023-00062-7).

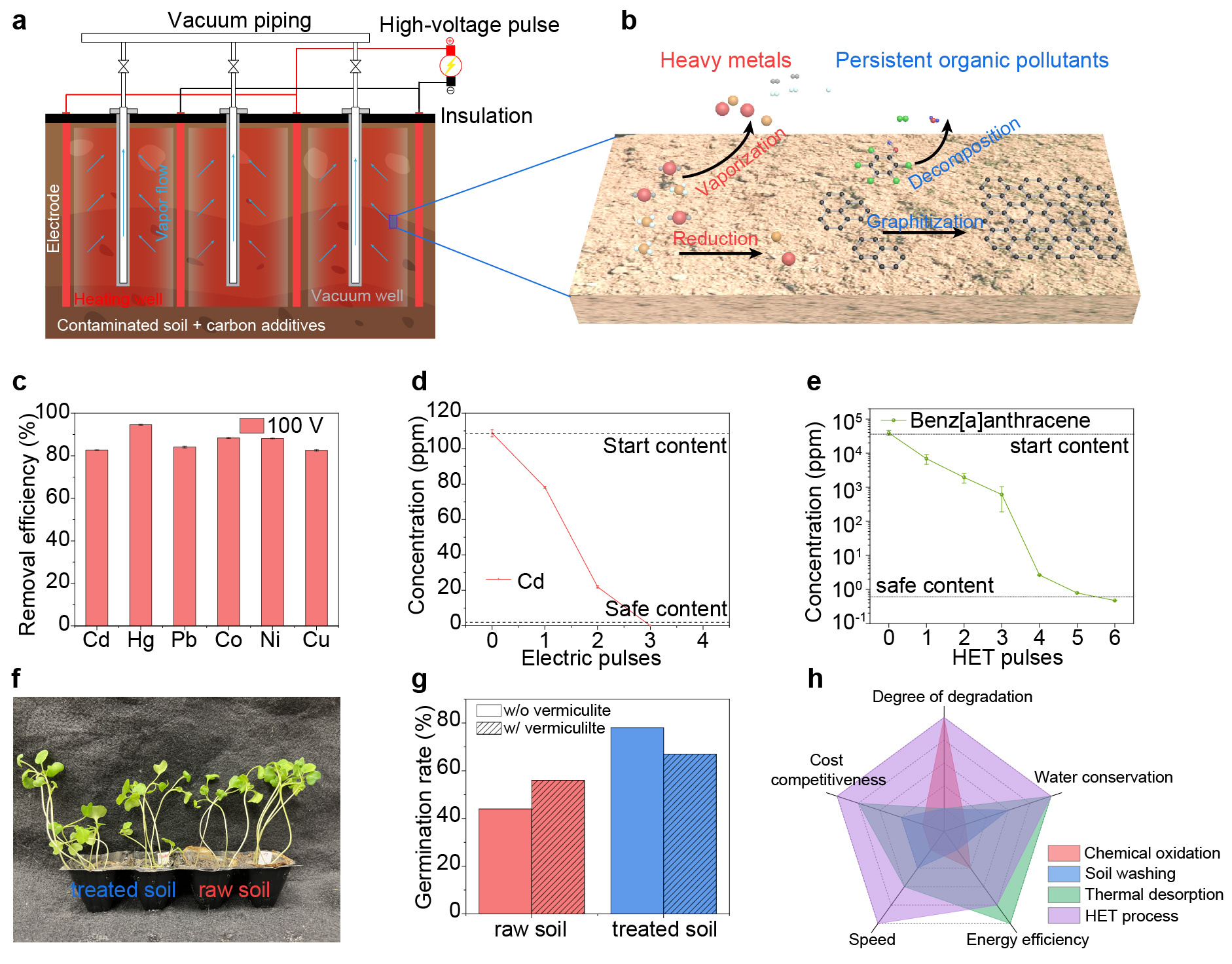

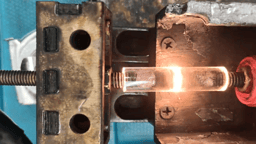

Based on the direct electric heating, we have now invented a high-temperature electrothermal (HET) process to remediate soils contaminated with heavy metals and organic pollutants. In the HET process, dry soil is mixed with conductive additives to ensure good electrical conductivity. A high-voltage pulse input within seconds controllably brings the soil to a typical temperature of >1000 °C as needed (Figure 1a). At this high temperature, heavy metals are carbothermically reduced and vaporized (Figure 1b), and the vapors can then be collected via the vapor extraction pipes (Figure 1a), which are commonly utilized in traditional thermal desorption remediation techniques. The high temperature simultaneously destroys the organic pollutants. For instance, polycyclic aromatic hydrocarbons are carbonized to graphene or graphite (Figure 1b), the most stable form of carbon, which are naturally occurring non-toxic materials or minerals.

We initially tested the process for heavy metal removal at a lab scale. We collected clean soil from the Rice University campus and then co-contaminated the soil by spiking various heavy metal salts, including cadmium, mercury, lead, cobalt, nickel, and copper. At the optimized HET voltage input of 100 volts, the removal efficiencies of all heavy metals were >80% in a single electric pulse, which last only one second (Figure 1c). Unlike some physicochemical adsorption methods that rely on sorbent capacity, the HET process for heavy metal removal has no capacity limit. By increasing the number of electric pulses, heavy metal concentration in soil can be continuously reduced to within safe content levels (Figure 1d). In addition to heavy metals, the HET process can also destroy persistent organic pollutants. To test this, we used the polycyclic aromatic hydrocarbon-contaminated soil as example, with pyrene, fluorene, and benz[a]anthracene as representative compounds. Similarly, the organic pollutants were reduced to within the primary remedial goal after a few electric pulses (Figure 1e).

Figures 1. High-temperature electrothermal (HET) remediation of multi-pollutants in soil. (a) Schematic of the HET process, combined with vacuum extraction well. The vacuum piping and insulation blanket remains standard to known thermal remediation methods, but in the case of HET, the electrodes provide a rapid voltage pulse for electric heating, rather than long-duration heat injection. The soil is premixed in place, with biochar or other conductive carbon to provide sufficient conductivity. (b) Schematic showing the removal of heavy metals by reduction and vaporization, and the removal of persistent organic pollutant (POP) by graphitization for PAH. (c) The removal efficiencies of heavy metals at HET voltage of 100 V. (d) The contents of Cd in soil after repetitive electric pulses. The safe contents are from the standard of California Human Health Screening Levels. (e) The content of benz[a]anthracene in soil varied with repetitive HET pulses. The safe contents denote the preliminary remediation goals. (f) Picture of the growth of broccoli on raw soil and 50% treated soil. (g) Gemination rate of broccoli using raw soil and HET treated soil, with or without vermiculite additive. (i) Comparison of the HET process with other existing soil remediation practices.

We then assessed the soil properties after the HET treatment since they are important for the soil reuse in agriculture. We found that, apart from the removal of contaminants, the morphology, particle size, and mineral constituents of the treated soil changed little by the HET process. We attribute this to its ultrafast heating and cooling rates, as well as short heating duration. We also conducted plant assays using broccoli sprouts to demonstrate the applicability of the HET method for agricultural land remediation. In this case, the treated soil was mixed with raw soil at a weight ratio of 1:1 (Figure 1f). Interestingly, we found that the treated soil showed a 20 to 30% higher germination rates than the raw soil (Figure 1g). This might be attributed to the increased exchangeable nutrients in soil due to the rapid mineralization of soil organic matter in the HET process.

Practical applicability is pivotal for a new technique. Even though we here only demonstrated the HET process in lab scale, we proposed a few strategies to integrate the HET process into industrial upscaling techniques, as well as field facility for on-site remediation with no soil relocation, which will be our next step. With its versatility in remediating multiple pollutants, high degree of pollutant degradation, ultrafast operation speed within seconds to minutes, relatively low energy demand, low overall expense, and zero water usage (Figure 1h), the HET process shows promise for future soil remediation practices, complementing existing thermal desorption and soil washing methods.

Some authors of the paper (left to right): Yi Cheng, James M. Tour, Bing Deng (photo by Gustavo Raskosky)

Follow the Topic

-

Nature Communications

An open access, multidisciplinary journal dedicated to publishing high-quality research in all areas of the biological, health, physical, chemical and Earth sciences.

Related Collections

With Collections, you can get published faster and increase your visibility.

Women's Health

Publishing Model: Hybrid

Deadline: Ongoing

Advances in neurodegenerative diseases

Publishing Model: Hybrid

Deadline: Mar 24, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in