Thermally Drawn Flexible Fiber Sensors: Principles, Materials, Structures, and Applications

Published in Materials

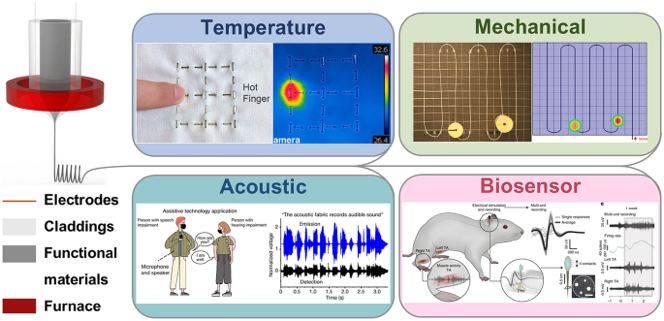

Flexible fiber sensors are essential components of wearable electronics, offering excellent flexibility, biocompatibility, and integration into smart textiles. However, traditional fabrication methods often involve complex procedures and are limited in scalability. Now, researchers from the Institute of Engineering Thermophysics, Chinese Academy of Sciences, led by Prof. Ting Zhang and Prof. Haisheng Chen, have presented a comprehensive review on thermally drawn flexible fiber sensors (TDFSs). This work highlights how the thermal drawing process enables low-cost, large-scale production of multifunctional fiber sensors for a wide range of applications.

Why Thermally Drawn Fiber Sensors Matter

- Scalable Manufacturing: The thermal drawing process allows for rapid, automated production of kilometer-long fibers with integrated functionalities, overcoming the limitations of traditional fiber fabrication methods.

- Multifunctionality: TDFSs can detect various stimuli—including temperature, pressure, strain, chemicals, light, and biological signals—making them ideal for wearable and implantable devices.

- Material and Structural Versatility: The process supports the co-drawing of polymers, metals, and semiconductors into complex microstructures, enabling high-performance sensing capabilities.

Innovative Design and Features

- Thermal Drawing Mechanism: A preform-to-fiber technique where macroscopic preforms are heated and drawn into flexible fibers with embedded functional materials and microstructures.

- Material Selection Criteria: Emphasizes matching thermal and mechanical properties (e.g., glass transition temperature, thermal expansion coefficient) to ensure fiber integrity and performance.

- Sensor Types: Covers a broad spectrum of sensing principles—resistive, capacitive, piezoelectric, triboelectric, photoelectric, and thermoelectric—applied in temperature, acoustic, mechanical, chemical, biological, and optoelectronic sensors.

Applications and Future Outlook

- Wearable Health Monitoring: TDFSs woven into fabrics can monitor body temperature, heart rate, and motion with high sensitivity and comfort.

- Implantable Neural Probes: Flexible, biocompatible fiber probes enable long-term neural recording and stimulation with minimal tissue damage.

- Distributed Sensing: Fibers capable of spatially resolved sensing are used in smart textiles, robotics, and environmental monitoring.

- Challenges and Opportunities: The review outlines key challenges such as material compatibility, structural optimization, and long-term stability. Future research will focus on integrating multiple sensing functions, improving durability, and expanding the material library for broader applications.

This comprehensive review provides a roadmap for the development of next-generation flexible sensors using the thermal drawing process. It underscores the potential of TDFSs to revolutionize wearable technology, biomedical devices, and smart systems. Stay tuned for more innovations from Prof. Ting Zhang and Prof. Haisheng Chen’s team at the Chinese Academy of Sciences!

Follow the Topic

-

Nano-Micro Letters

Nano-Micro Letters is a peer-reviewed, international, interdisciplinary and open-access journal that focus on science, experiments, engineering, technologies and applications of nano- or microscale structure and system in physics, chemistry, biology, material science, and pharmacy.

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in