Towards industry-ready additive manufacturing: AI-enabled closed-loop control for 3D melt electrowriting

Published in Bioengineering & Biotechnology

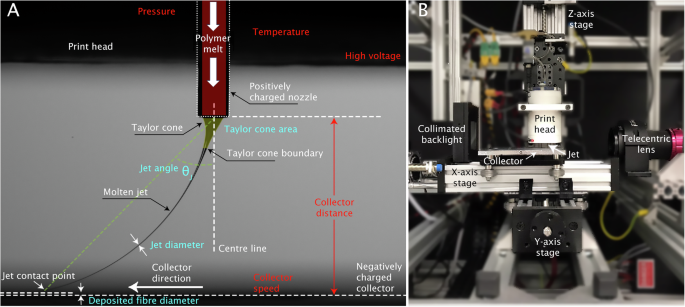

Melt electrowriting (MEW) is a new high-resolution 3D printing technology used in bioengineering, tissue engineering, regenerative medicine, biomaterials science, and soft robotics. The advancement of this technology from early stages (TRLs 1-3) to more advanced stages (above TRLs 5) has faced challenges. These include long experimentation times, low printing speed, poor consistency in results, and dependence on the user for printer operation. These challenges arise because the MEW process is complex and affected by many factors. To solve these problems, we used machine learning (ML) to create a closed-loop process control system for MEW. This system is effective because it monitors the gap between the nozzle and collector, allowing us to use real-time imaging for continuous analysis. We developed an automated method for collecting data that drastically cuts down the experimental time from days to hours. We use a feedforward neural network, optimization techniques, and feedback loop to ensure that printed parts are consistently reproducible. Our work shows that machine learning can automate MEW operations and help create effective closed-loop control in this complex 3D printing technology.

The research team comprised: Dr Pawel Mieszczanek, Distinguished Emeritus Professor Peter Corke, Distinguished Professor W. Hutmacher, from QUT; Professor Courosh Mehanian and Associate Professor Paul D. Dalton from the University of Oregon.

QUT biomedical engineers have developed a new automated method to drastically advance melt electrowriting, a new, high-resolution 3D printing technology used in tissue engineering and regenerative medicine.

First author Dr Pawel Mieszczanek, from the ARC Training Centre in Additive Biomanufacturing at QUT, said the researchers’ method would enable faster advancement of melt electrowetting (MEW) technology. “MEW is a multifaceted 3D printing technology that also has applications in bioengineering, biomaterials science, and soft robotics,” Dr Mieszczanek said. “However, it has faced many challenges from its early stages to its current stage, hampered by long experimentation times, low printing speeds, poor consistency in results, and dependence on the user for printer operation.

“To solve these problems, we used machine learning (ML) to create a closed-loop process control system for MEW. This system is effective because it monitors the fibre flight pass, allowing us to use real-time imaging for continuous analysis.”

Distinguished Professor Dietmar W. Hutmacher, Director of the Max Planck Queensland Centre (MPQC) for the Materials Science of Extracellular Matrices, based at QUT, said the new automated data collection system reduced the experimental time to hours instead of days.

“We use a feedforward neural network, optimization techniques, and feedback loop to ensure that printed parts are consistently reproducible. This work shows that machine learning can automate MEW operations and help create effective closed-loop control in complex 3D printing technology.”

The study, “Towards industry-ready additive manufacturing: AI-enabled closed-loop control for 3D melt electrowriting” was published in Communications Engineering.

Follow the Topic

-

Communications Engineering

A selective open access journal from Nature Portfolio publishing high-quality research, reviews and commentary in all areas of engineering.

Related Collections

With Collections, you can get published faster and increase your visibility.

Applications of magnetic particles in biomedical imaging, diagnostics and therapies

Publishing Model: Open Access

Deadline: May 31, 2026

Integrated Photonics for High-Speed Wireless Communication

Publishing Model: Open Access

Deadline: Mar 31, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in

QUT biomedical engineers have developed a new automated method to drastically advance melt electrowriting, a new, high-resolution 3D printing technology used in tissue engineering and regenerative medicine.

First author Dr Pawel Mieszczanek, from the ARC Training Centre in Additive Biomanufacturing at QUT, said the researchers’ method would enable faster advancement of melt electrowetting (MEW) technology.

“MEW is a multifaceted 3D printing technology that also has applications in bioengineering, biomaterials science, and soft robotics,” Dr Mieszczanek said.

“However, it has faced many challenges from its early stages to its current stage, hampered by long experimentation times, low printing speeds, poor consistency in results, and dependence on the user for printer operation.

“To solve these problems, we used machine learning (ML) to create a closed-loop process control system for MEW.

“This system is effective because it monitors the fibre flight pass, allowing us to use real-time imaging for continuous analysis.”

Distinguished Professor Dietmar W. Hutmacher, Director of the Max Planck Queensland Centre (MPQC) for the Materials Science of Extracellular Matrices, based at QUT, said the new automated data collection system reduced the experimental time to hours instead of days.

“We use a feedforward neural network, optimization techniques, and feedback loop to ensure that printed parts are consistently reproducible.

“This work shows that machine learning can automate MEW operations and help create effective closed-loop control in complex 3D printing technology.”

The research team comprised: Dr Pawel Mieszczanek, Distinguished Emeritus Professor Peter Corke, Distinguished Professor W. Hutmacher, from QUT; Professor Courosh Mehanian and Associate Professor Paul D. Dalton from the University of Oregon.

The study, “Towards industry-ready additive manufacturing: AI-enabled closed-loop control for 3D melt electrowriting” was published in Communications Engineering.