Washable heat-resistant and inkjet-printed devices on cotton fabric for wearable applications

Published in Healthcare & Nursing and Materials

With the advancement of wearable electronic devices, electronic textiles (e-textiles), which impart electronic functionalities directly to fabrics, have emerged as a key enabling technology for various wearable platforms, including healthcare monitoring and IoT-based sensor networks. However, conventional e-textile fabrication methods have faced significant limitations: thick coating layers reduce the inherent breathability and comfort of the fabric, and the low bonding strength between the coated conductive material and the fabric leads to a rapid deterioration of electrical conductivity under external environmental conditions.

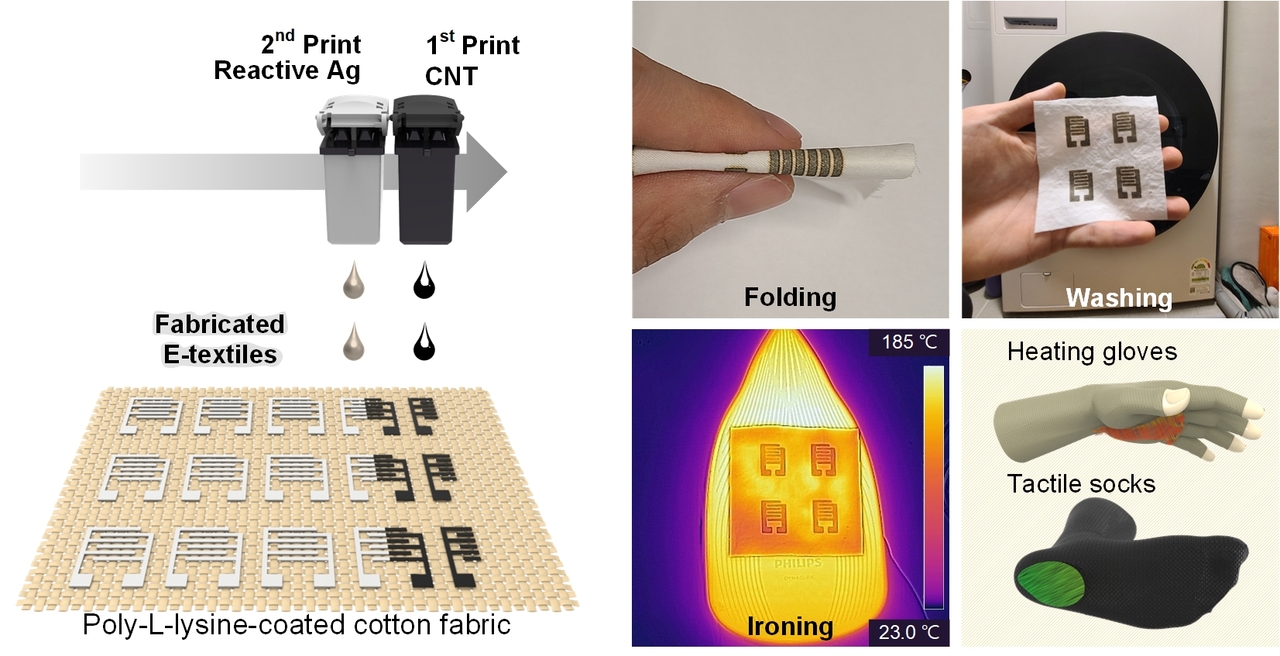

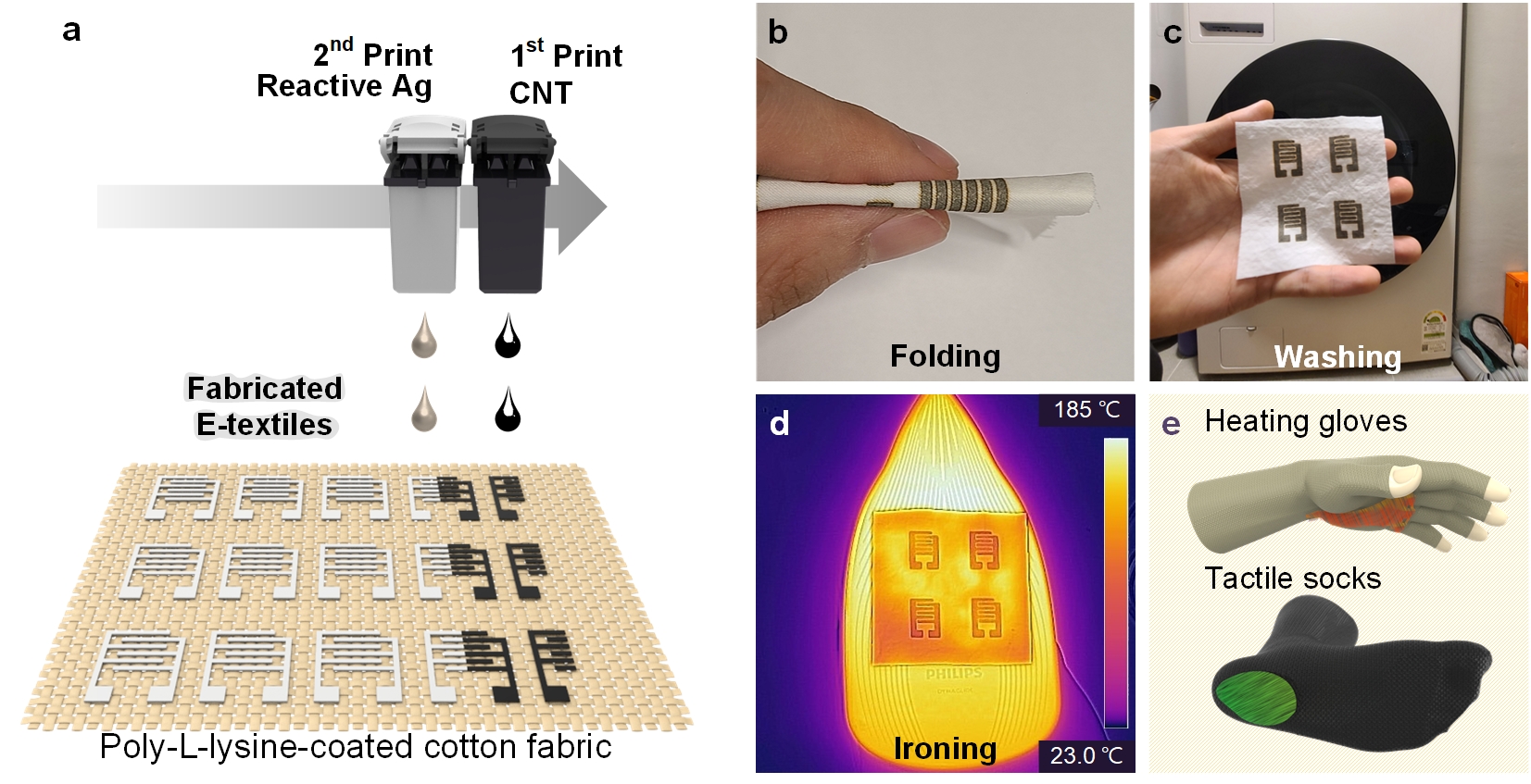

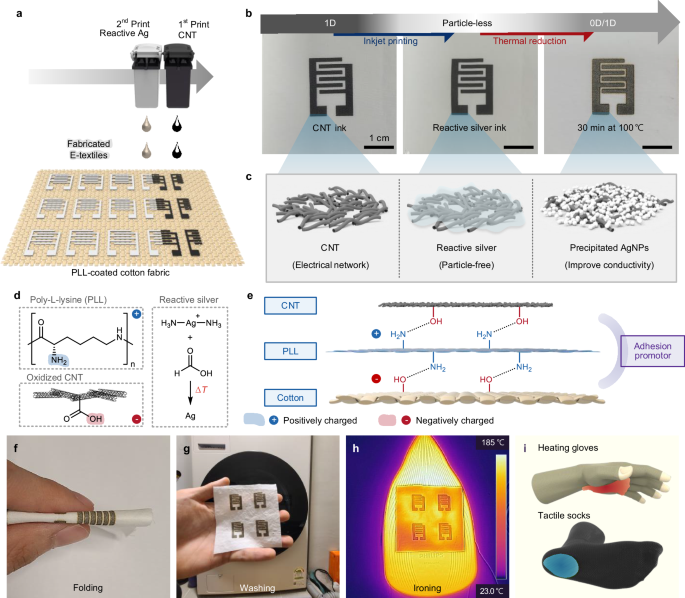

To address these challenges, we developed cotton-based e-textiles by precisely inkjet-printing carbon nanotube (CNT) inks and particle-free reactive silver inks onto the fabric, enabling high conductivity while maintaining breathability and flexibility. The fabricated e-textiles were successfully applied to high-sensitivity pressure sensors and efficient heating devices, demonstrating their potential for wearable devices. Notably, inkjet printing enables easy integration of customized patterns and functions, and since it can be carried out using a standard household inkjet printer, the process has strong applicability for both personal uses and small-scale manufacturing environments.

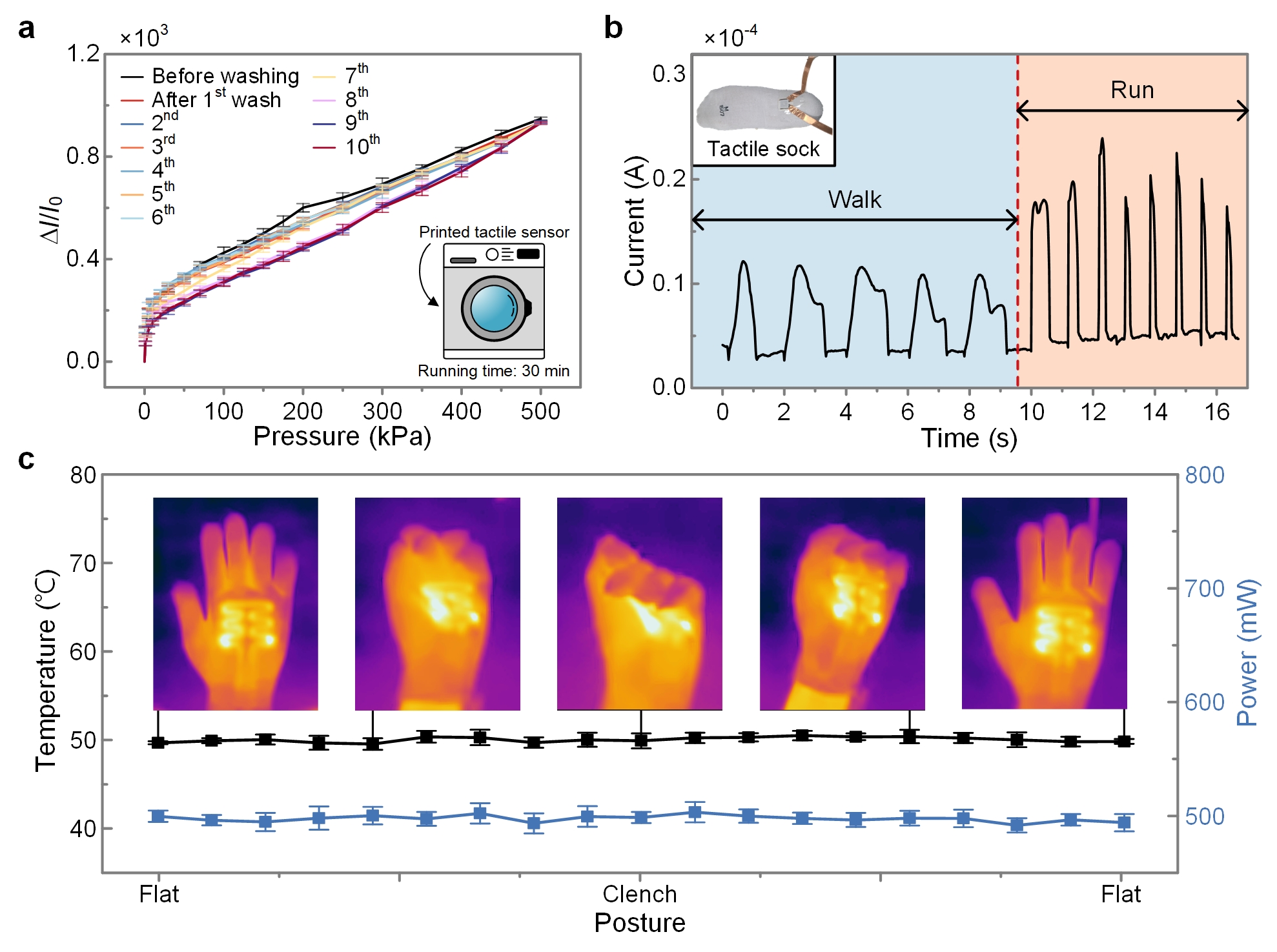

In addition, by treating the fabric with poly-L-lysine, a positively charged and biocompatible polymer, we promoted strong ionic bonding between the negatively charged conductive nanomaterials and the cotton fibers, thereby overcoming the durability issues of conventional e-textiles. The fabricated textiles maintained their conductivity even under mechanical deformation, such as bending and twisting, and retained stable performance even after 10 household washing cycles. This represents a significant improvement compared to conventional e-textiles, which are either non-washable or require protective coatings that reduce breathability to achieve washability.

The fabricated pressure sensor was constructed by inkjet-printing CNT and reactive silver inks to form the electrode layer, followed by separately printing a CNT layer as the sensing element. These layers were then placed face-to-face. When pressure is applied, the actual contact area between the sensing and electrode layers changes, altering the electrical resistance and enabling pressure detection. The rough surface structure of cotton fabrics amplifies these contact-area variations, allowing the sensor to detect a wide pressure range, from subtle signals such as human breathing to large forces such as body weight. This capability was demonstrated by integrating the sensor into garments for monitoring human motion and mechanical pressure.

Conventional commercial heating garments are typically produced by attaching metallic wires or film heaters onto fabrics, which results in bulky, uncomfortable designs with limited placement and design options. In contrast, our e-textile heating devices directly integrate heating functionality into the fabric itself, producing thin and flexible heaters that remain operational even after repeated washing and mechanical deformation. Furthermore, the use of inkjet printing enables freeform integration across garments, opening possibilities for personalized heating patches and wearable thermotherapy devices that go beyond the constraints of existing products.

This study demonstrates a washable cotton-based e-textile fabrication technology that maintains comfort while enabling integration into functional devices such as sensors and heaters. Specifically, it is the first to demonstrate an e-textile that maintains the inherent properties of the fabric while also exhibiting excellent washability. Moreover, the proposed surface treatment and inkjet-printing process can be readily extended to other natural and synthetic fabrics, broadening the scope of e-textile applications. The versatility of this technology paves the way for commercialization in wearable fields such as healthcare monitoring garments, rehabilitation devices, and smart sports equipment.

Read the full paper here: https://doi.org/10.1038/s41467-025-63636-3

Follow the Topic

-

Nature Communications

An open access, multidisciplinary journal dedicated to publishing high-quality research in all areas of the biological, health, physical, chemical and Earth sciences.

Related Collections

With Collections, you can get published faster and increase your visibility.

Women's Health

Publishing Model: Hybrid

Deadline: Ongoing

Advances in neurodegenerative diseases

Publishing Model: Hybrid

Deadline: Mar 24, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in