Amazing ultra-high room temperature coercivity

Published in Physics

We have enabled SmCo4B alloy to exhibit surprisingly room temperature coercivity and excellent comprehensive magnetic properties. In previous studies, scholars improved the actual coercivity and magnetization of SmCo4B alloys by doping elements. Although some progress has been made in improving magnetic performance, there is still much confusion in understanding their phase transition, microstructure evolution, and magnetic enhancement mechanism. In recent studies, we found that Ni can effectively stabilize the crystal structure of the Sm(Co, Fe)5 phase. Therefore, we designed and prepared Sm(Co, Fe, Ni)4B alloys with excellent hard magnetic properties by adjusting the Fe, Co, Ni content and revealed the relationship between the phase composition, microstructure, and magnetic properties. These results can provide a new theoretical basis and experimental support for developing high-performance SmCo4B-based magnets.

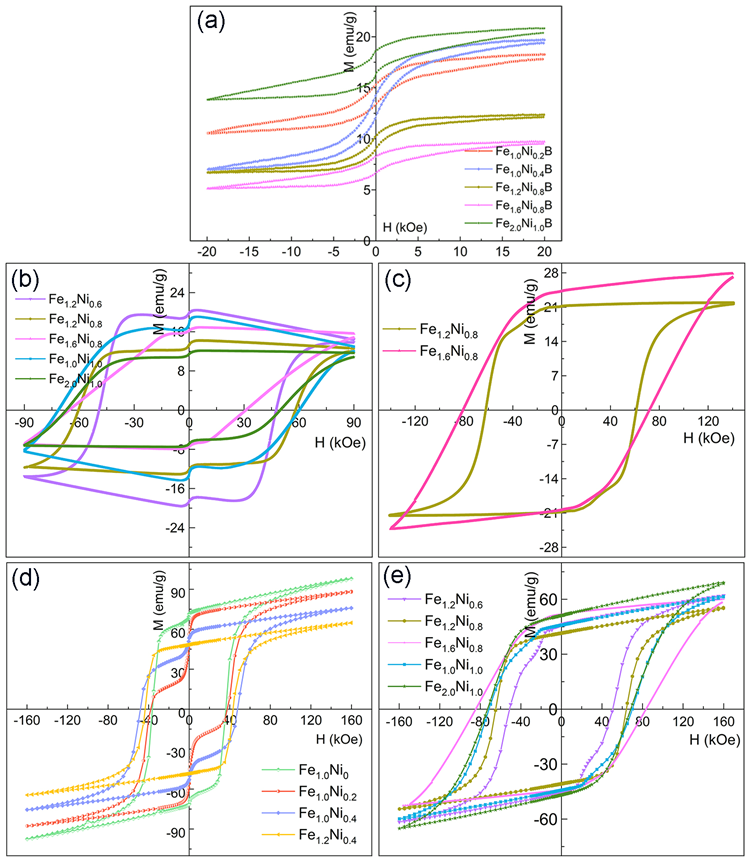

We overcame multiple difficulties and obtained multiple surprises. For example, we initially used a vibrating sample magnetometer to measure the magnetic properties of annealed SmCo4–x–yFexNiyB (FexNiy, x = 1.0−2.0; y = 0−1.0) ribbons at 20 kOe field, and observed that some of the ribbons exhibited much higher coercivity than expected, as shown in Fig. 1a. These hysteresis loops are so strange that they only pass through quadrants 1 and 2. To further explain the experimental results, we used a physical property measurement system (PPMS) to re-measure the samples under a 90 kOe magnetic field, and the results are shown in Fig. 1b. We observed other interesting phenomena, such as the hysteresis loops still not closing in the first quadrant, the magnetization at a maximum magnetic field of 90 kOe being lower than the remanence, and the appearance of a step in the second quadrant. We speculate that these phenomena may still be due to the magnetic field being too small to test. So, we re-measured the Fe1.2Ni0.8 ribbons with step characteristics in the second quadrant and the Fe1.6Ni0.8 ribbons with a significantly biased hysteresis loop at a higher magnetic field of 140 kOe, as shown in Fig. 1c. It can be observed that the step features are no longer noticeable, the phenomenon of magnetization being lower than remanence under maximum magnetic field is reduced or eliminated, and the hysteresis loops become more symmetrical, which confirms our inference that the test magnetic field is too small. Even more surprising is that the Fe1.6Ni0.8 ribbons achieved a high coercivity of up to 81.2 kOe under an applied field of 140 kOe. To ensure the accuracy and reliability of the data, we re-measured all samples under a magnetic field of 160 kOe, as shown in Fig. 1d-e. SmCo4B ribbons doped with Fe and Ni achieved ultra-high room temperature coercivity of 36.3-84.3 kOe and high saturation magnetization of 55.4-98.0 emu/g. These findings provide new ideas for subsequent magnet research and demonstrate the significant impact of co-doping Fe and Ni on the magnetic properties of SmCo4B alloy.

Our findings may have profound implications for developing next-generation permanent magnet materials. Through in-depth research and optimization of SmCo4B material, we have revealed the enormous potential of doping Fe, Ni, and other alloy elements to enhance magnetic properties, laying the foundation for developing magnetic materials with higher magnetic energy products. In addition, this study provides an important technological path and development direction for the industrialization research of SmCo4B magnets in the future. Firstly, subsequent research can continue to focus on further optimizing doping elements, finely controlling grain structure and orientation, and achieving anisotropic SmCo4B-based magnets. This will improve the performance of materials and provide more reliable magnetic materials for manufacturing electric vehicles, wind power generation, and high-performance motors. Secondly, this SmCo4B materials with high coercivity can be combined with other magnetic materials with high magnetization (such as Nd-Fe-B) to fully leverage the dual advantages of high coercivity and high magnetization of both materials, thereby developing composite magnets with even better performance. By further exploring these research directions, our findings will drive the industrialization process of SmCo4B magnets and open up broader prospects for the application of high-performance permanent magnet materials.

Fig. 1 Hysteresis loops measured under different magnetic field

Follow the Topic

-

Nature Communications

An open access, multidisciplinary journal dedicated to publishing high-quality research in all areas of the biological, health, physical, chemical and Earth sciences.

Related Collections

With Collections, you can get published faster and increase your visibility.

Women's Health

Publishing Model: Hybrid

Deadline: Ongoing

Advances in neurodegenerative diseases

Publishing Model: Hybrid

Deadline: Mar 24, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in