An In-Silico Platform for the Multifunctional Design of 3D-Printed Conductive Components

Published in Materials and Mathematical & Computational Engineering Applications

The integration of multifunctional properties in engineered materials is a growing frontier, particularly in additive manufacturing. Conductive thermoplastics, fabricated via filament extrusion methods, offer exciting potential due to their ability to conduct electrical signals while providing structural support. However, the choice of material composition and printing parameters determines the mesostructure of the component (e.g. filament adhesion and void distribution), in turn influencing the electric resistivity and mechanical properties.

A collaborative research team from Universidad Carlos III de Madrid (Spain), Imperial College London (UK), University of Oxford (UK), and BCMaterials (Spain) has developed a multi-scale computational framework to predict and optimize the thermo-electro-mechanical behavior of 3D-printed conductive polymers. This work, validated by extensive experiments, provides a robust methodology to bridge the gap between mesoscopic and macroscopic multifunctional responses in conductive components.

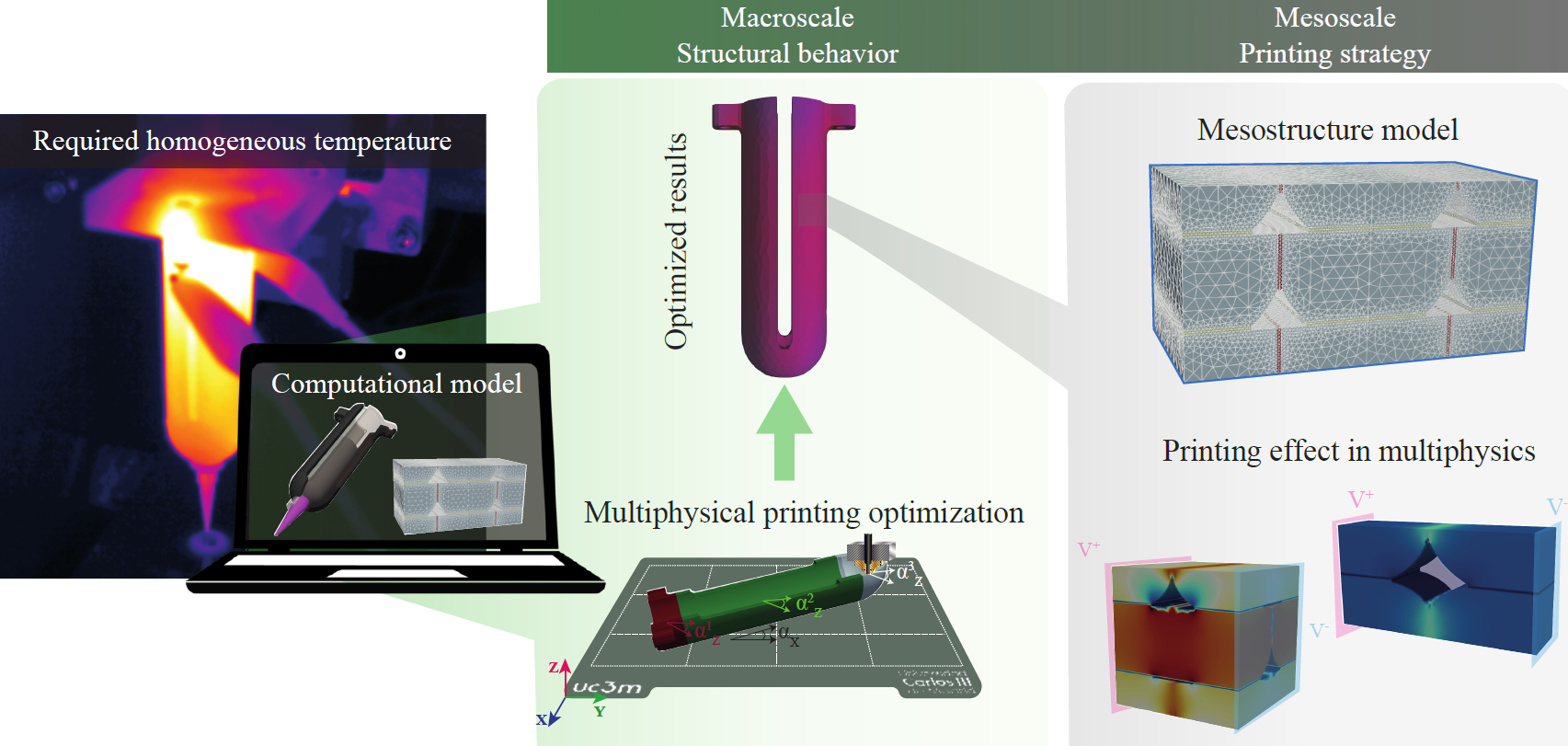

To characterize the multifunctional performance of these materials, the researchers conducted a series of experimental tests on 3D-printed conductive polymer samples with different printing orientations (i.e. longitudinal, transverse, and oblique). These tests isolated and analyzed individual interactions between electrical, thermal, and mechanical properties. The results demonstrated that printing parameters significantly influence conductivity and mechanical response, with longitudinally printed samples exhibiting superior conductivity and mechanical strength compared to transverse configurations, where inter-filament adhesion and voids hinder performance.

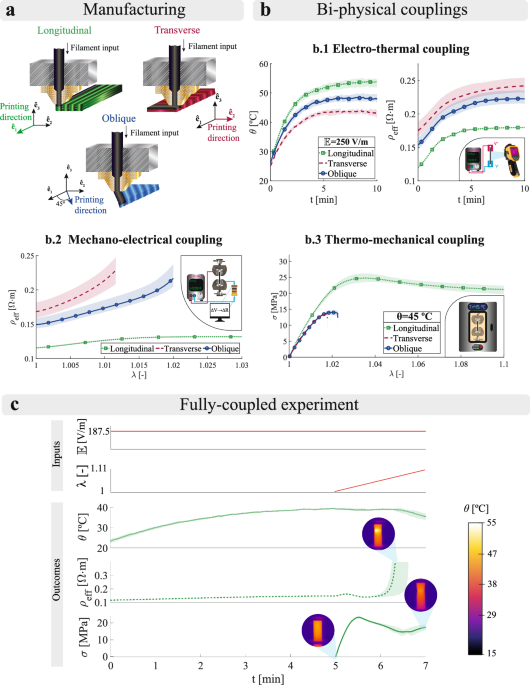

To provide designing tools that allow for taking advantage of these mechanistic insights, the authors developed an in-silico platform that models conductive polymer behavior at multiple scales. A full-field homogenization framework was used to analyze how mesostructural features impact the material response, while a macroscopic continuum model was designed to simulate real-world boundary conditions. This computational approach uncovered key insights, such as how filament adhesion zones affect electrical conductivity and how printing parameters (e.g., layer height, width, and orientation) modulate material performance.

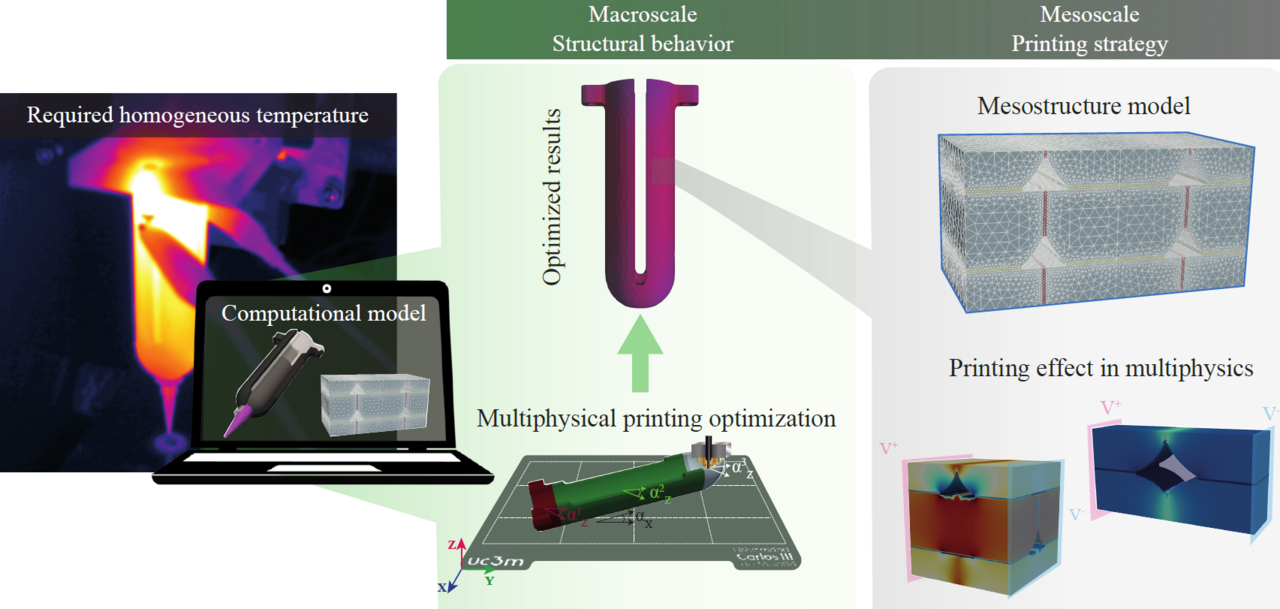

By leveraging this platform, the team designed a functional application: an electro-heatable 3D-printed cartridge for a Direct Ink Writing (DIW) printer (Figure 1). The optimized cartridge enables controlled temperature modulation via Joule heating, ensuring uniform heating distribution and improving ink printability. This proof-of-concept highlights the potential of computational tools in optimizing 3D-printed multifunctional components, paving the way for tailored material design in fields such as soft robotics, bioengineering, and smart electronics.

Figure 1: Computational framework to optimize the design and manufacture of multifunctional structures. The framework connects the influence of printing parameters on the mesostructure of the components, providing how these characteristics scale up to the homogenized macroscopic behavior. By using optimization approaches that consider these effects at both scales, the platform provides the optimal strategy to print multifunctional structures based on a desired thermo-electro-mechanical performance.

More details are provided in the original version of the manuscript: https://doi.org/10.1038/s41467-025-56707-y

Javier Crespo-Miguel, Sergio Lucarini, Sara Garzon-Hernandez, Angel Arias, Emilio Martínez-Pañeda, Daniel Garcia-Gonzalez, In-silico platform for the multifunctional design of 3D printed conductive components. Nat. Commun 16: 1359 (2025).

Follow the Topic

-

Nature Communications

An open access, multidisciplinary journal dedicated to publishing high-quality research in all areas of the biological, health, physical, chemical and Earth sciences.

Related Collections

With Collections, you can get published faster and increase your visibility.

Women's Health

Publishing Model: Hybrid

Deadline: Ongoing

Advances in neurodegenerative diseases

Publishing Model: Hybrid

Deadline: Mar 24, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in