Data-Driven Infrastructure: How Machine Learning Predicts Water Pipeline Failures to Save Resources and Reduce Costs

Published in Earth & Environment, Computational Sciences, and Mathematics

The Growing Problem with Our Water Infrastructure

Across the world, water systems are struggling. In the U.S. alone, water main breaks spill about 2 trillion gallons of treated water each year—imagine the volume of wasted resources and expenses associated with that kind of loss. As pipes age, they’re more likely to break, leak, or burst, leading to costly repairs, water loss, and even risks to public health.

Given the global need to conserve water and reduce infrastructure costs, it’s more crucial than ever to find ways to identify potential failures before they happen. Predictive maintenance, using advanced data analysis and machine learning (ML), is a powerful tool that’s stepping up to help water management agencies move from reactive to proactive. My recent study, Employing Machine Learning in Water Infrastructure Management: Predicting Pipeline Failures for Improved Maintenance and Sustainable Operations, dives into how ML can do exactly that.

Why Machine Learning Matters for Water Systems

Predicting which pipes will fail and when isn’t as straightforward as it sounds. Every city’s water infrastructure has unique variables like pipe age, material, and previous maintenance records, making it hard to forecast problems with a one-size-fits-all approach. Historically, water agencies have relied on reactive approaches—fixing pipes when they fail, rather than before. But this is expensive, disruptive, and often too late to prevent damage or waste.

Machine learning offers an alternative. By training algorithms on past data, we can teach models to predict potential failures and help utilities target maintenance where it’s most needed. This means fewer emergency repairs, less water loss, and greater resilience in our aging water systems.

What the Study Found

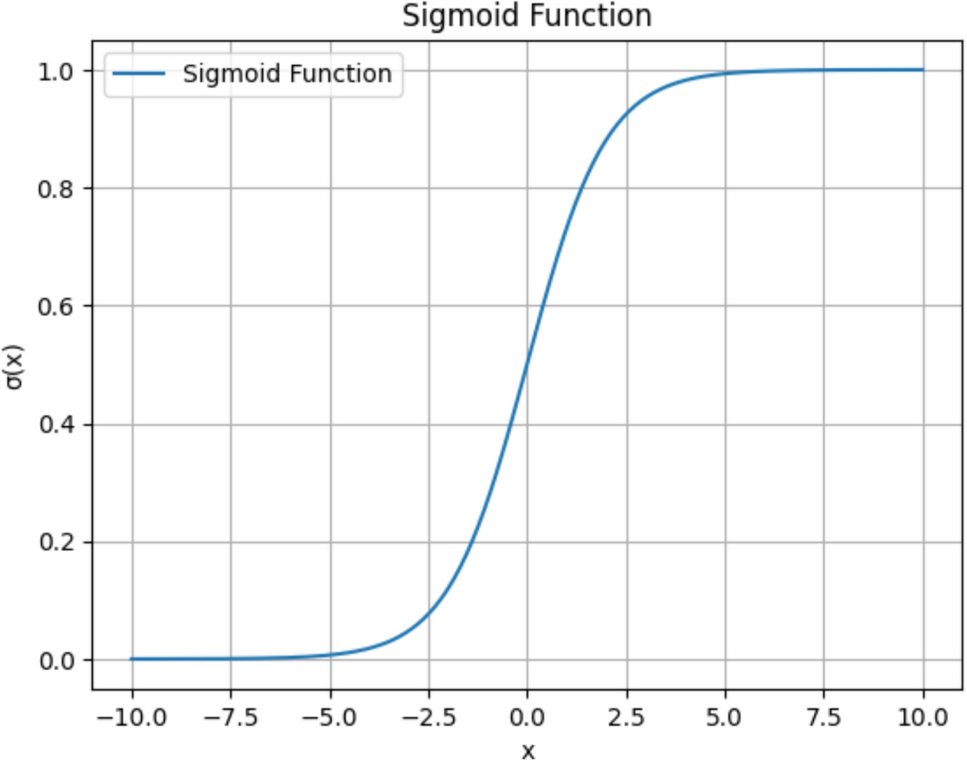

In our study, we tested two popular machine learning models—XGBoost and logistic regression—on a large dataset collected from 2015 to 2022, including variables like pipe material, diameter, and maintenance history. Here’s what we found:

-

XGBoost: This gradient-boosting model was the standout performer, especially in terms of recall, which is crucial in accurately identifying potential failures. The higher the recall, the better we are at catching real failures and avoiding the costs and disruptions of unexpected breaks. In our study, XGBoost scored a recall of 0.795, higher than the 0.683 scored by logistic regression.

-

Logistic Regression: While this simpler model did slightly better on precision, meaning it had fewer false alarms, it couldn’t match XGBoost in identifying the failures we were trying to catch. Overall, XGBoost proved to be more balanced and effective.

What these results show is that by applying the right ML model, water agencies can have a reliable early-warning system, predicting failures before they happen and helping to cut down on both costs and wasted resources.

Real-World Impact

Imagine if cities could prioritize their maintenance based on data-driven predictions instead of guesswork. Predictive maintenance like this could be transformative:

-

Cost Savings: Emergency repairs are expensive, often costing multiple times what planned maintenance would. Knowing which pipes are at risk lets agencies schedule maintenance before it’s too late, helping save money.

-

Water Conservation: The leaks we prevent translate directly into water savings. This is especially crucial in water-scarce regions where every drop counts. Reducing water loss supports global sustainability efforts and conserves precious resources.

-

Protecting Public Health and the Environment: Pipeline breaks can lead to water contamination, impacting nearby soil and water bodies. By reducing these incidents, we protect both public health and the surrounding ecosystems.

Bridging the Gap

One of the biggest challenges in water management is affordability, especially for smaller utilities or cities with older systems. Many high-tech leak detection solutions—like acoustic sensors or fiber optics—can be effective, but they’re expensive and complex to implement. The beauty of our ML approach is that it doesn’t require any specialized hardware. Instead, it leverages data utilities already have: operational records, historical maintenance logs, and pipe attributes.

By analyzing this data with advanced ML models, utilities get the benefit of predictive maintenance without having to invest in costly equipment. This makes predictive analytics a scalable, budget-friendly solution for a wide range of municipalities.

How Predictive Maintenance is Changing the Game for Infrastructure

The field of infrastructure management is ripe for transformation through data and machine learning. Many cities and agencies face limited budgets, aging infrastructure, and an urgent need to reduce their environmental impact. Predictive models like the one we developed offer a path forward, making maintenance more efficient, cost-effective, and sustainable.

This study is just one example of what’s possible. As predictive technology becomes more accessible, I believe we’ll see a shift from reactive to proactive maintenance strategies across not only water systems but other areas like electricity grids, road networks, and public transportation. The potential savings—in both money and resources—are huge.

Next Steps and the Future of Predictive Maintenance

In the coming years, as IoT devices become more common and real-time data becomes more available, these models will only become more accurate. We could soon be looking at predictive systems that integrate real-time monitoring data with historical records to give cities the power to predict and prevent failures with even greater accuracy.

In the meantime, our study lays the groundwork for what can be done with the data already at hand. Water utilities that adopt predictive maintenance now will be on the cutting edge, setting the standard for efficient, resilient infrastructure management.

Shaping a More Resilient, Sustainable Future

With water scarcity on the rise and infrastructure under strain, we’re at a turning point. Embracing machine learning in water infrastructure management allows us to address these challenges head-on, offering a pathway to smarter, more sustainable systems. By preventing pipeline failures before they happen, we not only save money and resources but also protect our communities and ecosystems from preventable harm.

If you’re interested in the details of the study, the specific models, or the potential applications, check out the full paper on Springer Nature Communities. Let’s start the conversation on how we can use data-driven strategies to shape a better future for our infrastructure and our planet.

Follow the Topic

-

Industrial Artificial Intelligence

This journal focuses research on AI applications in virtually all industrial processes.

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in