Desert Power: Aloe Vera’s Role in the Future of Cultivated Meat

Published in Research Data and Agricultural & Food Science

Explore the Research

Cultivation of bovine lipid chunks on Aloe vera scaffolds

npj Science of Food - Cultivation of bovine lipid chunks on Aloe vera scaffolds

To Meat or Not to Meat

Meat is delicious. Whether it’s crispy bacon in the morning, a quick burger on the go, or a perfectly seared steak, we just can’t get enough of it. But this indulgence comes at a cost - a double-edged sword. The environmental impact of meat production is well-documented (Levi et al., 2022).

Six years ago, while wandering the world in search of an epiphany (or at least a clue about what to do with my life), I stumbled upon a video of an Israeli start up called Aleph Farms growing meat in “Zero G” onboard the international space station (Aleph-Zaro). I was flabbergasted. Was this real? Could I really ‘kill two birds with one stone’— except, you know, without actually killing any birds?

That moment sent me down a six-year rabbit hole into academia. For my master’s thesis, under the guidance of Dr. Sharon Schlesinger, we decided to screen plant-based materials as potential scaffolds for cultured meat production. This screening mission was funded by the Good Food Institute and the Israeli Ministry of Science, so no ingredient was safe—rice puffed and starchy (Gome et al., 2024a), watermelon - meaty and red, and even chickpea protein isolates—if it was edible and plant based, it became my next lab rat.

A Match Made in Cultured Meat Heaven

Then, during a lunch break, inspiration struck in the most unexpected way. Dr. Gilad Gome came to the lab with a bottle of flavored water with aloe vera chunks. After taking a sip, he casually said, “You know, this could be a great scaffold.”

That single comment spiraled into an entire conversation about aloe vera’s properties. And just like that, an idea was born.

After attempting to use the aloe vera from the bottle with some success, Gilad contacted Shula Shaham (Just Aloe, Ein-yahav) a farmer that cultivates Aloe vera in the Israeli desert. Shula was happy to hear from us and to our request, she generously had some fresh leaves delivered to us and we started to work.

With Gilad’s’ laser printed macrofluidic single-use bioreactors (MSUB, Gome et al., 2024b) - a clever system that allows rapid prototyping and could cut the costs of custom bioreactors - and our obsession with finding the perfect plant-based scaffold, we had the perfect setup. We explored aloe vera as a scaffold for cultured meat and tailored the MSUB to fit the needs.

The Invention of the First Meat That’s Also a Skincare Product

Our journey began with a lot of “playing with food” - what didn’t we do to that poor aloe vera? I filleted it, baked it, fried it… you name it. But after countless failed attempts, we finally developed a working protocol: filleting, autoclaving, and lyophilizing the aloe vera to transform it into the perfect plant-based scaffold for cultured meat.

As expected, bringing aloe vera from the world of cosmetics and beverages into the realm of cultured meat wasn’t exactly smooth sailing. But challenges only made the process more exciting.

One of the main reasons aloe vera caught our attention was its parenchymal structure. This inner gel-like tissue is rich in cellulose, a polymer already used in tissue engineering (Bar-Shai et al., 2021; Darzi et al., 2021). But what really made it special was its porous nature and its structural integrity after the preparation process - it could absorb and retain large amounts of liquid, creating an environment that mimicked the extracellular matrix and supported mammalian cell growth.

It was as if aloe vera had unknowingly been waiting for its moment to shine in cultured meat research.

Meat’s First Steps into the Real World

With a working scaffold in place, it was time for the real challenge - scaling up and proving its differentiation capabilities. Developing a protocol to differentiate mammalian stem cells happily growing in our scaffold into the adipogenesis pathway.

More importantly, we needed to grow the scaffold under MSUB conditions, a system designed to provide ideal airflow using filtered air pumps. The goal was to ensure enough air and sufficient agitation to evenly distribute nutrients while keeping the scaffold structure intact.

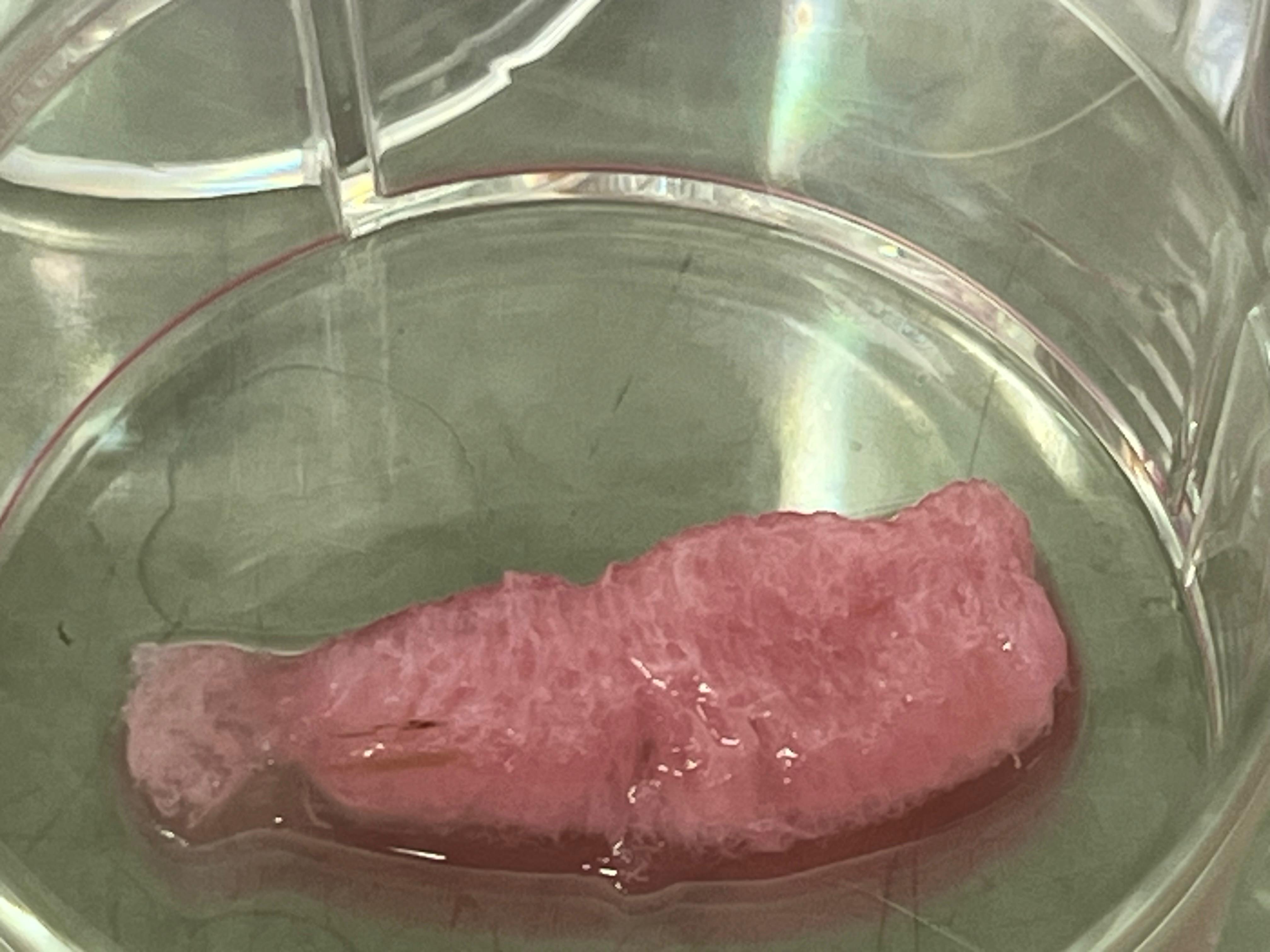

And it worked. We successfully differentiated the scaffold with mammalian stem cells, leading to the formation of lipid droplets under MSUB conditions—or, as we like to call them, “Lipid Chunks.”

It Takes a Lab to Raise a Stem Cell

As you probably know, if you work in stem cell research, mammalian stem cells are the divas of the lab—spoiled little creatures that demand constant attention. They don’t take weekends off, they don’t respect your sleep schedule, and when they’re unhappy, they rarely tell you why.

This journey wouldn’t have been possible without my amazing peers in Dr. Sharon Schlesinger’s lab, who helped with cell maintenance and always had creative ideas when things didn’t go as planned. Most of all, I wish to thank my colleague and collaborator, Dr. Gilad Gome. Working with him was like white-water rafting through a river of creativity and innovation, where every turn brought a new idea, and paddling back to reality was hardly an option. Special thanks also to Dr. Ivana Ribarski, our lab manager - because, let’s be honest, finding things in the lab is not exactly my strongest suit. No matter how many times I forget where something is, Ivana always knows.

And, of course, nothing would have been possible without the guidance and support of Dr. Sharon Schlesinger and Prof. Oded Shoseyov, who helped turn this wild idea into reality—the dream of making affordable cultured meat.

What’s Next? The Future of Aloe Vera Meat

Now that we’ve proven aloe vera works as a scaffold, the next challenge is optimizing it for larger-scale production. How can we make it even more cost-effective? Will it support other types of cultured tissues, beyond fat?

There’s also the question of public perception. When people hear about aloe vera meat, their first reaction is usually "Wait… you mean the stuff in my sunscreen?" But once they see the science, they start to believe in it too.

While there’s still a long way to go, one thing is clear: The future of meat is actually a plant.

References:

Bar-Shai, N., Sharabani-Yosef, O., Zollmann, M., Lesman, A., & Golberg, A. (2021). Seaweed cellulose scaffolds derived from green macroalgae for tissue engineering. Scientific Reports, 11(1), 11843. https://doi.org/10.1038/s41598-021-90903-2

Darzi, S., Paul, K., Leitan, S., Werkmeister, J. A., & Mukherjee, S. (2021). Immunobiology and Application of Aloe vera-Based Scaffolds in Tissue Engineering. International Journal of Molecular Sciences, 22(4), 1708. https://doi.org/10.3390/ijms22041708

Gome, G., Chak, B., Tawil, S., Shpatz, D., Giron, J., Brajzblat, I., Weizman, C., Grishko, A., Schlesinger, S., & Shoseyov, O. (2024a). Cultivation of Bovine Mesenchymal Stem Cells on Plant-Based Scaffolds in a Macrofluidic Single-Use Bioreactor for Cultured Meat. Foods, 13(9), 1361. https://doi.org/10.3390/foods13091361

Gome, G., Benny, O., Shoseyov, O., & Giron, J. (2024b). Design Principles for Laser-Printed Macrofluidics. Inventions, 9(4), 68. https://doi.org/10.3390/inventions9040068

Levi, S., Yen, F.-C., Baruch, L., & Machluf, M. (2022). Scaffolding technologies for the engineering of cultured meat: Towards a safe, sustainable, and scalable production. Trends in Food Science & Technology, 126, 13–25. https://doi.org/10.1016/j.tifs.2022.05.011

Follow the Topic

-

npj Science of Food

This journal aims to advance understanding of all aspects of the ‘One Health’ approach to the food–human health nexus, and promote research related to the United Nations sustainable development goals.

Related Collections

With Collections, you can get published faster and increase your visibility.

The future of palm oil and palm oil product quality, safety and integrity in food technology

Publishing Model: Open Access

Deadline: Feb 24, 2026

Nutrition for muscle and immune health in aging

Publishing Model: Open Access

Deadline: Aug 24, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in