Ion-pair Membrane based electrochemical hydrogen pumps for hydrogen purification and compression.

Published in Chemistry

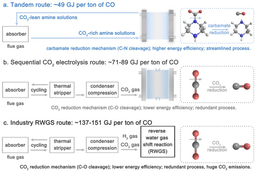

Objective: High temperature polymer electrolyte membrane electrochemical hydrogen pumps (HT-PEM EHPs) offer a promising solution to transport and distribute hydrogen through blending with existing natural gas pipeline network. These EHPs can separate and compress hydrogen from dilute mixtures that could be used in many end user applications like Hydrogen refueling stations for heavy duty Fuel cells vehicles, chemical industry thus reducing the cost of Hydrogen in its value chain.

Electrochemical hydrogen pumps (EHPs) offer a promising solution for efficient hydrogen separation and compression, essential for utilizing natural gas pipelines for transport. However, advancing EHP technologies is critical to overcoming current limitations and enabling a cost-effective, global hydrogen network

When I joined Los Alamos National Laboratory as a postdoctoral researcher in the team led by Yu Seung Kim—a renowned scientist in HT-PEM fuel cells and the creator of ion-pair membrane technology—I was entrusted with the challenging task of demonstrating the advantages of electrochemical hydrogen pumps (EHPs) over state-of-art PA-PBI systems as well as commercially established technologies like pressure swing adsorption (PSA) for hydrogen separation and purification. This involved tackling two experimental challenges: first, to establish a mass-transport-limit free current-voltage relationship to assess the activity and efficiency of the EHP device, and second, to demonstrate that EHPs can operate stably for thousands of hours at current density >3 A/cm2, even in the presence of impurity gases and low hydrogen concentrations. All the prior works based on low temperature EHPs and High temperature PA-PBI based EHPs have failed to show the hydrogen separation efficiencies at more than 5 A/cm2 current density and stable performance at >1 A/cm2 for over 100 hours. In fact, when I began the experiments with ion-pair membrane based EHPs, I also observed mass-transport limited current density of ~ 3-4 A/cm2 and the EHPs would immediately fail when running at current density more than 3 A/cm2. It took numerous experiments to figure out the exact cause of this failure- i.e. the limiting proton conductivity.

This is when I went back to my background of electrochemistry and tried to figure out the exact reason. As per as the electrochemical reactions are concerned, the anode and cathode in EHPs are probably the simplest electrochemical reactions known- HOR and HER. Both are single electron transfer reaction; and at anode gaseous H2 is the reactant while at cathode protons are the reactant. Our control experiments suggested that HOR was not the limiting factor at least for pure hydrogen feed at anode. But HER may be the limiting factor at higher current density because the components used in the MEA could only support limited proton conductivity to sustain high current densities beyond 3 A/cm2. However, when we draw corollary between this cathode reaction and the corresponding half-cell HER reaction in a H-Cell, we never observe mass-transport limited current density. Another corollary to draw was the HT-PEM fuel cell performance of the same membrane electrode assembly. Cathode side proton transport was not the limiting factor here since in the Fuel cell operation water is the by-product of the cathode reaction. This means, the proton conductivity is somewhat enhanced by the reaction byproduct itself. This advantage is not provided in the EHP operation.

I had many discussions with my mentor Yu Seung about these possibilities and designed few experiments to prove the dependency of proton conductivity on the EHP performance- stability and Polarization curve free of mass transport limited current. First, we used different ionomers with varying proton conductivity and monitor the limiting current density. Second, we used external device testing conditions i.e. provide water vapor at the cathode side (selectively) to compensate for the proton flux at higher current density. Using these two approaches, we could establish a correlation between the EHP performance limiting factors to the cathode side. Thus, I was able to successfully obtain higher current density ~ 14.5 A/cm2 and more than 1000 hours of stability at 3 and 5 A/cm2 current density for EHPs.

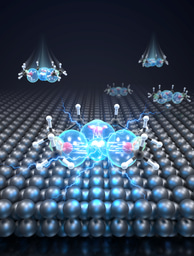

Figure: Electrochemical hydrogen pumps and voltage contribution for the performance of EHP. The methods to improve [proton conductivity – ionomer and selective humidification.

These findings highlight the potential of our EHP for efficient hydrogen separation and compression, enabling cost effective industrial hydrogen production and delivery. It offers a competitive alternative to industry standard PSA separation and conventional compression systems, promising improved energy efficiency and cost-effectiveness in the hydrogen supply chain.

LA-UR-25-21886

Follow the Topic

-

Nature Energy

Publishing monthly, this journal is dedicated to exploring all aspects of this on-going discussion, from the generation and storage of energy, to its distribution and management, the needs and demands of the different actors, and the impacts that energy technologies and policies have on societies.

Related Collections

With Collections, you can get published faster and increase your visibility.

Microgrids and Distributed Energy Systems

Publishing Model: Hybrid

Deadline: Mar 31, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in