Revolutionizing Microdevices: How Spin-Currents and Magnetostriction Unlock New Possibilities in Technology

Published in Bioengineering & Biotechnology and Materials

Microactuators are devices that operate on a microscopic scale to control precise movements and forces. They have applications in fields as diverse as medicine, robotics, automotive and aerospace. Microactuators are currently designed based on a variety of operating principles, such as electrostatic, magnetic, piezoelectric, thermal expansion and shape memory alloys. This makes it possible to select the optimum actuator for a particular application. Microactuators can operate with very high precision and fast response times, making them suitable for applications where minute manipulation is required. Due to their small size and low energy consumption, microactuators can be easily integrated into small devices and compact systems.

However, the production of microactuators with microstructures is technically complex and requires high-precision manufacturing techniques. Microactuators need to maintain high durability and reliability over long periods of use and under harsh environmental conditions, which poses significant design and material selection challenges. In battery-powered applications, such as portable systems, energy efficiency is also a key issue.

For example, micro-scanning mirrors are optical devices used to scan laser beams in LiDAR (Laser Imaging Detection and Ranging) in uncrewed vehicles and small robots. The light weight and low power consumption of micro-scanning mirrors are useful in LiDAR applications, but the small apertures of micro-scanning mirrors limit their application due to the weak light received. The power is insufficient to make larger aperture scanning mirrors and higher-power microactuators are needed. The lack of power of microactuators in ultrasonic elements and microspeakers is also an obstacle to the extension of their application ranges.

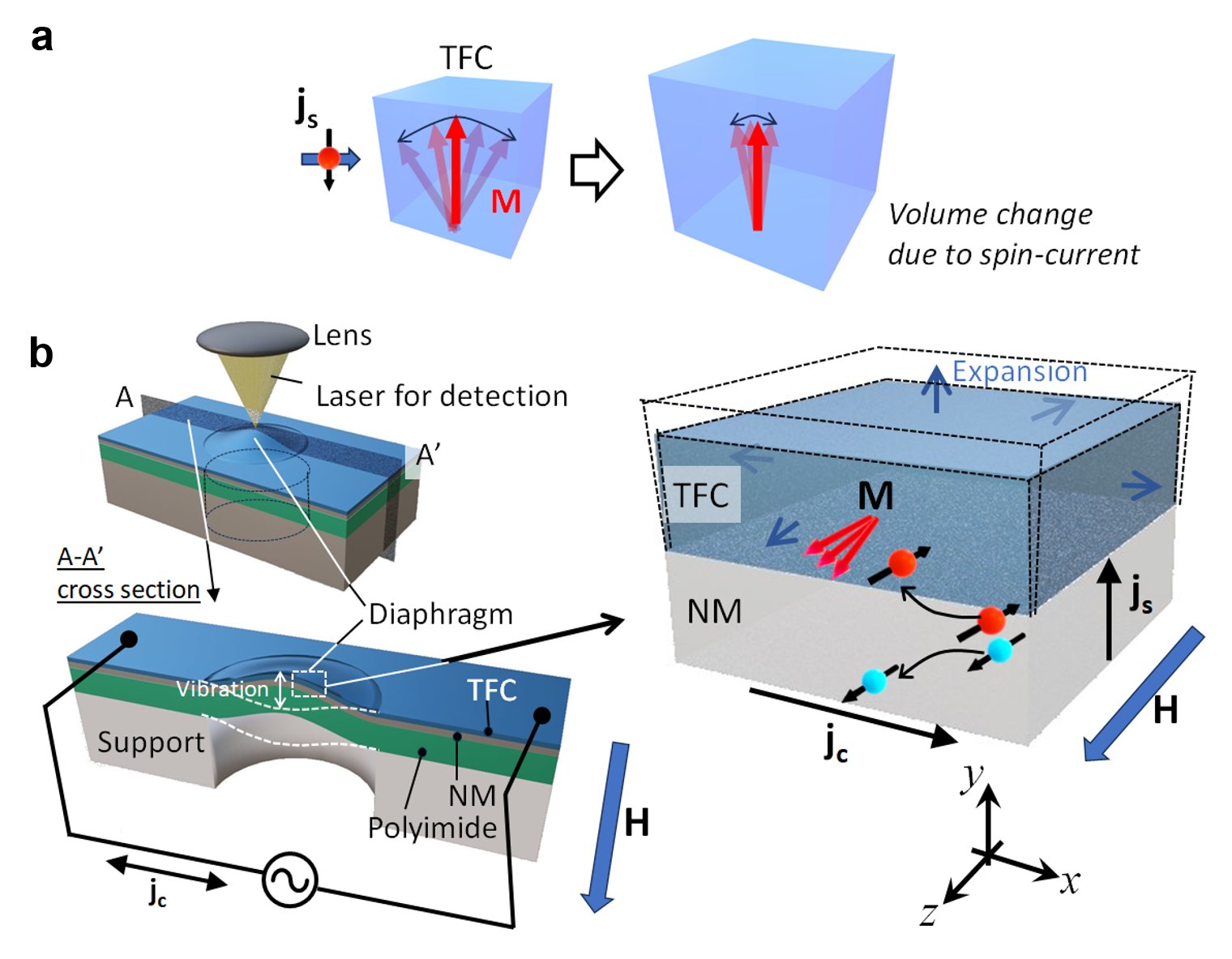

Fig. 1. Working principle and experimental method using the diaphragm actuator structures for evaluating the actuation performance of spin-current volume effect (SVE). a. A positive volumetric magnetostriction TbFeCo (TFC) film expands due to the reduction of spin fluctuations caused by the spin transfer torque under an external magnetic field. b. A schematic illustration of experimental setup using the TFC/NM/Polyimide diaphragm actuated by SVE. H, M, jc, and js denote the magnetic field, the magnetization of the TFC film, the charge current, and the spin-current. The volume of the TFC film can be modulated by the spin transfer torque via spin-current injection. Here, an electron with its spin (magnetic moment) antiparallel (parallel) to the magnetization M is injected into the TFC film. Thus, an alternating charge current flow in the TFC/NM films induces mechanical vibration in the diaphragm. The right-side figure shows the schematic when Pt is used as the NM layer.

This study demonstrates that the magnetization of a thin-film magnetic material can be controlled by injecting a spin-current and transferring angular momentum into the magnetic thin film, resulting in excellent driving properties. For the generation of the spin-current, Pt, which has large spin-orbit interactions, is used, and charge current flows into Pt to generate the spin-current, as shown in Fig. 1. The phenomenon that the inflow of a spin current into a magnetic thin film changes the volume of that film (spin-current volume effect) has been observed, but its driving capability was unknown. In this paper, it is reported that amorphous TbFeCo thin films exhibit the spin-current volume effect and can achieve very high power densities. This new driving principle provides microactuators that compensate for the lack of power, have better mechanical shock, require large displacements, are highly energy efficient, and can be fabricated using simple manufacturing methods. This microactuator has potential applications in medical devices, small robots, and communication devices etc.

Follow the Topic

-

Communications Engineering

A selective open access journal from Nature Portfolio publishing high-quality research, reviews and commentary in all areas of engineering.

Related Collections

With Collections, you can get published faster and increase your visibility.

Applications of magnetic particles in biomedical imaging, diagnostics and therapies

Publishing Model: Open Access

Deadline: May 31, 2026

Integrated Photonics for High-Speed Wireless Communication

Publishing Model: Open Access

Deadline: Mar 31, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in