Solar-driven sugar production directly from CO2

Published in Chemistry

Crop plants cultivation, essentially based on natural photosynthesis that converts water and atmospheric CO2 into carbohydrates, has been the primary way for food production for thousands of years. Nevertheless, the food production is severely limited by the efficiency of natural photosynthesis, as the energy conversion efficiencies to biomass for most crop plants are only ~1% or less. More crucially, traditional food production by cultivation is facing the challenges from sustainable development, such as overuse of chemical pesticides and fertilizers, as well as encountering geographical restrictions, such as global climate change, land scarcity, and shortage of fresh water. As such, new approaches to enhancing the efficiency for food production, while reducing the dependency on natural resources and avoiding environmentally harmful chemicals, are greatly desired to supplement the traditional food production.

From the viewpoint of sustainable development, solar energy should be utilized as the major energy input for efficient artificial synthesis of food directly from CO2 via elaborate design and integration of systems, overcoming the limitations of natural photosynthesis in crop plants. If achieved, such an approach would not only offer a promising sustainable approach for food production, but also promote carbon-neutral economy. This beautiful blueprint encounters with a grand challenge. Although significant progress has been made on chemical conversion of CO2 to C1 and C2 products (e.g., CO, CH4, HCOOH, C2H4, CH3CH2OH) through electrocatalysis or photocatalysis, it remains challenging to achieve sustainable synthesis of value-added food (e.g., long-chain sugars) by directly recycling CO2.

Recently, breakthroughs have been made in developing chemical-biological hybrid systems to achieve food production. However, even by genetic engineering, the complex metabolic networks existing inside microbial cells pose a grand challenge to the customization of carbonaceous products. Moreover, the commonly used model heterotrophic microorganisms (e.g., Escherichia coli, Saccharomyces cerevisiae) require sugars as necessary nutrients, which cannot fully achieve carbon neutrality. Alternatively, according to diverse upstream products from chemical CO2 conversion, the biological components in the hybrid system can be completely constructed in vitro by freely integrating different enzymatic reactions, which will be more favorable for customizable food production in contrast to in vivo metabolic pathway and have no consumption of carbonaceous nutrients.

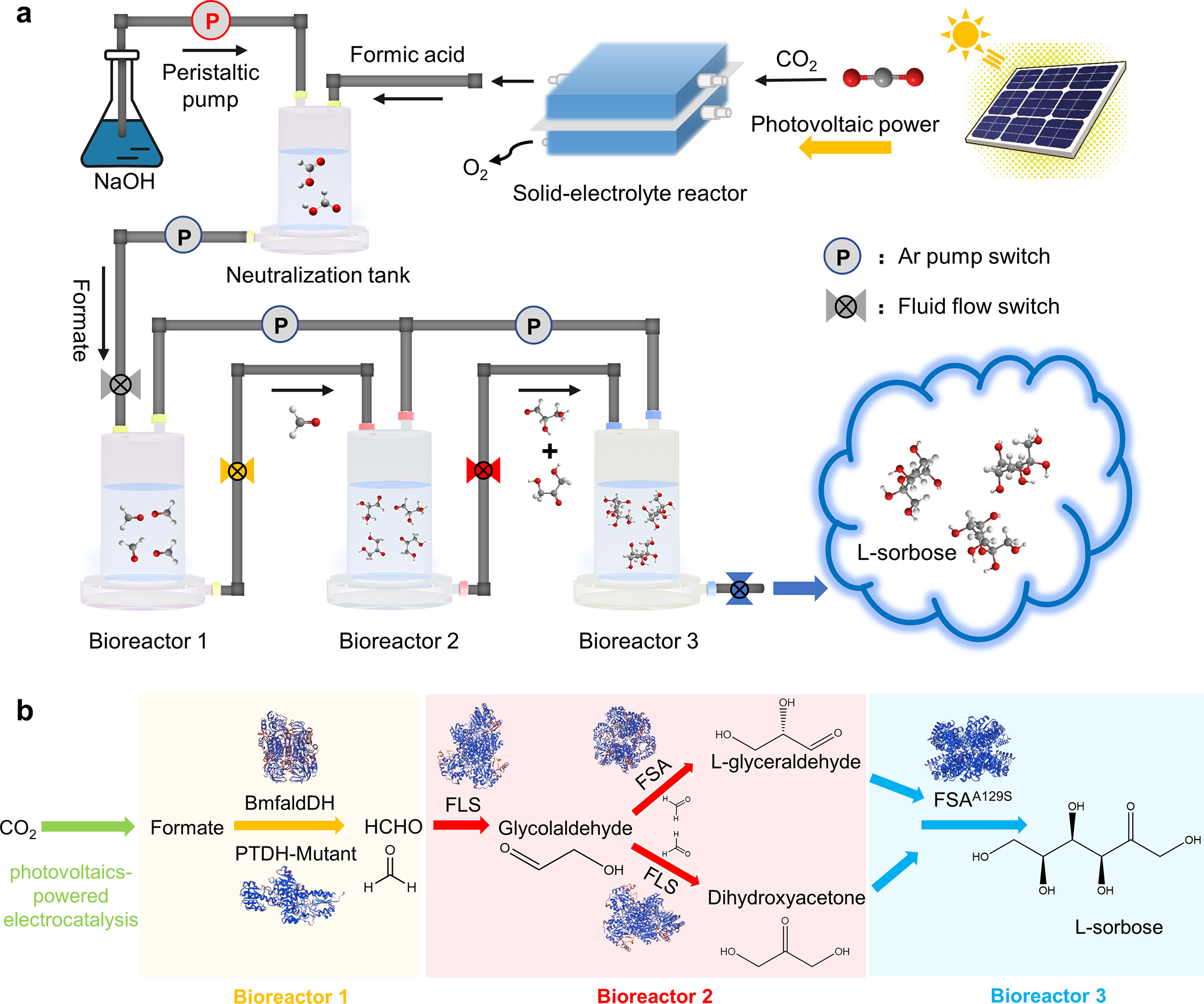

In our recent paper published in Nature Communications (https://doi.org/10.1038/s41467-024-46954-w), we report a hybrid electrocatalytic-biocatalytic flow system for achieving artificial synthesis of sugar directly from CO2, by coupling photovoltaics-powered electrocatalysis with spatially separate enzyme cascade platform (Fig. 1). Upon light irradiation, the high concentration of pH-adjusted formate solution generated by the light-driven electrocatalytic CO2 conversion module can be directly fed into our designed tandem bioreactors, which comprise a five-enzyme cascade platform to achieve the efficient and selective conversion of formate into C6 sugar—L-sorbose— a famous food additive as well as an important intermediate for industrial production of L-ascorbic acid.

Fig. 1 | Schematic illustration of the customizable electrocatalytic-biocatalytic flow system for solar-driven sugar production directly from CO2.

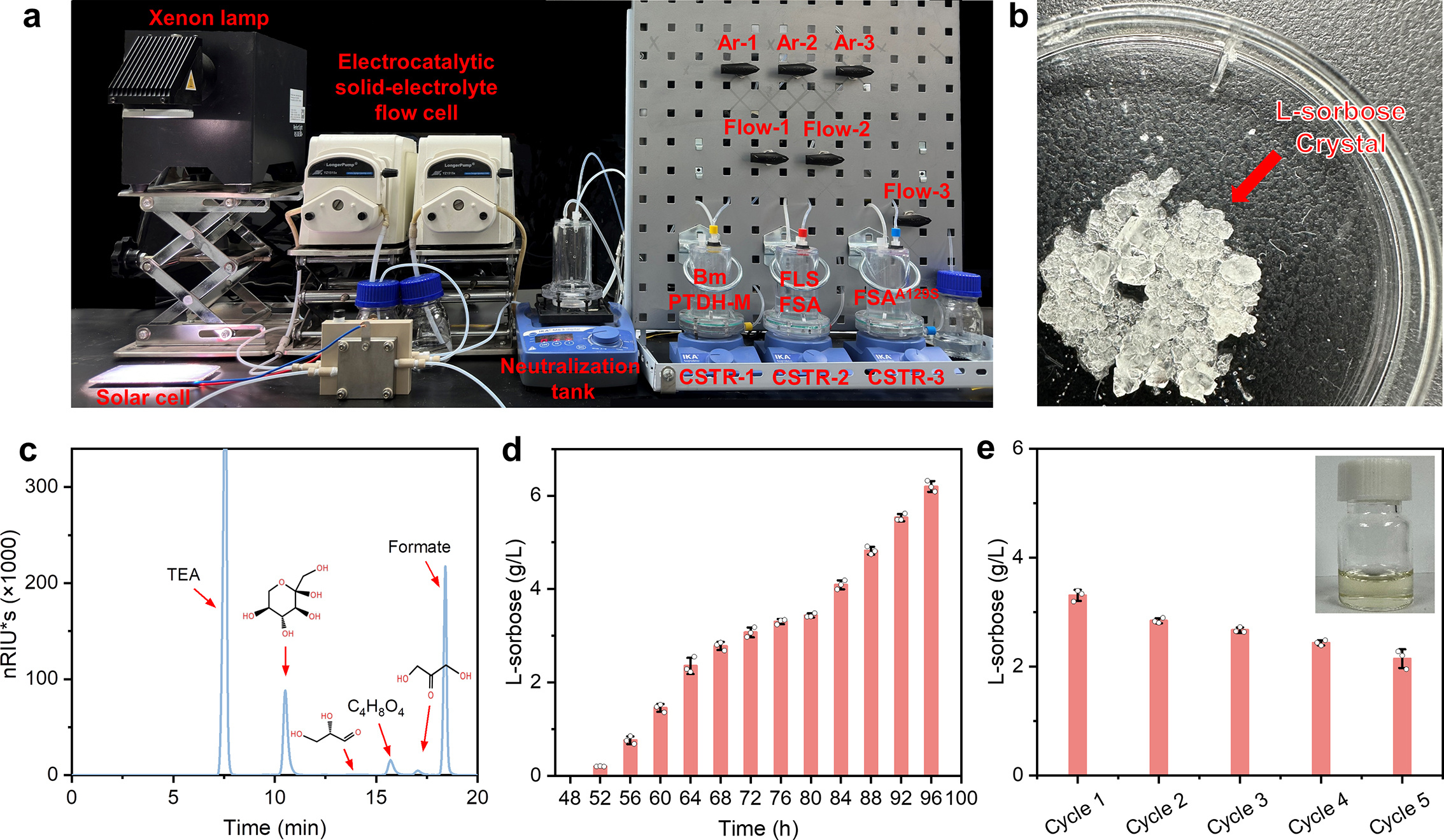

We then designed flow cascade reactors to implement the constructed electrocatalytic-biocatalytic system toward continuous solar-driven sugar production directly from CO2 (Fig. 2). The overall efficiency of CO2 conversion via biological approaches is restricted by mass transfer at the gas–liquid interface due to the low solubility of CO2 in water. Therefore, the approach that firstly achieves highly efficient conversion of CO2 into a soluble liquid C1 product (e.g., formic acid) by chemical electrocatalysis using gas diffusion electrode to overcome the mass transfer limitation, followed by the chemical transformations via biological enzyme cascade catalysis, is more feasible. To avoid the negative effect on downstream enzymatic catalysis by highly concentrated bicarbonate electrolyte, a porous solid-electrolyte reactor was employed to directly produce pure HCOOH solution, followed by adjusting the pH with cost-effective NaOH. Upon light irradiation, the high concentration of pH-adjusted formate solution generated by the light-driven electrocatalytic CO2 conversion module was directly fed into continuous stirred tank reactor (CSTR) for biocatalytic conversion.

Fig. 2 | Solar-driven sugar production from CO2 in electrocatalytic-biocatalytic flow system.

Through screening out highly efficient enzymes via genetic mutation and bioinformatics, our designed system enables the conversion of CO2 to L-sorbose with a yield of 105.0 mg/L/h and a solar-to-sugar energy conversion efficiency of 3.5% under standard solar light irradiation with CO2 as the only carbon source, outperforming natural photosynthesis by over three-fold. This efficiency can be further improved by employing a matched photovoltaic cell with higher efficiency.

This flow system can in principle be programmed by integrating diverse enzymes toward production of multifarious food (e.g., sugars, nutriments) from CO2. Furthermore, as an important intermediate in traditional “two-step fermentation” process for industrial production of L-ascorbic acid, the produced L-sorbose from CO2 allows the direct production of L-ascorbic acid directly from CO2. Our approach to food production will particularly be available for applications in confined environments and physical space, such as space station or the region with atrocious circumstance or finite agricultural lands on earth. In addition, beyond being driven by light, our flow system could also be powered by stored electricity or driven by other renewable electricity such as wind turbines, thus providing great potential for widespread and large-scale practical application. This work provides great opportunities for revolutionizing traditional farming and building a sustainable carbon-neutral food manufacturing industry.

Follow the Topic

-

Nature Communications

An open access, multidisciplinary journal dedicated to publishing high-quality research in all areas of the biological, health, physical, chemical and Earth sciences.

Related Collections

With Collections, you can get published faster and increase your visibility.

Women's Health

Publishing Model: Hybrid

Deadline: Ongoing

Advances in neurodegenerative diseases

Publishing Model: Hybrid

Deadline: Mar 24, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in