An Ultrasonic Microrobot Enabling Ultrafast Bidirectional Navigation in Confined Tubular Environments

Published in Bioengineering & Biotechnology and Materials

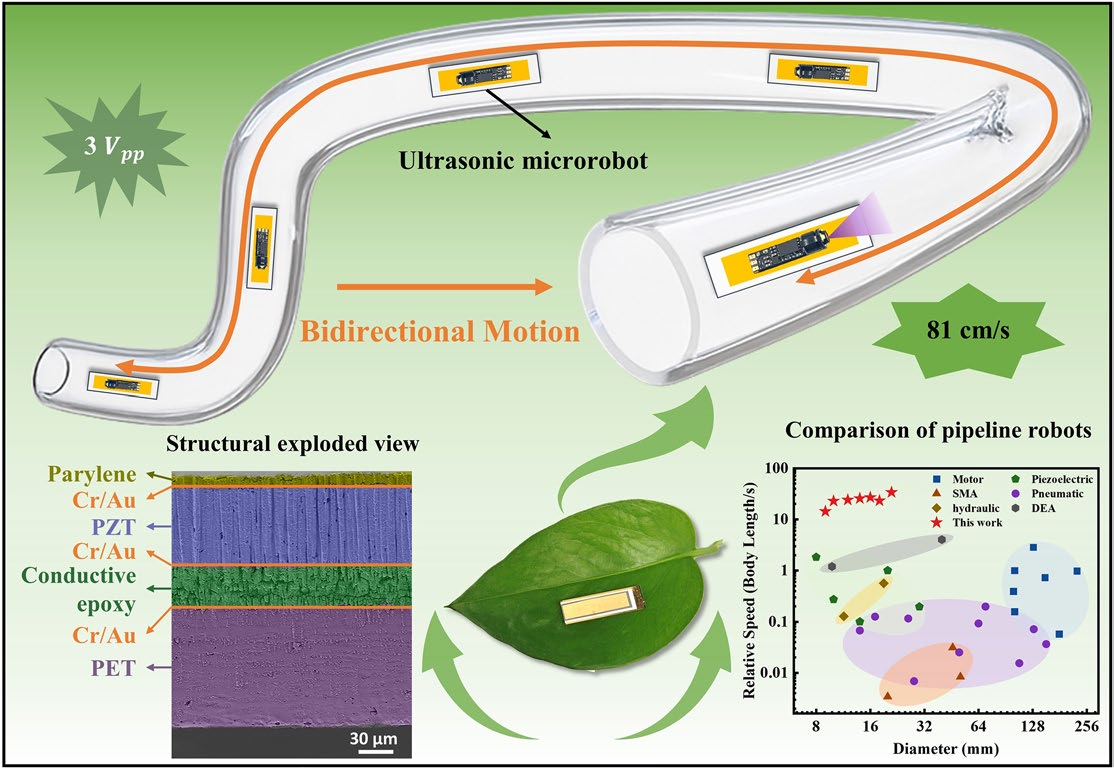

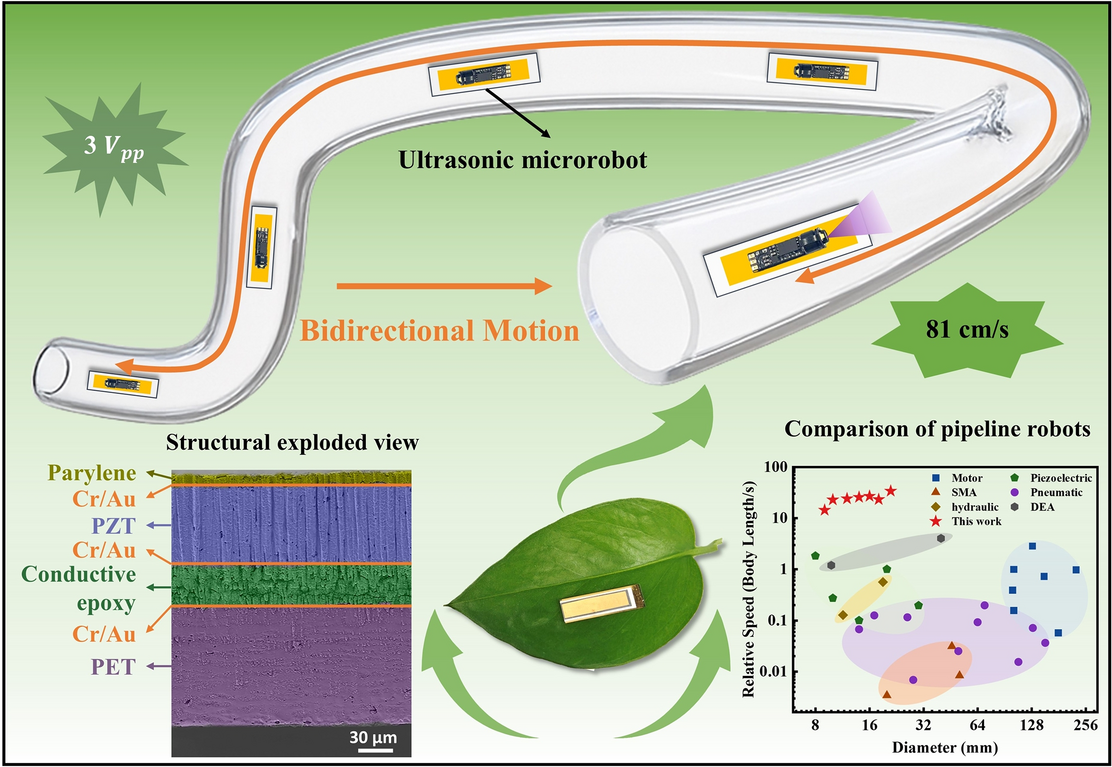

A research team led by Professor Bin Yang from Shanghai Jiao Tong University has developed an ultrasonic microrobot capable of ultrafast bidirectional navigation in confined tubular environments, as reported in Nano-Micro Letters. By integrating frequency-modulated ultrasonic actuation with a flexible piezoelectric composite structure, this work sets a new benchmark for miniaturized robotic inspection systems.

Design Concept

- Bio-Inspired Motion: Inspired by the centipede’s retrograde wave gait, the robot converts ultrasonic vibrations into traveling bending waves, generating controllable thrust through frictional coupling with pipe walls.

- Ultrathin Piezoelectric Structure: The robot integrates a thinned lead zirconate titanate (PZT) film with a flexible PET substrate via MEMS fabrication, encapsulated by a parylene-C layer. The compact design (24 mm × 7 mm × 210 μm, 80 mg) ensures high flexibility and adaptability.

- Frequency-Modulated Direction Control: Bidirectional locomotion is achieved simply by tuning the driving frequency, allowing seamless forward and backward motion without structural adjustment.

Performance Achievements

- Record Speed and Low Voltage: The microrobot reaches a maximum speed of 81 cm s-1, surpassing all reported piezoelectric microrobots. It operates at an exceptionally low driving voltage of 3 Vp-p, two orders of magnitude below dielectric elastomer systems.

- High Adaptability: It maintains stable movement in 4 mm-high pipes, climbs slopes up to 24.25°, and carries loads over 36 times its own weight.

- Environmental Versatility: The robot performs robustly in glass, stainless steel, and PVC pipelines, and even moves across water surfaces, demonstrating superior sealing and environmental tolerance.

Functional Demonstrations

- Real-Time Visual Inspection: A micro-endoscope camera enables real-time imaging inside confined pipelines, proving its potential for internal inspection and diagnostics.

- Application Potential: The system offers a powerful platform for pipeline inspection, medical microdevices, and microfluidic monitoring, where compact and agile robots are essential.

Future Outlook

- Toward Autonomous Systems: Future designs will integrate onboard power units, wireless modules, and micro-batteries for untethered, autonomous operation.

- Expanded Capabilities: Combining sensing, imaging, and manipulation functions will transform this design into a multifunctional micro-inspection system.

With its ultrathin architecture, low power demand, and scalable fabrication, this microrobot establishes a foundation for next-generation intelligent microrobotics in industrial and biomedical applications.

Follow the Topic

-

Nano-Micro Letters

Nano-Micro Letters is a peer-reviewed, international, interdisciplinary and open-access journal that focus on science, experiments, engineering, technologies and applications of nano- or microscale structure and system in physics, chemistry, biology, material science, and pharmacy.

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in