From pore to process: an industrially promising application for MOFs in separating the most potent greenhouse gas

The effective separation of sulfur hexafluoride (SF6)—a critical industrial insulating gas and the most potent greenhouse gas—is an urgent challenge in the electricity industry. Here, we address the pressing need for energy-efficient alternatives to conventional SF6 separation technologies, such as low-temperature liquefaction and distillation, by developing highly efficient composite pellet adsorbents based on the low-cost metal-organic framework Al(fum) and designing a corresponding two-stage vacuum temperature swing adsorption (VTSA) process.

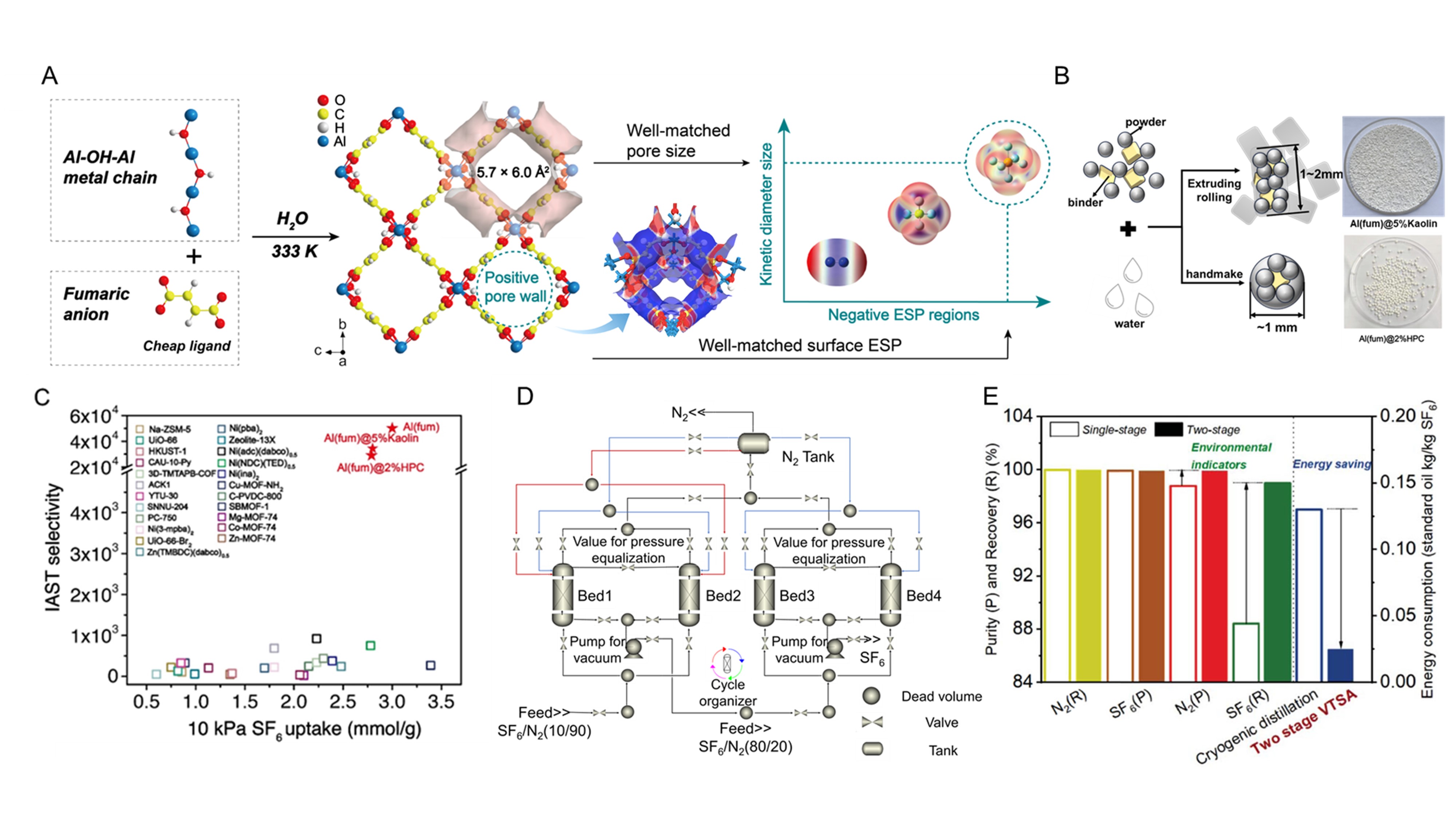

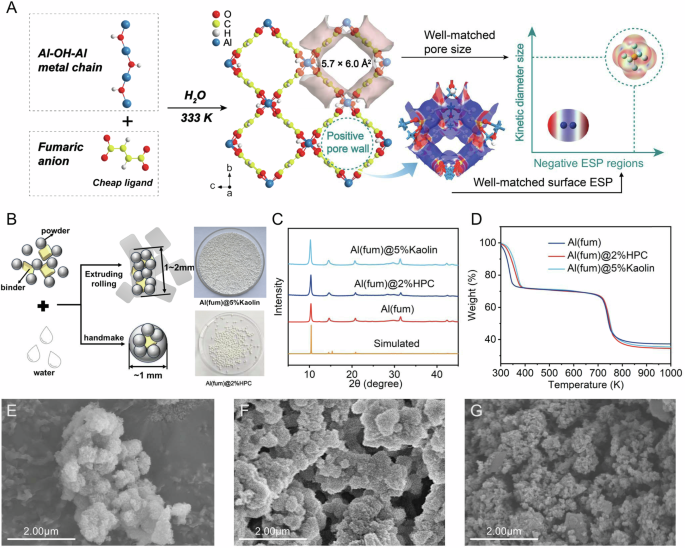

Figure 1. A The crystal structure of Al(fum) with 1D channels, the surface electrostatic potential of the Al(fum) framework, and the SF6 and N2 molecules with a scale spanning. B The process of shaping Al(fum) powder with Kaolin. or HPC binder. C Comparison of the SF6 uptakes at 10 kPa and the IAST selectivities of SF6/N2 mixture (10/90, v/v) at 1 bar on different adsorbents at 298 K. D Schematic model of the two-stage VTSA process. E Simulation results of single-stage and two-stage VTSA and energy consumption for two-stage VTSA and cryogenic distillation

What are key take-home messages from our study?

A: Our study addresses this challenge in the context of the efficient and sustainable recovery of low-concentration SF6 (the most potent GHG of all gases) from its mixtures with N2, a critical step for the GHG capture and recycling in the electricity industry. From a chemical perspective, the record SF6 adsorption capacity and separation selectivity of powder adsorbent (Al(fum)) were achieved by leveraging a suitable pore environment that integrates electrostatic potential and pore size matching. From an engineering perspective, the Al(fum) pellet adsorbents mass-produced via a mechanized wet granulation technology have excellent stability (stable to air, water, heat and abrasion resistant) and recyclability. From a process design perspective, simulated two-stage VTSA process based on the Al(fum) pellet demonstrates that the proposed approach meets both environmental and electrical equipment safety standards while achieving SF6 recovery and purity simultaneously exceeding 99.9%, with energy consumption reduced by more than 80% compared to cryogenic distillation.

What is the key breakthrough of the research published on Nature Communications by the team from Zhejiang University?

A: We have established an industrially promising application for MOFs through a combination of novelty in both adsorbent and process design, based on insights from how frameworks with specific pore chemistry and structure respond to enhance their selectivity for target molecules to critical considerations for real-world industrial applications. This work would pave the way for the development of industrially promising porous media and process for the energy-efficient capture of potent greenhouse gases, as well as other challenging separation tasks, which are critical to the application of chemical engineering.

Who led the research?

A: The research was led by Prof. Qiwei Yang and Dr. Tian Ke as the conceptual designer and project supervisor, and Jinjian Li and Yuting Chen as the co-first author. It represents a collaboration between the Zhejiang University and Institute of Zhejiang University-Quzhou.

For more details, please check out our paper on Nature Communications "Efficient continuous SF6/N2 separation using low-cost and robust metal-organic frameworks composites" (DOI: https://doi.org/10.1038/s41467-025-56031-5).

Follow the Topic

-

Nature Communications

An open access, multidisciplinary journal dedicated to publishing high-quality research in all areas of the biological, health, physical, chemical and Earth sciences.

Your space to connect: The Fuel cell technologies Hub

A new Communities’ space to connect, collaborate, and explore research on Electrochemistry, Chemical Engineering, and Fuel Cells!

Continue reading announcementRelated Collections

With Collections, you can get published faster and increase your visibility.

Women's Health

Publishing Model: Hybrid

Deadline: Ongoing

Advances in neurodegenerative diseases

Publishing Model: Hybrid

Deadline: Mar 24, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in