Aerogels are attractive light-weight materials with superior thermal insulation properties. But they are often fragile and their synthesis is slow, complicated, and expensive. For practical applications, the research of aerogels should not only focus on the properties, but also on rapid, cheap, scalable synthesis methods. This motivated the collaborations between our group under advisory of Prof. Jiangtao Li at Technical Institute of Physics and Chemistry, CAS, and Prof. Yanhao Dong’s group at Tsinghua University.

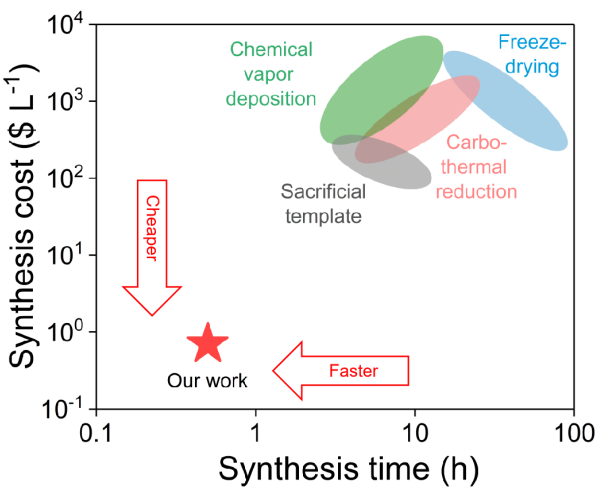

The story began with an occasional discovery that combustion synthesis of Si-polytetrafluoroethylene (PTFE) system gave a large cake. The very first experiment was designed to synthesize SiC powders but somehow we obtained a monolithic-form sample with very low density. We later on realized what we got is a liter-scale SiC aerogel. Remarkably, all that takes is a flame and the conversion from raw materials to final aerogel products is surprisingly fast. Because of the extreme simplicity of the synthesis method, the cost is also very low. Based on the currently published articles on SiC aerogels, we estimated the synthesis cost and time of our method. The 0.5 h synthesis time and 0.7 $ L-1 synthesis cost are orders of magnitude different from other preparation methods (shown in Fig. 1), which is what we consider to be the most valuable aspect of the work on combustion synthesis of SiC aerogels.

Figure 1. Comparison of the synthesis time and cost between our method and the ones reported in the literature. For details and reference, check Figure 1g of our manuscriptref. 1.

The prepared SiC aerogel is a layered structural material composed of numerous SiC nanowires that are interwoven and stacked. During the propagation of the combustion wave, the SiC nanowires form stable cross-linking points through local sintering, thereby constructing a three-dimensional continuous interconnected network. The layered structural characteristics of the SiC aerogel, combined with its high porosity of up to 99.6% and all-ceramic composition, confer a series of good macroscopic physical properties. These include compressibility over a wide temperature range (from−196 ℃ to 1100 ℃), indicating the material's excellent temperature stability. Furthermore, the SiC aerogel exhibits an ultra-low thermal conductivity at room temperature (0.027 W m−1 K−1).

Our work on SiC aerogels prepared by a fast, efficient and cost-effective synthesis method is unlike any other articles on SiC aerogels in recent years, and it is a new breakthrough and development. This method of combustion synthesis might be broadened to more material systems to synthesize e.g. carbides, oxides, nitrides, MAX-phase aerogels, and so on. In the choice of raw material system, the occurrence of gas-solid or gas-gas reaction during the reaction process is very critical for the generation of ceramic bulk materials. The subsequent shift of research focus to the synthesis method may bring more new discoveries to the field of aerogels.

Note: The experiment has the characteristics of strong heat release, high combustion temperature, large degree of gasification of the reactant, rapid pressure increase of the gas inside the reactor along with material volume expansion and reaction heat release, and has certain risks. It is recommended that researchers who are interested in this work and want to verify it themselves first evaluate the pressure vessel capacity, starting with a small amount of reactants.

Reference

- Han, L., Chen, S., Li, H. et al. Rapid and inexpensive synthesis of liter-scale SiC aerogels. Nat Commun15, 6959 (2024).https://www.nature.com/articles/s41467-024-51278-w

Follow the Topic

-

Nature Communications

An open access, multidisciplinary journal dedicated to publishing high-quality research in all areas of the biological, health, physical, chemical and Earth sciences.

Related Collections

With Collections, you can get published faster and increase your visibility.

Women's Health

Publishing Model: Hybrid

Deadline: Ongoing

Advances in neurodegenerative diseases

Publishing Model: Hybrid

Deadline: Mar 24, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in